APET film for UV offset printing

A technology of film and microencapsulated red phosphorus, which is applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of poor safety and non-flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

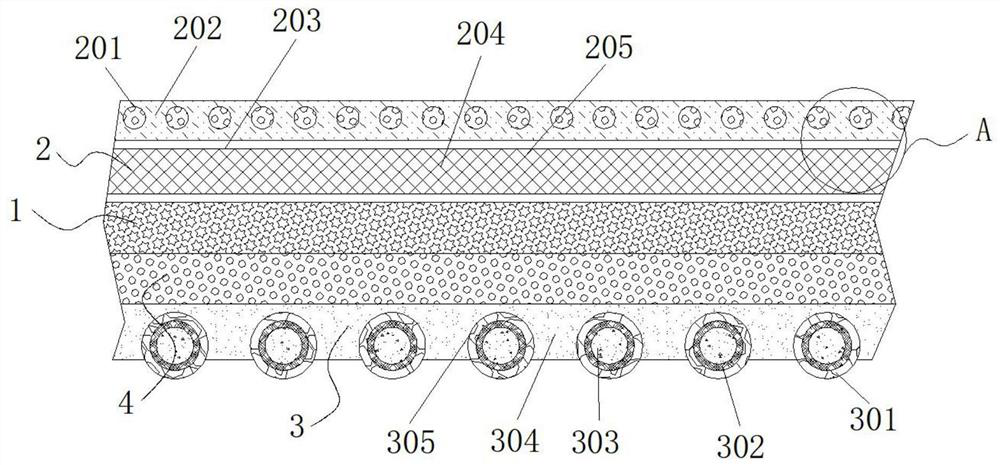

[0025] Example 1: See Figure 1-4 , an APET film for UV offset printing, comprising a substrate layer 1, an antistatic structure 2 is provided at the top of the substrate layer 1, an anti-slip structure 3 is provided at the bottom of the substrate layer 1, the substrate layer 1 and the anti-slip structure 3 is provided with a flame-retardant structure;

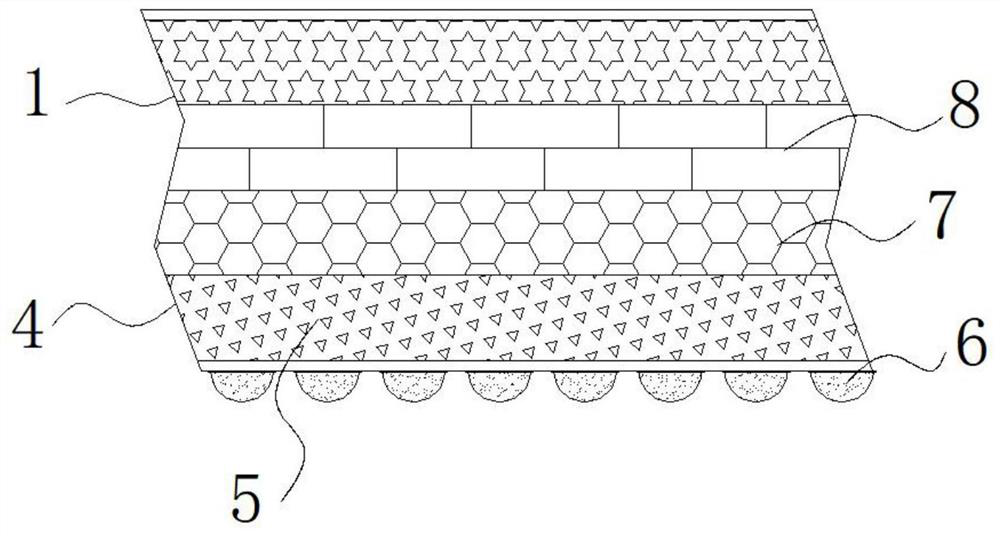

[0026] see Figure 1-4 , an APET film for UV offset printing also includes a flame retardant structure, the flame retardant structure includes a surface layer 4, the surface layer 4 is arranged on the bottom end of the base material layer 1, and the bottom end inside the surface layer 4 is fixedly connected with an anti-oxidation layer 5, the surface layer 4. A microencapsulated red phosphorus 8 is fixedly connected to the top inside, a thermal stabilizer 7 is fixedly connected between the anti-oxidation layer 5 and the microencapsulated red phosphorus 8, and a polycarbonate 6 is fixedly connected to the bottom of the surface...

