A phosphate-based high-voltage flame-retardant electrolyte

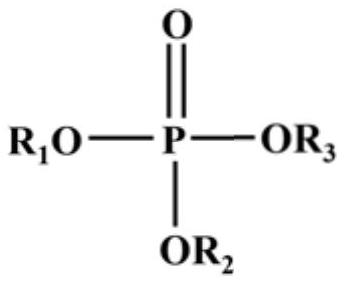

A phosphate-based, electrolyte technology, used in organic electrolytes, non-aqueous electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of poor wettability of electrode separators and high viscosity of phosphate esters, and achieve excellent cycle performance, low volatility, and easy The effect of large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

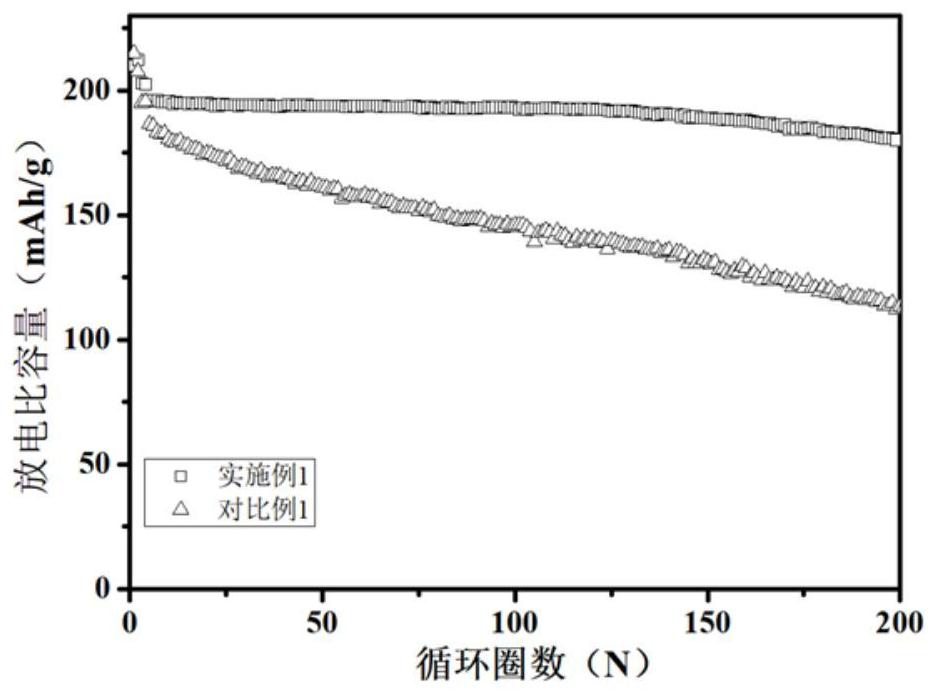

Embodiment 1

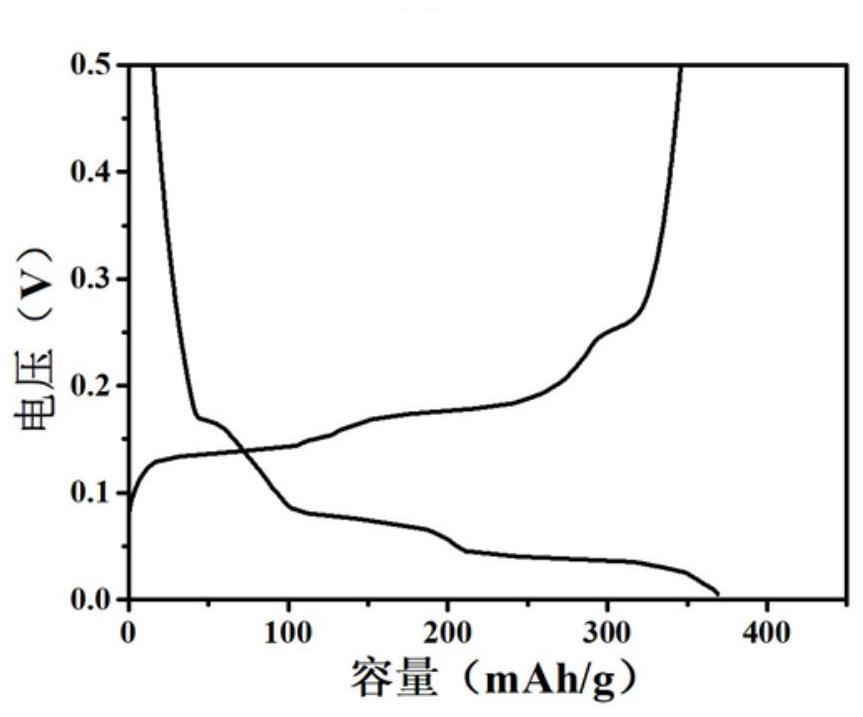

[0031] A phosphate-based high-pressure flame retardant electrolyte, the lithium salts are LiBOB and LiNO 3 , the solvent is trimethyl phosphate, and the diluent is 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether. The preparation method is as follows: trimethyl phosphate and LiBOB, LiNO 3 Weigh and mix according to the molar ratio of 8:1:0.1, stir evenly, and then add 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoroethyl 0.5 times the volume of trimethyl phosphate propyl ether. The electrolyte system was used in NCM 811||Li half-cell for physical properties and electrochemical cycle tests. The test found that the battery can cycle under 4.5V high voltage for 200 cycles and the capacity retention rate is greater than 90%; and the electrolyte is non-flammable of. At the same time, the compatibility of the electrolyte and the graphite negative electrode was also tested, and the 0.005-1.5V cycle test was carried out.

Embodiment 2

[0033] A phosphate-based high-pressure flame-retardant electrolyte, the lithium salt is LiFSI, LiPF 6 , the solvent is triethyl phosphate, and the diluent is bis(2,2,2-trifluoroethyl) ether. The preparation method is as follows: combining triethyl phosphate with LiFSI and LiPF 6 According to the molar ratio of 8:1:0.05, weigh and mix, stir evenly, and then add bis(2,2,2-trifluoroethyl) ether twice the volume of triethyl phosphate. The electrolyte system was used in NCM 811||Li half-cell for physical properties and electrochemical cycle tests. The test found that the battery can cycle under 4.5V high voltage for 200 cycles and the capacity retention rate is greater than 90%; and the electrolyte is non-flammable of. At the same time, the compatibility of the electrolyte and the graphite negative electrode was also tested, and the 0.005-1.5V cycle test was carried out.

Embodiment 3

[0035] A phosphate-based high-pressure flame-retardant electrolyte, the lithium salts are LiDFOB, LiBF 4 , the solvent is trioctyl phosphate, and the diluent is fluoromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether. The preparation method is as follows: combining trioctyl phosphate with LiDFOB and LiBF 4 According to the molar ratio of 8:1:1, weigh and mix, stir evenly, and then add the same volume of fluoromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether as trioctyl phosphate. The electrolyte system was used in NCM 811||Li half-cell for physical property and electrochemical cycle tests. The test found that the battery can cycle under 4.5V high voltage for 200 cycles and the capacity retention rate is greater than 80%; and the electrolyte is non-flammable of. At the same time, the compatibility of the electrolyte and the graphite negative electrode was also tested, and the 0.005-1.5V cycle test was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com