Three-soft coal seam gob-side roadway support method

A technology for roadway support and three-soft coal seam, which is applied in earth-moving drilling, mining equipment, bolt installation, etc., to achieve the effect of improving stability, good support effect and reducing weathering damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0021] A gob-side roadway support method in three soft coal seams:

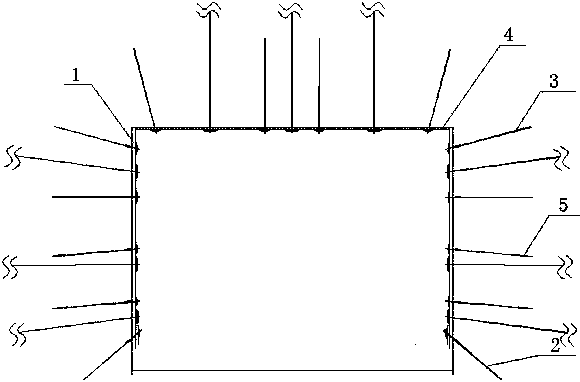

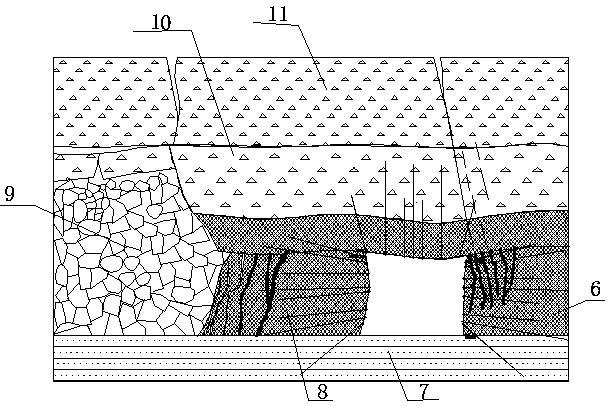

[0022] (1) Lay the metal mesh on the two sides 1 and the roof of the roadway, and install the steel belt 4, pass the anchor bolt with a length of 2.5~4m through the steel belt and anchor it in the surrounding rock, and the anchors near the roof on the two sides Rod 3 is raised by 10°~20°, the angle of bolt 2 at the bottom angle is 15°~45°, the rest of the bolts are perpendicular to the rock surface, and the breaking force of the bolts is greater than 180 kN; Layout, the row spacing is 600~1200mm, and the spacing between adjacent anchor rods in each row is 600~1000mm.

[0023] (2) After the roadway is excavated, first use resin to anchor the end of the anchor rod extending into the surrounding rock, and then pre-tighten the anchor rod. The pre-tightening f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking force | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com