Cored induction furnace

An induction furnace and inductor technology, used in furnaces, charge materials, crucible furnaces, etc., can solve the problems of poor temperature stability of drawing and casting, fast heat conduction of ramming materials, and large furnace chamber of heat preservation furnace, so as to improve the heat preservation effect and service life. The effect of improving and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

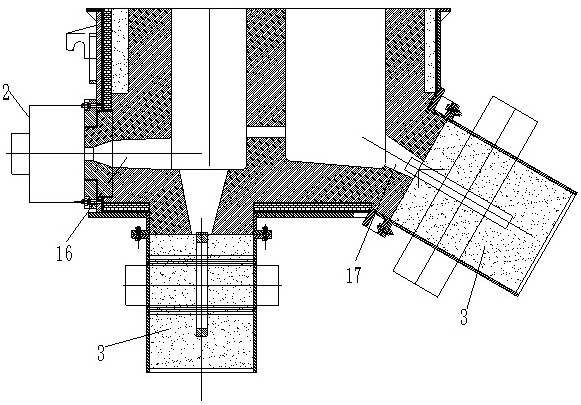

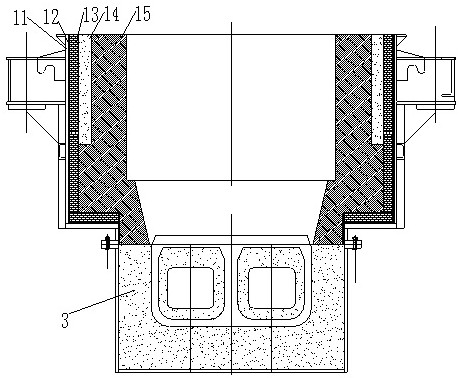

[0023] The composite silicon ramming material 14 has a thickness of 100cm and a height of 500cm at the corresponding position of the furnace mouth 16; a thickness of 80cm at the corresponding position of the core sensor installation opening 17, and a height of 500cm, and a thickness of 80cm at other positions. ㎝, the height is 700㎝;

[0024] The furnace volume of the holding furnace is 0.45 m³, the furnace volume of the melting furnace is 0.58 m³, and the furnace mouth slope is 3 。 , melting bottom slope 6 。 .

[0025] The unit power consumption of the billet in this embodiment is 424KW.h / t, the quality of the billet casting is stable, and the service life of the upper furnace body made of castables is three times higher than that of the upper furnace body made of pure composite silicon ramming materials. times.

Embodiment 2

[0027] Composite silicon ramming material 14 has a thickness of 90cm and a height of 520cm at the position corresponding to the furnace mouth 16; a thickness of 70cm at the position corresponding to the core sensor installation opening 17, and a height of 550cm, and a thickness of 60cm at other positions. ㎝, the height is 750㎝;

[0028] The furnace volume of the holding furnace is 0.4 m³, the furnace volume of the melting furnace is 0.55 m³, and the furnace mouth slope is 3.5 。 , melting bottom slope 5 。 .

[0029] The unit power consumption of the billet in this embodiment is 420KW.h / t, the casting quality of the billet is stable, and the service life of the upper furnace body made of castable is three times higher than that of the upper furnace body made of pure composite silicon ramming material. times,

Embodiment 3

[0031] Composite silicon ramming material 14 has a thickness of 92cm and a height of 550cm at the position corresponding to the furnace mouth 16; a thickness of 73cm at the position corresponding to the core sensor installation opening 17, and a height of 520cm, and a thickness of 70cm at other positions. cm, the height is 730 cm;

[0032] The furnace volume of the holding furnace is 0.5 m³, the furnace volume of the melting furnace is 0.62 m³, and the furnace mouth slope is 4 。 , melting bottom slope 7 。 .

[0033] The unit power consumption of the billet in this embodiment is 422KW.h / t, the casting quality of the billet is stable, and the service life of the upper furnace body made of castable is three times higher than that of the upper furnace body made of pure composite silicon ramming material. times,

[0034] It is proved by experiments that the above-mentioned measures have been taken to achieve the expected purpose, and the unit power consumption with billet has dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com