Mixed injection optimization system for anti-riot water cannon vehicle

The technology of a water cannon and a mixing device is applied in the field of mixed injection optimization system for anti-riot water cannon vehicles, which can solve the problems of reducing the spray range of anti-riot water cannon vehicles, failing to play a dispersing effect, and reducing the dispersing range, and achieves enhanced deterrence, Simple structure and the effect of increasing the dispelling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

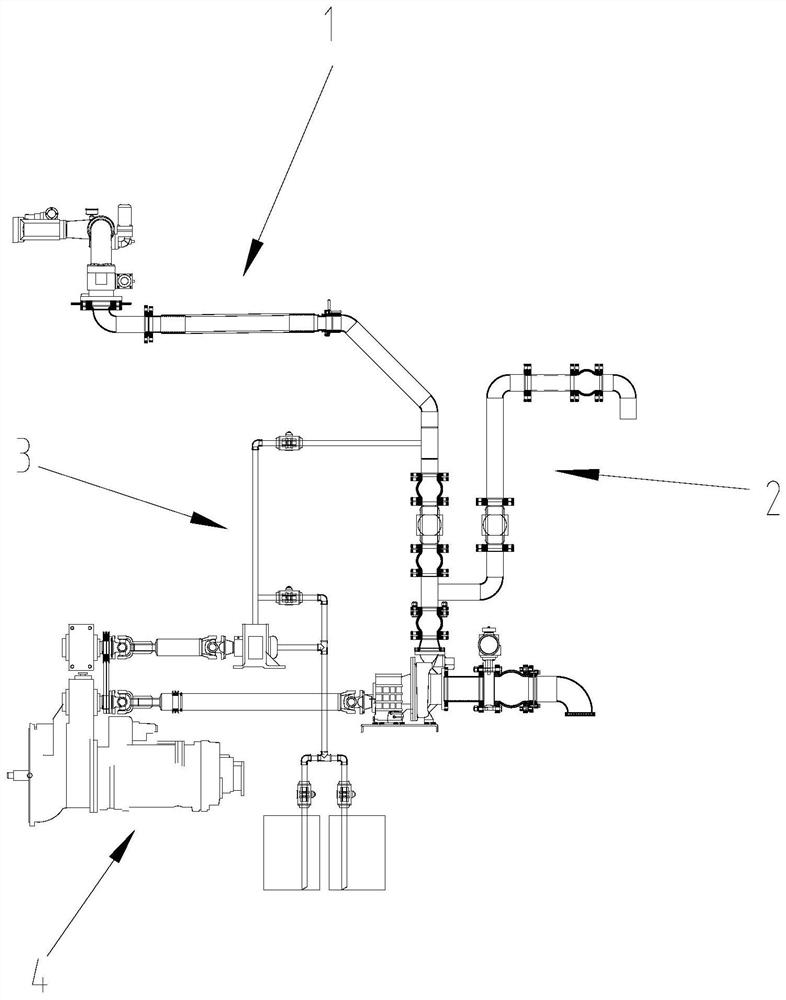

[0023] A mixed injection optimization system for anti-riot water cannon vehicles, such as figure 1 As shown, it includes a pulse water cannon mechanism 1, a pulse damping pipeline combination 2 connected to the pulse water cannon mechanism 1, and also includes a 2 communicated with a high-pressure injection mixing device 3, and a power unit 4 connecting the pulse damping pipeline assembly 2 and the high-pressure injection mixing device 3.

