Stamping type wood composite board punching device

A punching device and stamping technology, which is applied in wood stamping and other directions, can solve the problems of hole position deviation and failure to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

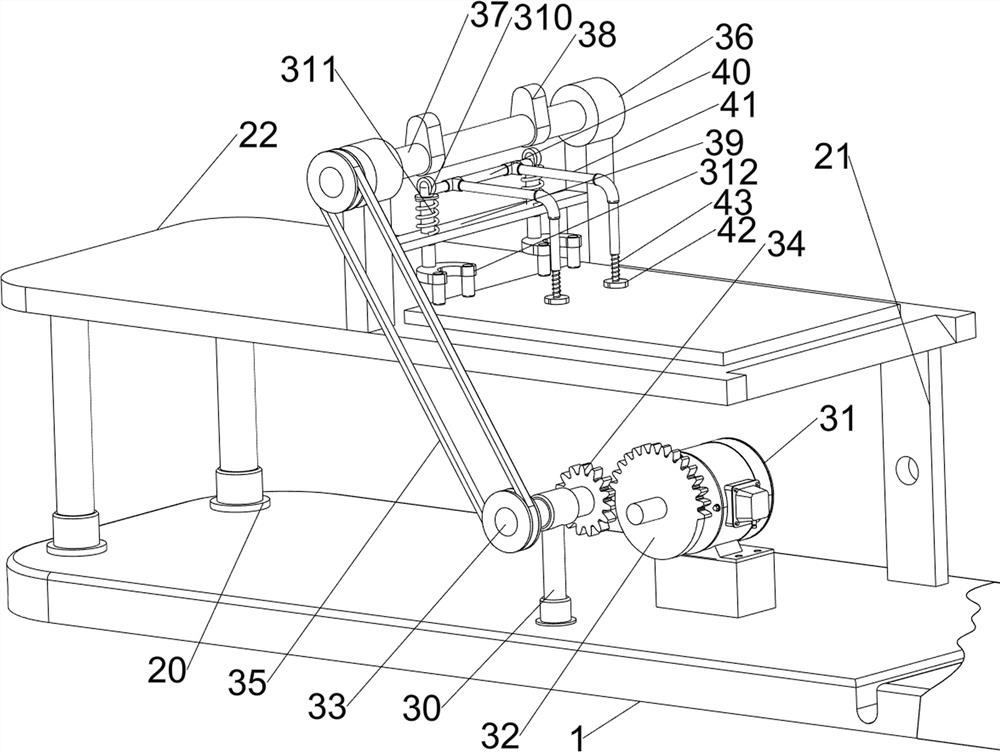

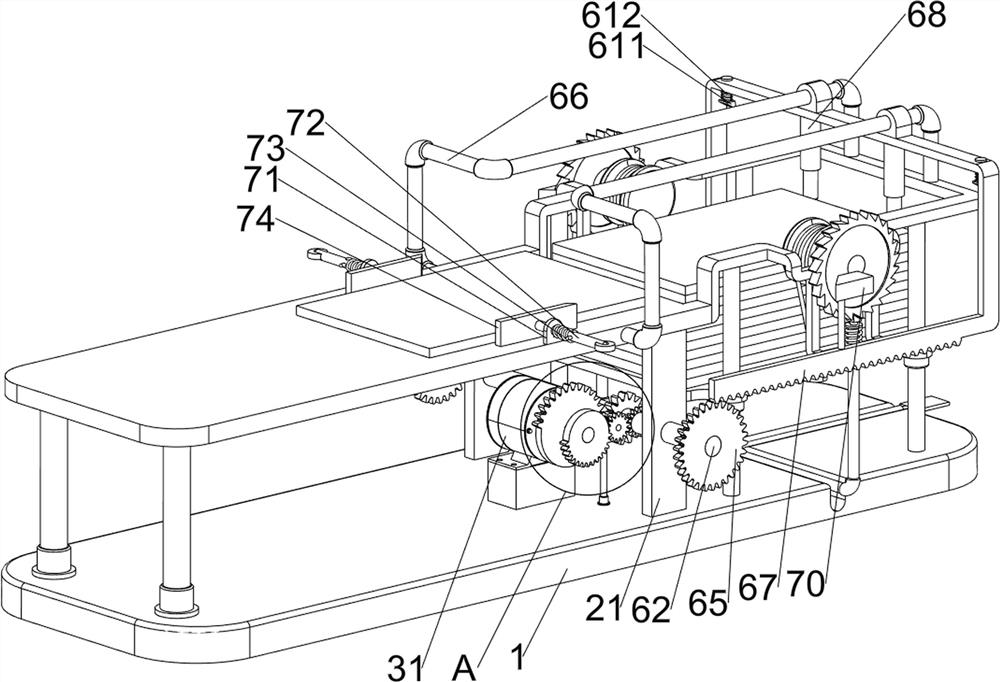

[0064] A punching type wood composite board punching device, such as figure 1 As shown, it includes a bottom plate 1 , a supporting mechanism 2 and a punching mechanism 3 . The top of the bottom plate 1 is provided with a supporting mechanism 2 , and the supporting mechanism 2 is provided with a punching mechanism 3 .

[0065] like figure 2 As shown, the support mechanism 2 includes a support column 20, a mounting plate 21 and a workbench 22, the top left side of the bottom plate 1 is provided with a support column 20 symmetrically front and rear, the top right side of the bottom plate 1 is provided with a mounting plate 21 symmetrically front and rear, and the top of the mounting plate 21 is provided A workbench 22 is connected with the top of the support column 20 .

[0066] like figure 2As shown, the punching mechanism 3 includes a first bearing seat 30, a motor 31, a first missing gear 32, a first rotating shaft 33, a first gear 34, a pulley set 35, a second bearing se...

Embodiment 2

[0069] On the basis of Example 1, as figure 2 As shown, it also includes a fixing mechanism 4, the fixing mechanism 4 includes a second connecting rod 40, a pressing rod 41, a pressing head 42 and a second spring member 43, and a second connecting rod is connected between the upper side of the first connecting rod 310 40. There are pressure rods 41 on both the front and rear sides of the second connecting rod 40, and a pressure head 42 is slidably provided in the pressure rod 41, and a second spring member 43 is connected between the pressure rod 41 and the pressure head 42.

[0070] like image 3 As shown, it also includes a feeding mechanism 5. The feeding mechanism 5 includes a fixed column 50, a feeding plate 51, a mounting frame 52, a rope pulley 53, a pulling rope 54, a ratchet wheel 55, a first installation rod 56, a first card The teeth 57, the third spring member 58 and the pedal 59, four fixing columns 50 are evenly arranged on the right side of the top of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com