Special-shaped beam formwork quick mounting and dismounting structure using electromagnetic force and mounting and dismounting method thereof

A special-shaped beam, electromagnetic force technology, applied in the direction of formwork/formwork member, formwork/formwork/work frame, formwork/formwork/work frame connector, etc., can solve problems such as material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

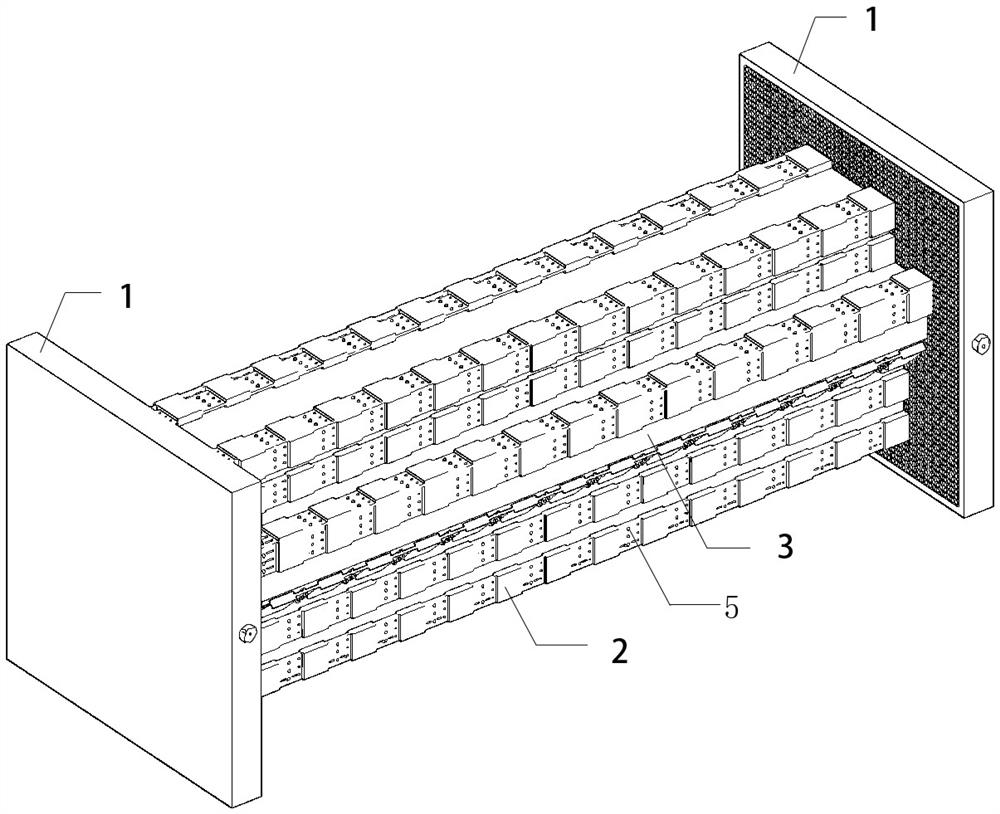

[0057] Examples see Figure 1 to Figure 4 As shown, the rapid installation and disassembly structure of special-shaped beam formwork using electromagnetic force and its installation and removal method,

[0058] The rapid installation and disassembly structure of the special-shaped beam formwork using electromagnetic force, including a pair of fixed plates 1, a shaped block 2 and a variable-angle fixed block 4 that are magnetically attracted between the pair of fixed plates 1 along the cross-sectional shape of the special-shaped beam and sandwiched between The template 3 between the shaping fast 2 and the variable angle fixed block 4.

[0059] see Figures 5 to 7 As shown, the fixed plate 1 includes a flat rectangular shell 1.1, a shoe-shaped iron core 1.2 arranged in the shell 1.1, a coil 1.3 wound on the shoe-shaped iron core 1.2, a controller 1.4 connected with the coil 1.3, and a controller 1.4 arranged on the control panel. The current stepless adjustment switch 1.5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com