Fluidization dust collector

A fluidized dust collector and dust collector technology, which is applied to chemical instruments and methods, instruments, sounding equipment, etc., can solve the problems of inconvenient cleaning, maintenance, and replacement operations, unsatisfactory gas dust removal effect, and large equipment volume, etc. Effective filter area, compact structure, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

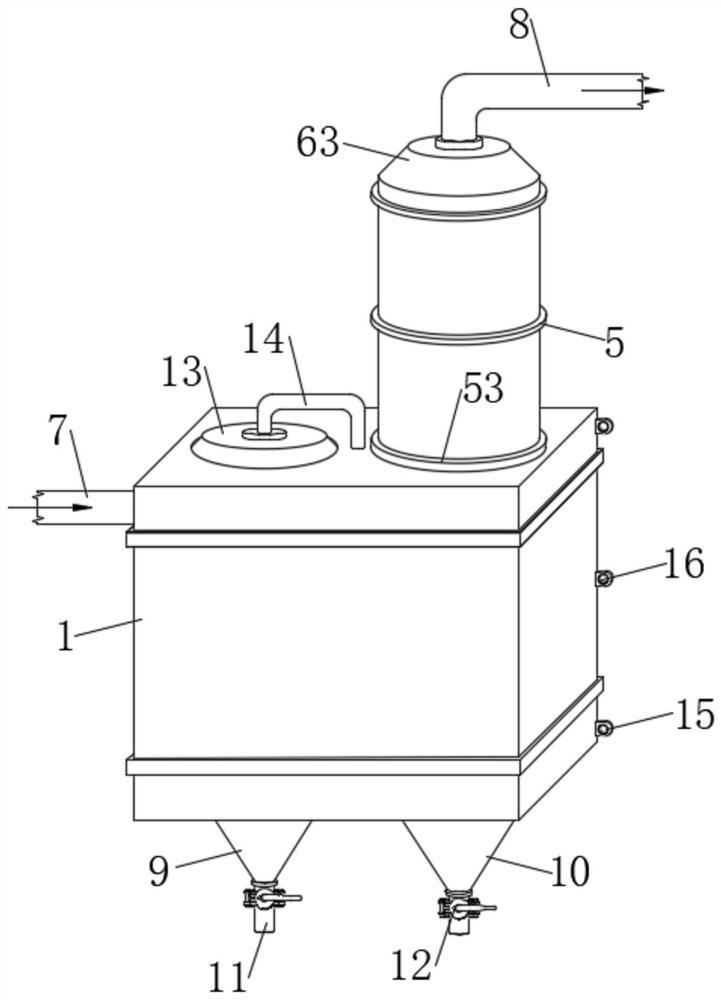

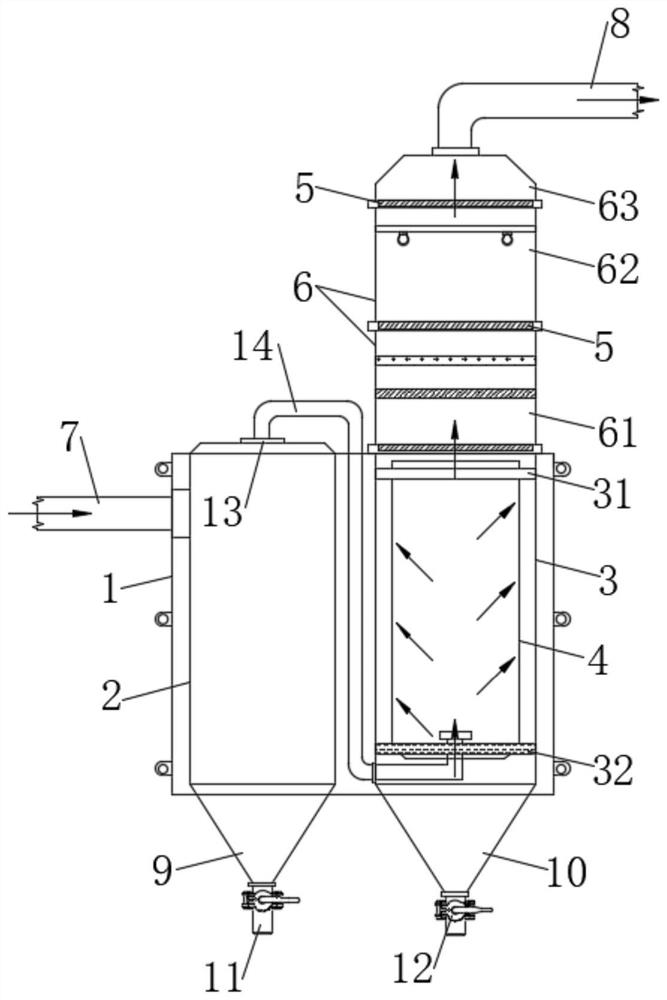

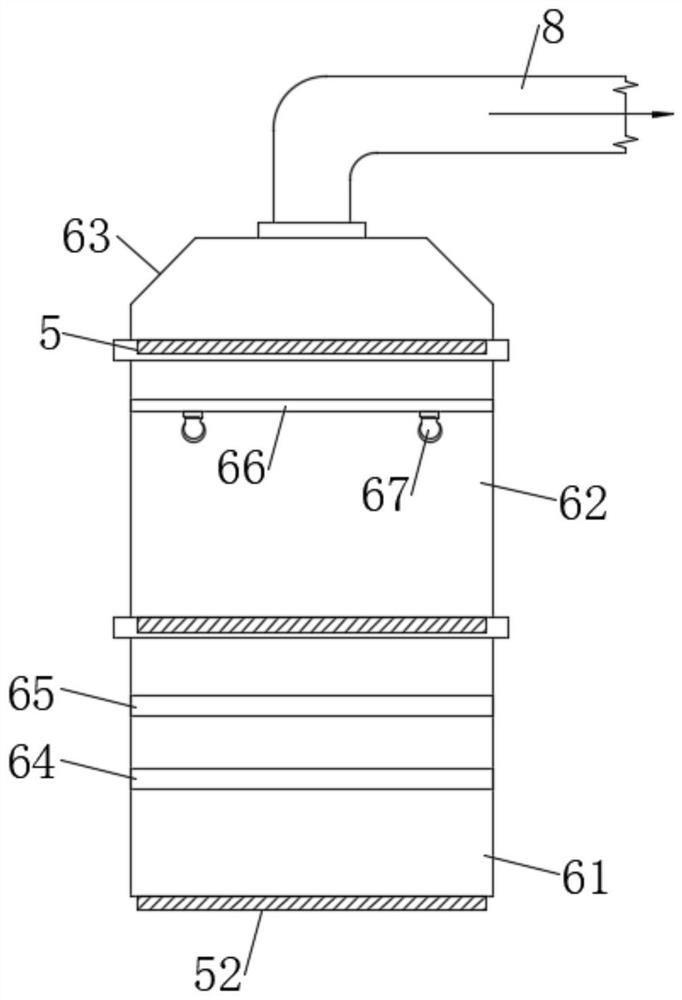

[0034] Example: such as Figure 1-7 As shown, a fluidized dust collector includes a dust removal box 1 and a cyclone dust collector 2, one side of the dust removal box 1 is fixedly installed with a cyclone dust collector 2, and the dust removal box 1 on one side of the cyclone dust collector 2 A filter bag dust collector 3 is fixedly installed, and a dust removal filter element 4 is fixedly installed inside the filter bag dust collector 3. The upper end of the dust removal filter element 4 is fixed with the filter bag dust collector 3 through a bracket 31, and the lower end of the dust removal filter element 4 The filter bag dust collector 3 is fixed through the carrier plate 32, and the splicing assembly 5 is fixedly installed on the dust removal box 1 at the top of the filter bag dust collector 3, and the top of the filter bag dust collector 3 is connected with the split type purifier through the splicing assembly 5 6 is fixedly installed, the upper end of one side of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com