Three-tower two-effect rectification system and recovery method for NMP waste liquid

A recovery method, waste liquid technology, applied in separation methods, chemical instruments and methods, steam condensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

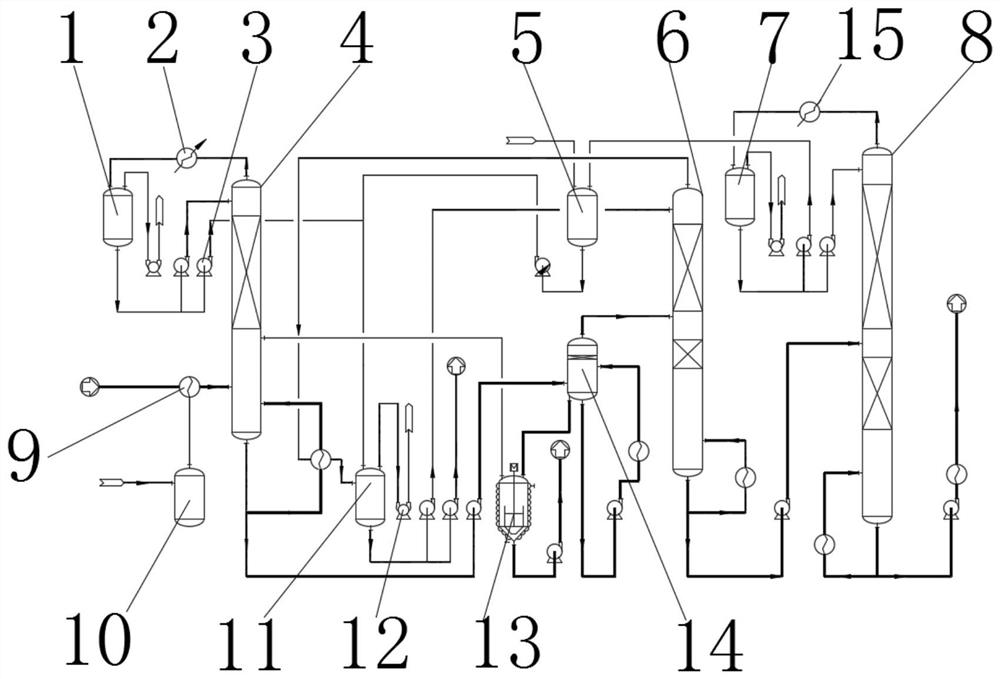

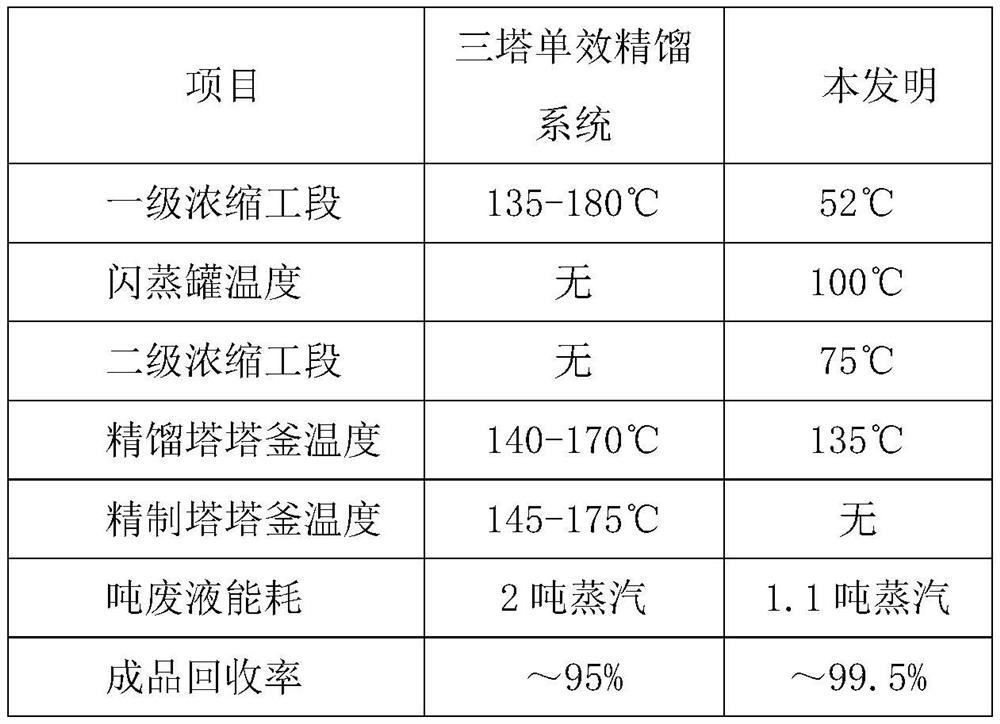

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0043] A kind of recovery method of NMP waste liquid, NMP recovery in the waste liquid comprises the following steps:

[0044] Step 1: The waste liquid containing NMP is pumped into the feed preheater through the waste liquid pump, and then enters the first-stage concentration tower after being preheated by the steam flashed by steam condensate;

[0045] Step 2: After preheating, the waste liquid enters the primary concentration tower for the first dehydration and concentration. The temperature at the top of the primary concentration tower is 45.5°C, and the corresponding temperature of the tower kettle is 52°C;

[0046] Step 3: After being dehydrated and concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com