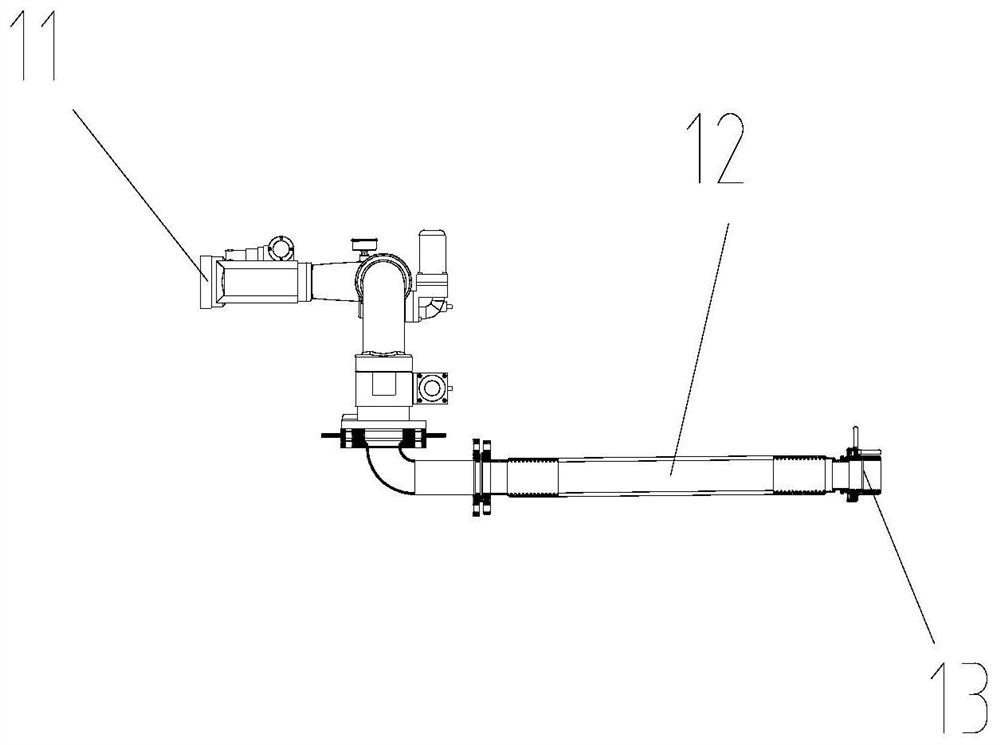

[0024] Such as figure 2 As shown, the pulse water cannon mechanism 1 includes a main water cannon 11, a hose 12 that is docked and fixed with the main water cannon 11, and a pulse shock absorber that is arranged at the end of the hose 12 for easy disassembly and assembly. Quick release coupling 13 for pipe set 2.

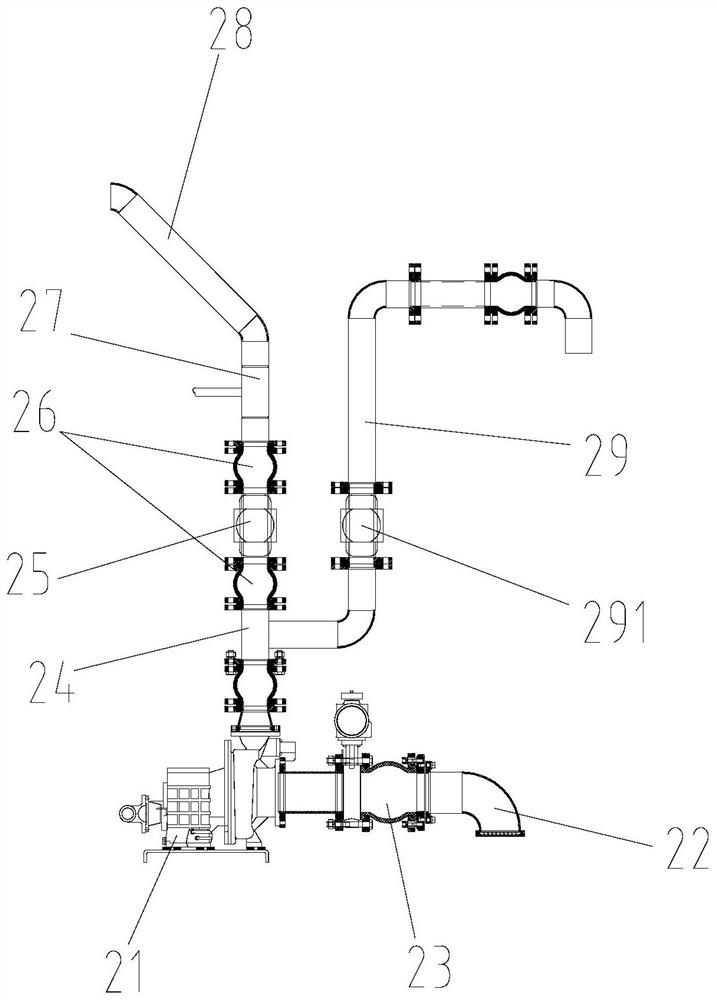

[0025] Such as image 3 As shown, the pulse damping pipeline assembly 2 includes a high-pressure water pump 21 connected to the main drive shaft 42, a suction pipe 22 connected at one end to the input end of the high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com