Rigidity design method for double-rail six-sliding-block rolling guide rail pair

A rolling guide and stiffness design technology, applied in the field of machine tools, can solve problems such as low efficiency, repeated processes, and waste of rolling guide pair performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

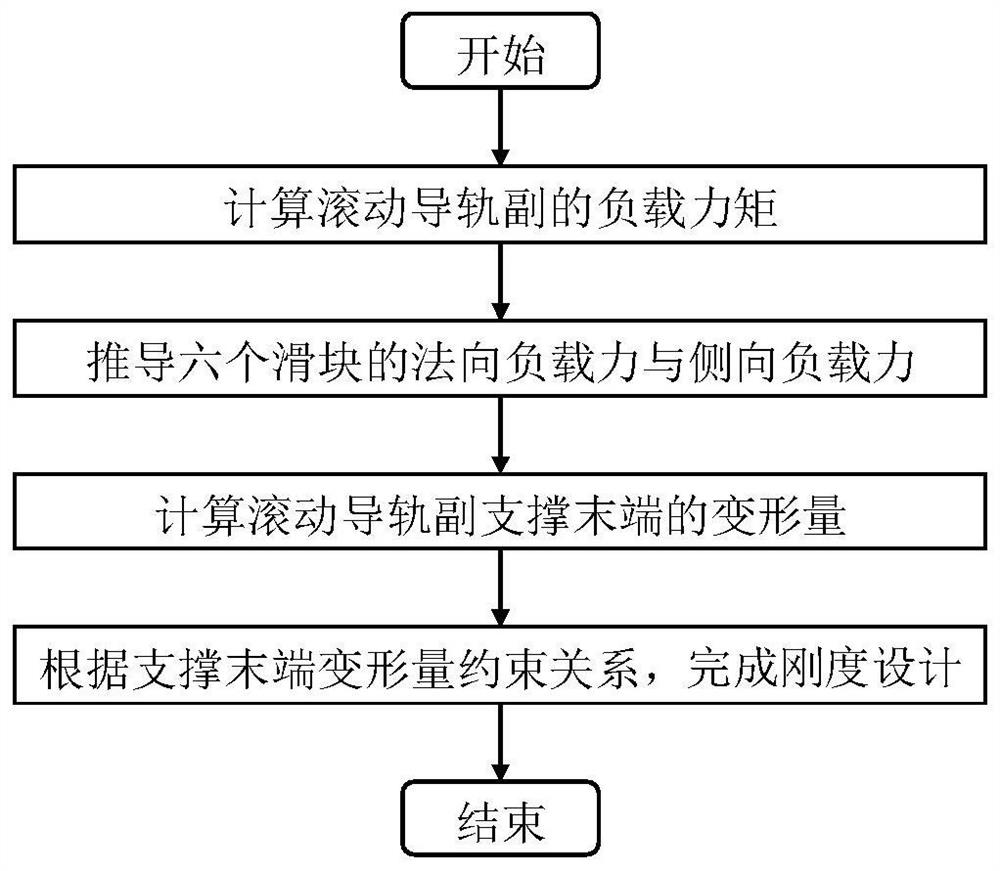

[0023] The stiffness design method for double-track six-slider rolling guide pair proposed by the present invention, its flow chart is as follows figure 1 shown, including the following steps:

[0024] (1) Calculate the load moment of the rolling guide pair as follows:

[0025]

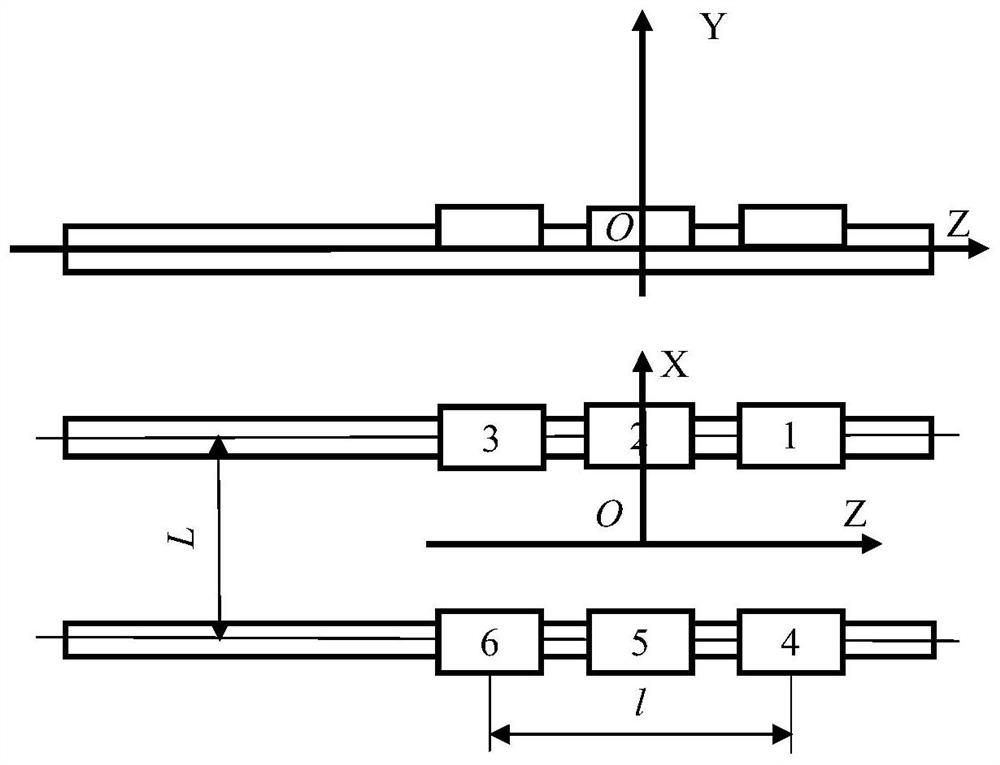

[0026] In the formula, M X , M Y and M Z are the load moment of the rolling guide rail in the direction of OX, OY and OZ in the Cartesian coordinate system O-XYZ, O is the origin of the coordinate system, F xk , F yk and F zk are respectively the kth force along the OX, OY and OZ directions that the rolling guide pair is subjected to, and the values of k are positive integers 1, 2, ..., x yk and z yk F respectively yk Coordinates along OX and OZ directions, x zk and y zk F respectively zk Coordinates along OX and OY directions, y xk and z xk F respectively xk Coordinates along the OY and OZ directions;

[0027] (2) Using the following formula, calculate the normal load force and la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com