Check valve arrangement and motor vehicle vacuum pump

A technology of check valves and valve seats, applied in the direction of valve devices, machines/engines, components of pumping devices for elastic fluids, etc., capable of solving problems such as low effective flow cross-sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

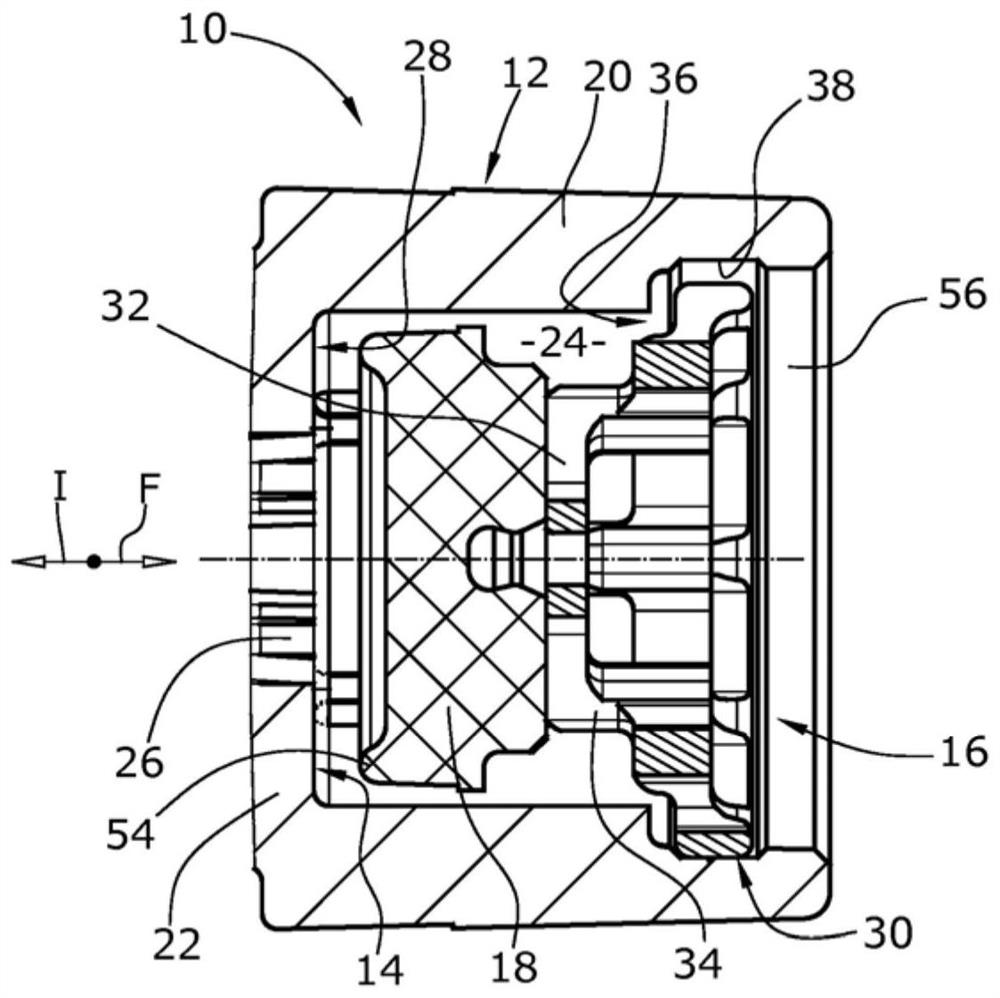

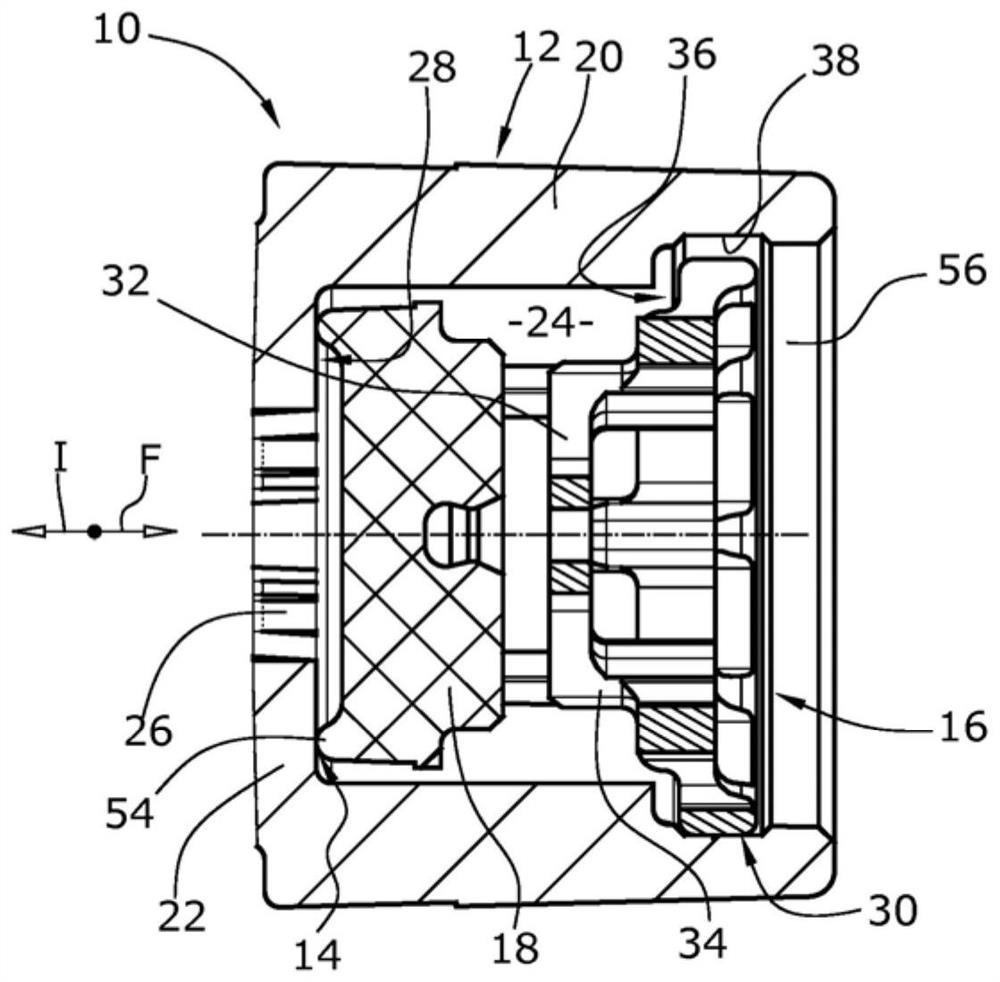

[0027] The illustrated check valve arrangement 10 comprises a pot-shaped valve housing 12 having an integral valve seat portion 14, a valve travel limiter 16 fixed within the valve housing 12, and a valve travel limiter 16 loosely arranged within the valve housing 12. The disc-shaped valve body 18.

