Hob cutter holder assembly suitable for large-scale shaft drilling machine drill bit

A hob and tool seat technology, which is applied in shaft equipment, sinking, earthwork drilling, etc., can solve problems such as the separation of the hob and the tool seat, the lack of a protective mechanism, and the gap between the hob cutter shaft and the tool seat, etc., to prevent Breaking away from the tool seat, improving the force on the tool shaft and the local stress concentration of the tool seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

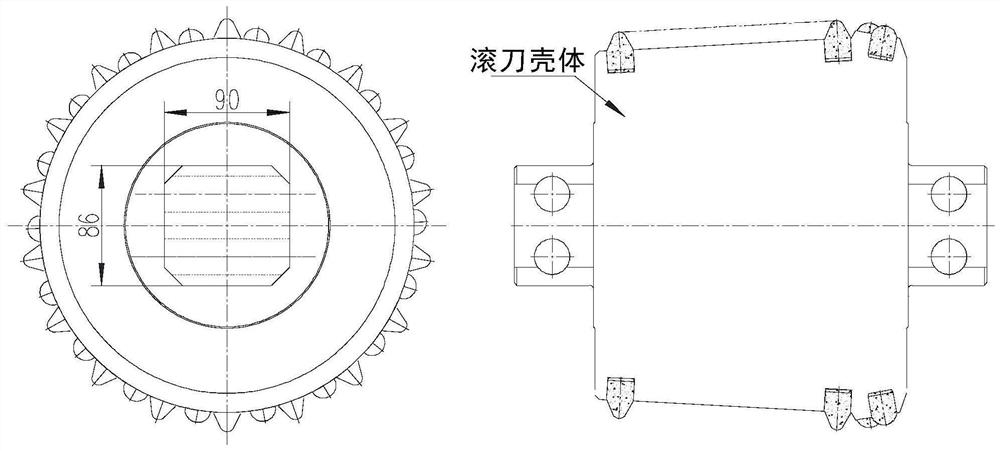

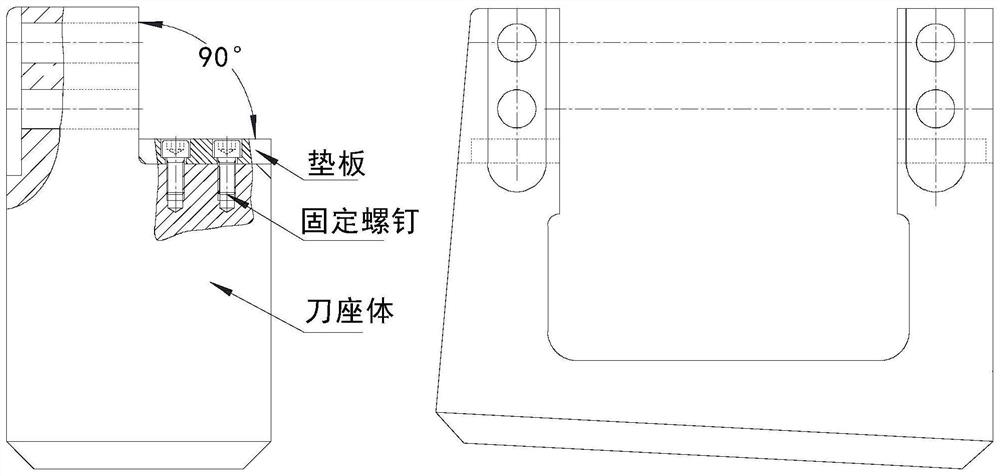

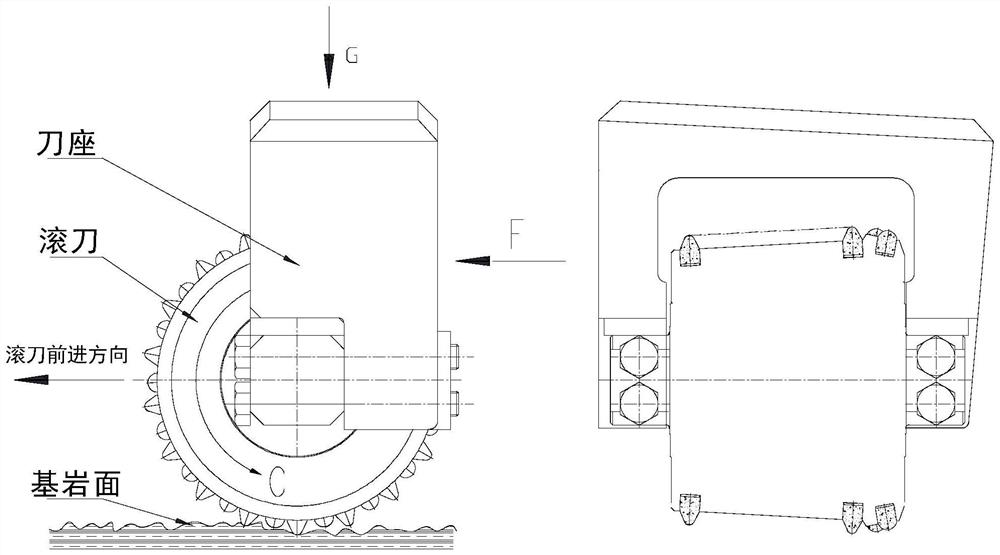

[0027] see Figure 4-7 : A hob tool holder assembly suitable for large shaft drilling rig bits, comprising a tool holder 1, a hob 2 and two hob preload bolts 3, the cutter holder 1 is provided with an opening, and the two ends of the opening are Obliquely upward pre-tightened threaded holes 101 are provided on the end surface of the wall, and both ends of the hob shaft of the tool seat 1 are respectively fixed in the pre-tightened threaded holes 101 by hob pre-tightened bolts 3 .

[0028] It should be noted that, in this embodiment, the combination surface of the tool seat and the hob shaft is changed from two sides to three sides and it is a tight fit, which is beneficial to improve the force on the tool shaft and the local stress concentration of the tool seat; the pre-tightening bolt of the hob shaft is set obliquely It can increase the vertical and horizontal movement of the hob shaft, which is beneficial to protect the bolts from being damaged.

[0029] In the specific i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com