Embodiment 2

[0029] Embodiment 2: Antistatic structure 2 is made up of fluorescent powder 201, fluorescent layer 202, antistatic layer 203, first fiber 204 and second fiber 205, and antistatic layer 203 is arranged on the top of substrate layer 1, and antistatic layer 203 One side of the interior is fixedly connected with the first fiber 204, and the other side of the antistatic layer 203 is fixedly connected with the second fiber 205. The top of the antistatic layer 203 is provided with a fluorescent layer 202, and the inside of the fluorescent layer 202 is provided with a fluorescent powder. 201;

[0030] Several groups of phosphor powders 201 are arranged, and the phosphor powders 201 are arranged at equal intervals inside the phosphor layer 202;

[0031] Specifically, such as figure 1 with Figure 4 As shown, the fluorescent powder 201 inside the fluorescent layer 202 can make the base material layer 1 have a unique fluorescent effect, so that the base material layer 1 can maintain a...

Embodiment 3

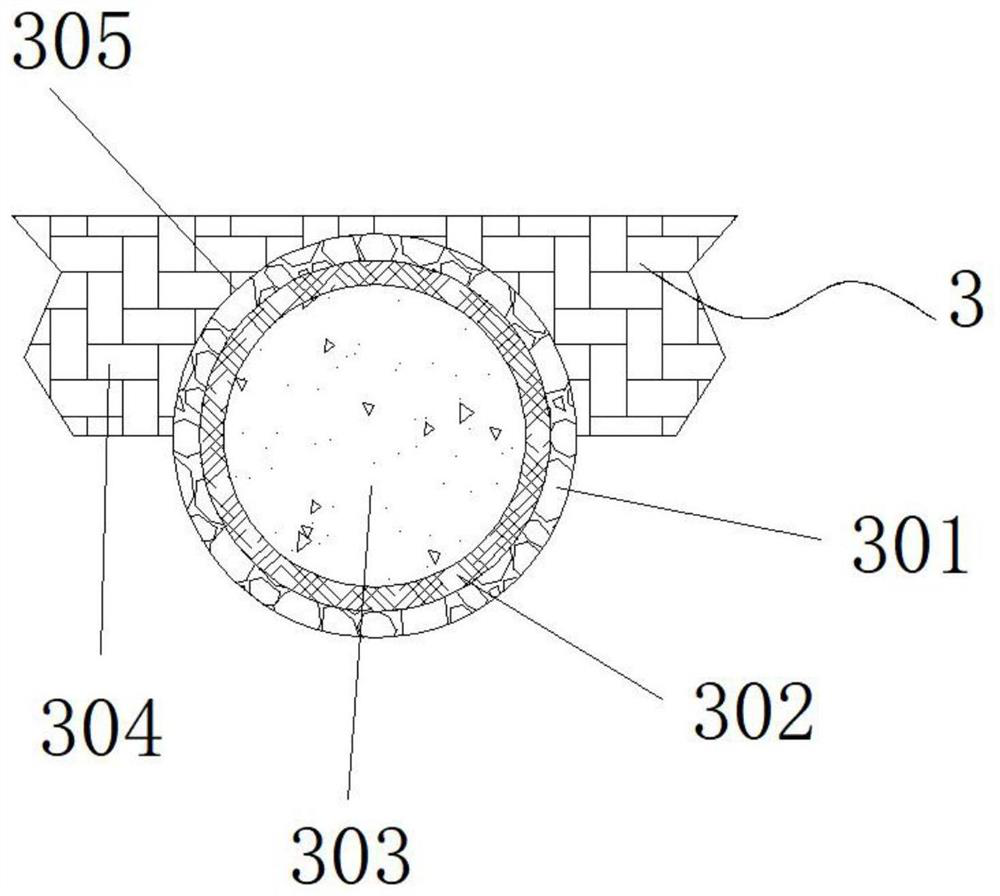

[0032] Embodiment 3: anti-slip structure 3 is made up of anti-slip layer 301, wear-resistant layer 302, glass microsphere 303, connection layer 304 and placement groove 305, and connection layer 304 is arranged on the bottom end of surface layer 4, and the bottom end inside connection layer 304 is arranged There is a placement groove 305, the interior of the placement groove 305 is provided with glass microspheres 303, the exterior of the glass microspheres 303 is fixedly connected with a wear-resistant layer 302, and the exterior of the wear-resistant layer 302 is provided with an anti-skid layer 301;

[0033] The glass microspheres 303 are arranged inside the placement groove 305, and the wear-resistant layer 302 is arranged between the glass microspheres 303 and the anti-skid layer 301;

[0034] Specifically, such as figure 1 with image 3 As shown, the surface of the substrate layer 1 is relatively smooth, so when the main body of the polypropylene film is used, the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com