Nomadic building prefabricated PC component production line and method

A production method and production line technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of prefabricated components that cannot be processed too large, bulky prefabricated components, cracking and disconnection of components, etc., and achieve favorable Green construction, convenient subsequent assembly, and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

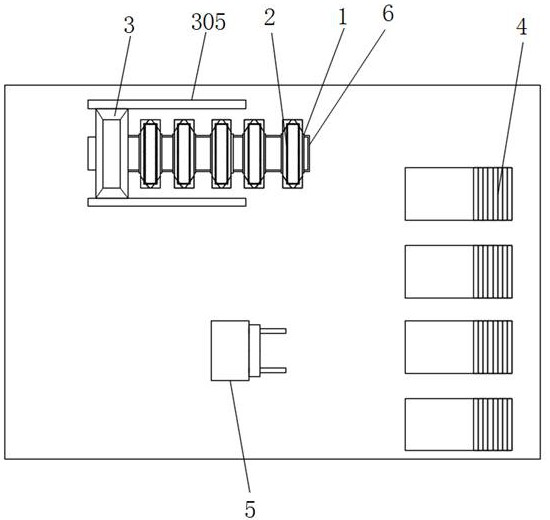

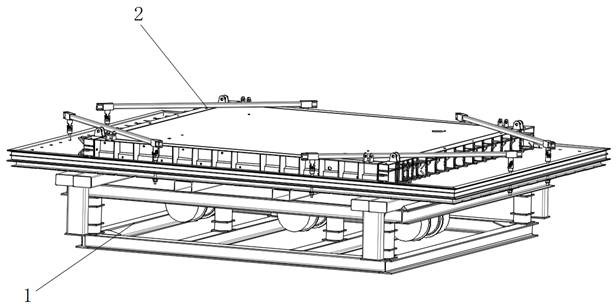

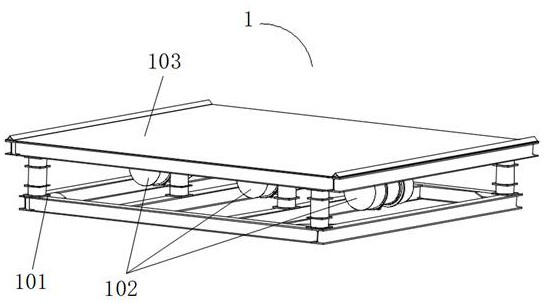

[0049] Such as Figure 1-Figure 14 As shown, a nomadic building prefabricated PC component production line is set on the construction site, including a cloth area and a steam curing area. The cloth area is tiled with a vibrating table 1 and a mold table assembly 2 arranged on the vibrating table 1. There is a material distributing device 3 above the mold table assembly 2; a plurality of foldable oxygen steaming rooms 4 are tiled in the steam curing area;

[0050] It also includes a transfer mechanism 5, which is used for the operation and stacking of the mold table components.

[0051] The transfer mechanism 5 is a mobile forklift.

[0052] There are more than one v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com