Waste recycling and reusing device for green building construction and using method thereof

A waste recycling and green building technology, applied in chemical instruments and methods, solid waste removal, magnetic separation, etc., can solve the problems of inconvenient transportation and sorting, inability to disassemble cleanly, long working hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

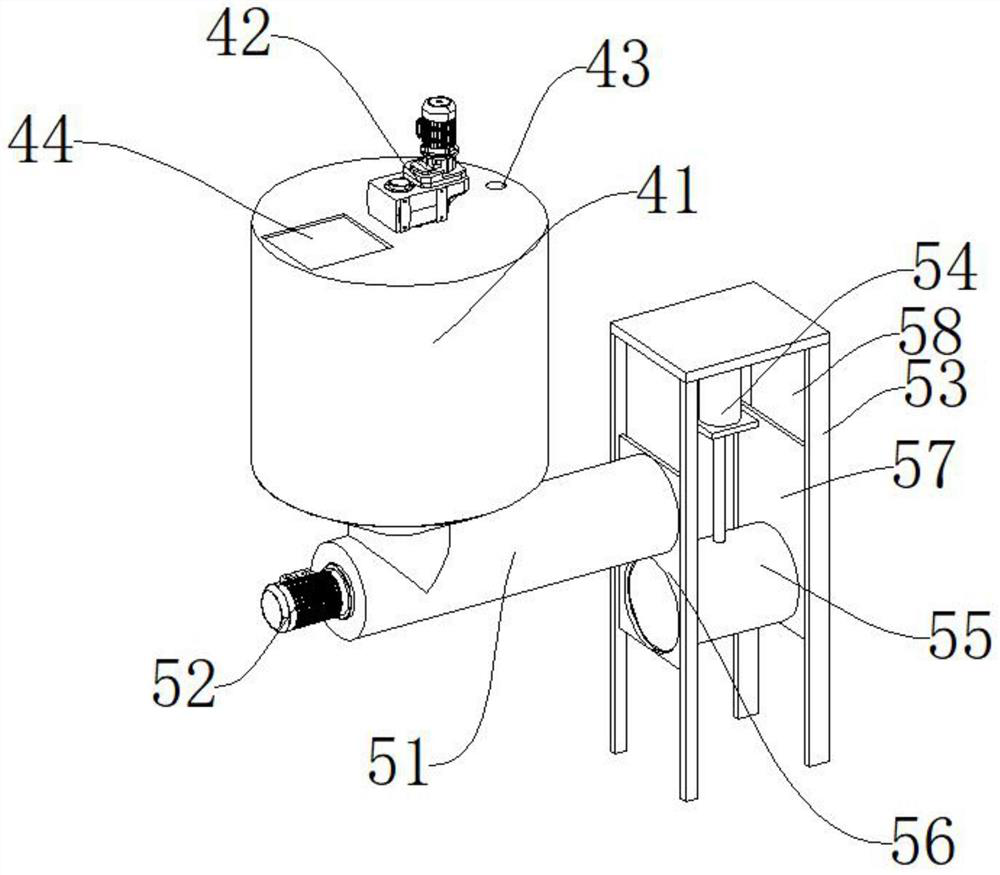

[0056] Such as Figure 1-Figure 10 As shown, the waste recycling device for green building construction includes a cutting mechanism 1, a crushing mechanism 2, a separation mechanism 3, and a stirring mechanism 4. The lower end of the cutting mechanism 1 is connected with a crushing mechanism 2, and the discharge end of the crushing mechanism 2 is provided with A separation mechanism 3, the lower end of the separation mechanism 3 is connected to the stirring mechanism 4, the discharge end of the stirring mechanism 4 is provided with an extrusion mechanism 5, and the crushing mechanism 2 is connected to the separation mechanism 3 through a linkage mechanism 6;

[0057] The cutting mechanism 1 includes a feed hopper 11, a cutting box 12, a rotating disc 13, and a rocker arm 14. The lower end of the feeding hopper 11 is connected to the cutting box 12. A matching knife 17 is arranged inside the cutting box 12, and a cutting knife 16 is provided at the front end of the matching kni...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is:

[0065] Such as Figure 11 As shown, the linkage mechanism 6 includes a linkage shaft 62, a linkage bevel gear 611, and a driven bevel gear 612. The linkage shaft 62 is connected to one side of the separation box 31, and the linkage shaft 62 and the crushing main shaft 24 are all connected with a linkage bevel gear 611. A connecting rod 613 is arranged between the bevel gears 611, and the linkage bevel gear 611 and the linkage rod 613 are connected through a passive bevel gear 612, and the crushing main shaft 24 transmits power to the linkage shaft 62 through the linkage bevel gear 611 and the linkage rod 613, thereby driving The separation conveying shaft 33 is rotated.

[0066] A method for using a waste material recovery and reuse device for green building construction, comprising the following steps:

[0067] a. Pour the construction waste into the feed hopper 11, and then start the first motor 21. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com