Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., which can solve the problems of increased rolling resistance and deterioration of riding comfort, so as to reduce rolling resistance, improve riding comfort, The effect of suppressing fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

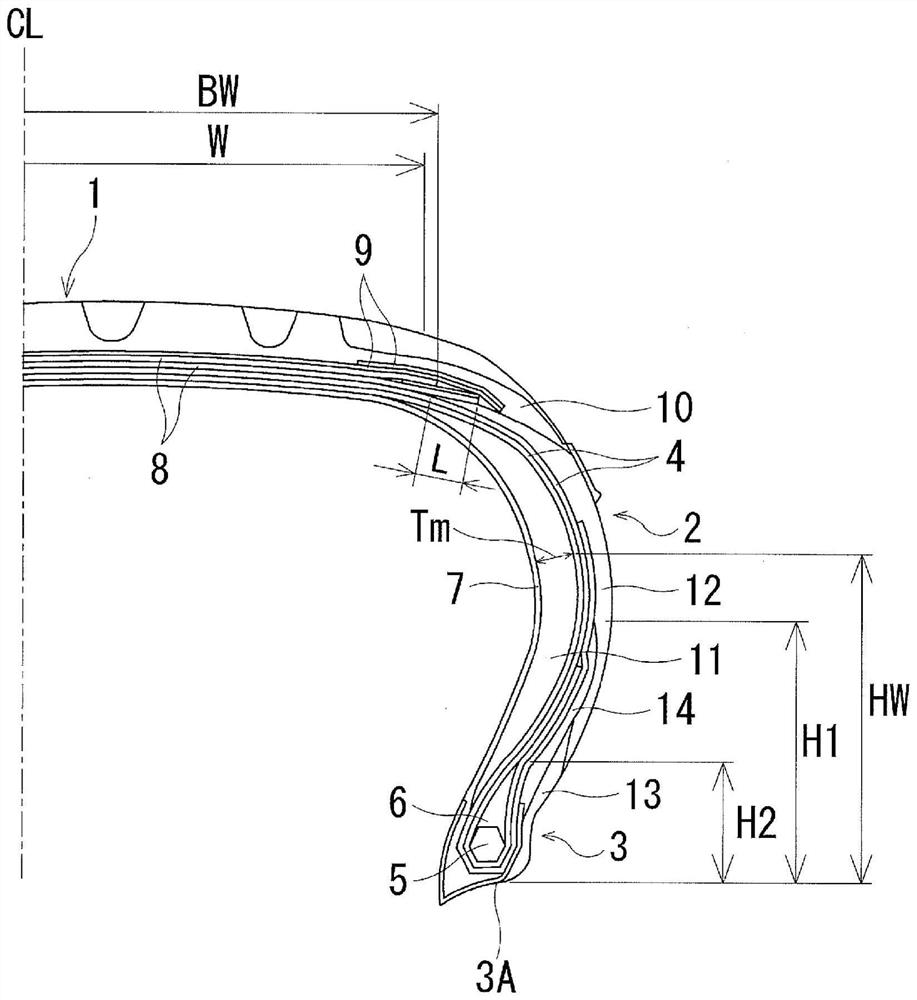

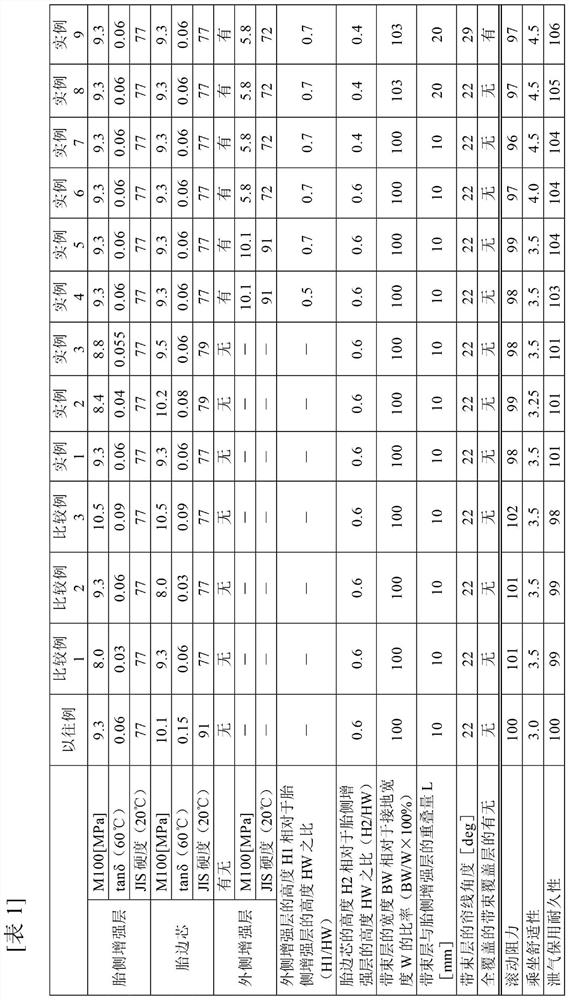

[0040] Pneumatic tires were produced in the conventional examples, comparative examples 1 to 3, and examples 1 to 9 in which the following parameters were set as shown in Table 1: M100, tan δ( 60°C) and JIS hardness (20°C); the presence or absence of the outer reinforcement layer; the M100 and JIS hardness (20°C) of the rubber constituting the outer reinforcement layer; the height H1 of the outer reinforcement layer relative to the height HW of the sidewall reinforcement layer Ratio (H1 / HW); the ratio of the height H2 of the bead filler to the height HW of the sidewall reinforcing layer (H2 / HW); the ratio of the width BW of the belt layer to the ground contact width W (BW / W×100% ); the overlapping amount L of the belt layer and the sidewall reinforcement layer; the cord angle of the belt layer; and the presence or absence of a full-coverage belt cover layer. The pneumatic tire has a tire size of 235 / 60RF18, and includes: a tread portion extending in the tire circumferential di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com