[0028] The valve housing 12 includes a cylindrical housing side wall 20 and a transverse housing base 22 . The housing sidewall 20 radially defines a valve body chamber 24 and the housing base 22 defines the valve body chamber 24 in a first axial direction. The housing base 22 is provided with a valve inlet opening 26 and defines a valve seat portion 14 radially surrounding the valve inlet opening 26 . Accordingly, the valve seat portion 14 is located at the first axial end portion 28 of the valve body chamber 24 .

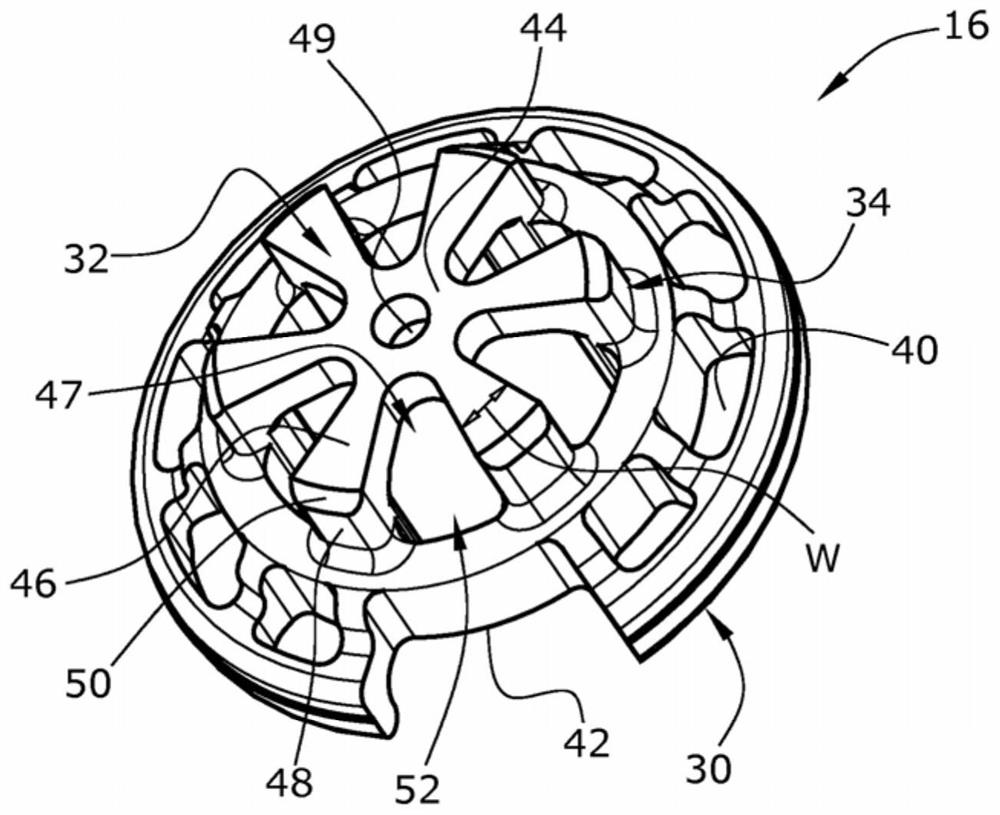

[0029]The valve travel limiter 16 includes a support ring 30 , a platform structure 32 axially protruding from the axial side of the support ring 30 facing the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com