Air cylinder silencer

A muffler and cylinder technology, which is applied in the direction of instruments, sound-generating devices, fluid pressure actuators, etc., can solve the problems of long muffler pipeline, high cost, complex structure, etc., and achieve enhanced muffler effect, long service life and reduced noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

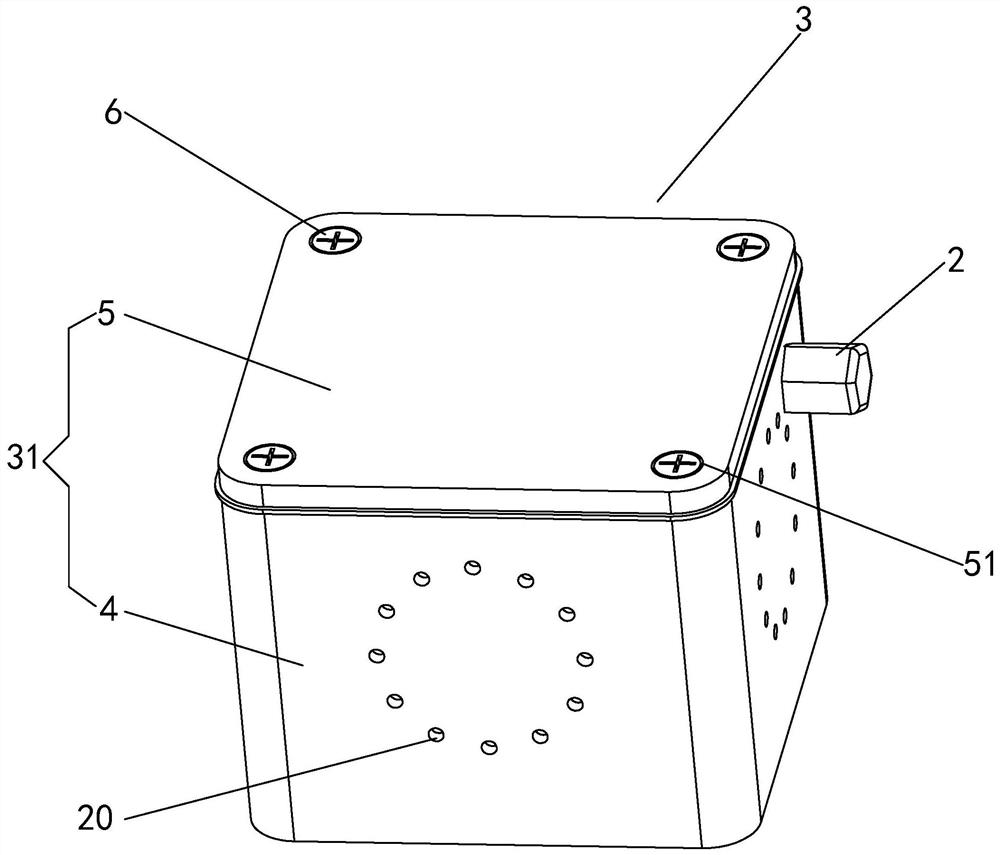

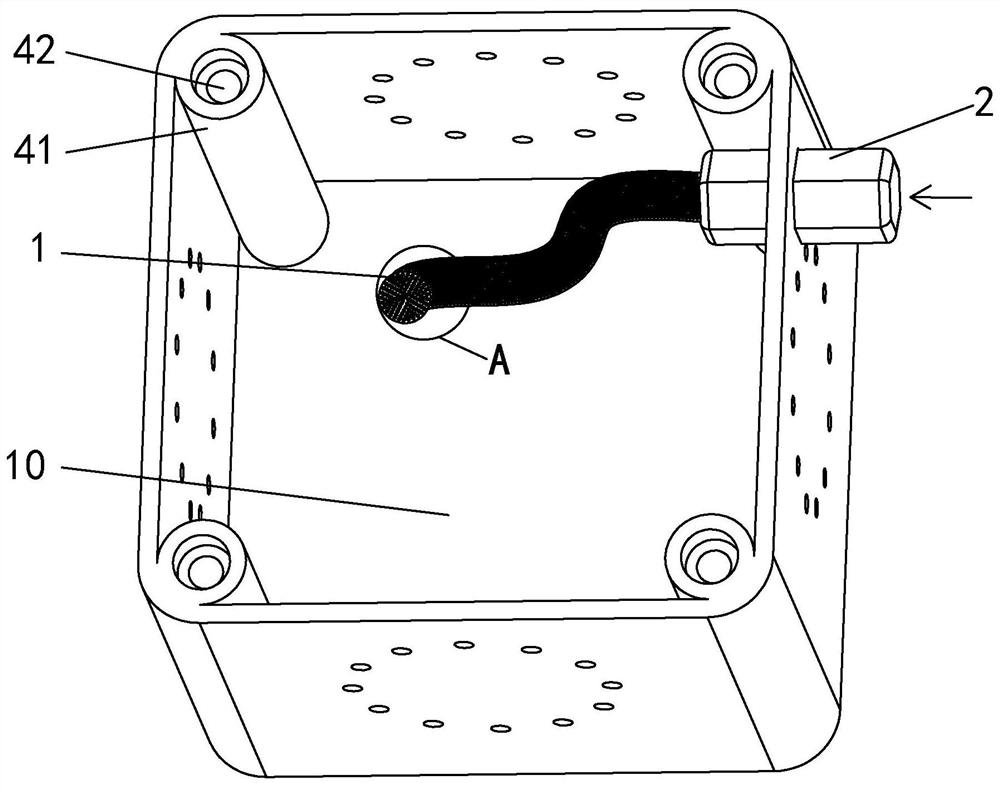

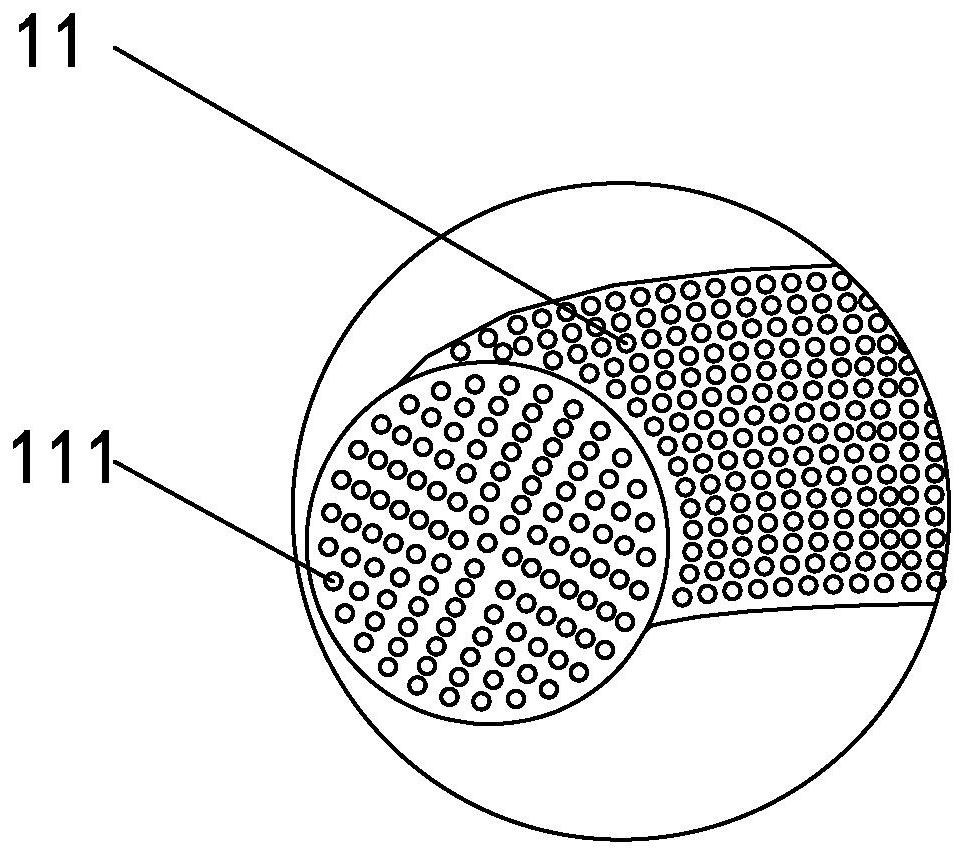

[0032] Embodiment 1: as Figure 1 to Figure 4 As shown, a cylinder muffler includes a muffler pipe 1 and a joint 2, and is characterized in that it also includes a muffler shell 3, the muffler shell 3 is fixed with a joint 2, and the muffler pipe 1 is placed in the muffler In the inner cavity 10 of the shell 3, the first end of the muffler pipe 1 is connected to the joint 2, and the other end of the joint 2 is an air inlet port 21 and extends out of the muffler shell 3. The muffler pipe 1 is a pipe made of elastic material , the pipe wall of the pipe body is provided with a plurality of pipe wall micropores 11, and the muffler shell 3 is also provided with an air outlet 20 communicating with the inner chamber 10; this type of cylinder muffler is provided with an elastic The silencer pipe 1 is made of high-quality materials, and the pipe wall of the silencer pipe 1 is provided with a plurality of pipe wall micropores 11. The waste compressed gas of the cylinder enters the silen...

Embodiment 2

[0037] Embodiment 2: as Figure 5 As shown, this embodiment is similar to Embodiment 1, and the difference is: the muffler shell is a tubular body 7 with the inner cavity 10; the working principle of this embodiment is similar to that of Embodiment 1, It will not be described in detail here.

[0038] like Image 6 As shown, it includes a combination of a plurality of cylinder mufflers, and it mainly connects the joints 2 of a plurality of cylinder mufflers through the air pipe 100 by adding an air pipe 100, so that a plurality of cylinder mufflers are connected in parallel; By connecting the cylinder mufflers in parallel to form a group of mufflers, on the one hand, the noise reduction effect is improved, and on the other hand, it can withstand greater air pressure and displacement to meet more user needs.

[0039] like Figure 7 As shown, it includes a combination of multiple cylinder mufflers, and each muffler shell 3 is provided with a rear interface 7, and the rear inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com