Fatigue test method for metal diaphragm of diaphragm compressor

A diaphragm compressor, fatigue testing technology, applied in the testing of mechanical components, testing of machine/structural components, vibration testing, etc., can solve the problems of high cost, inability to understand the performance of the diaphragm in advance, and long test cycle, and achieve direct results. The effect of testing, improving development efficiency and reliability, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

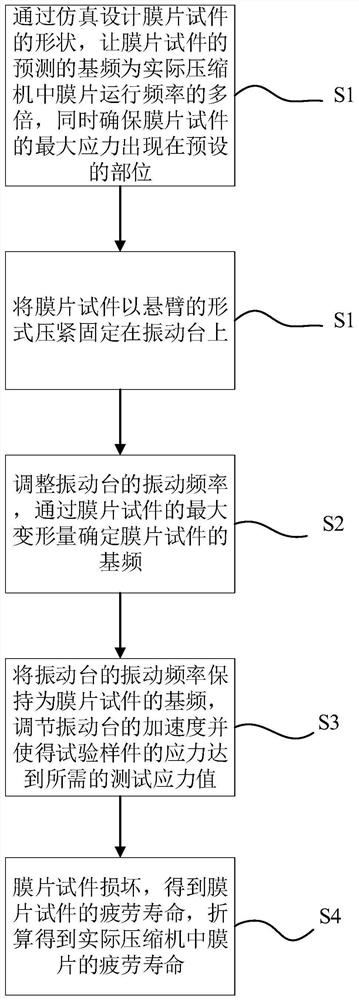

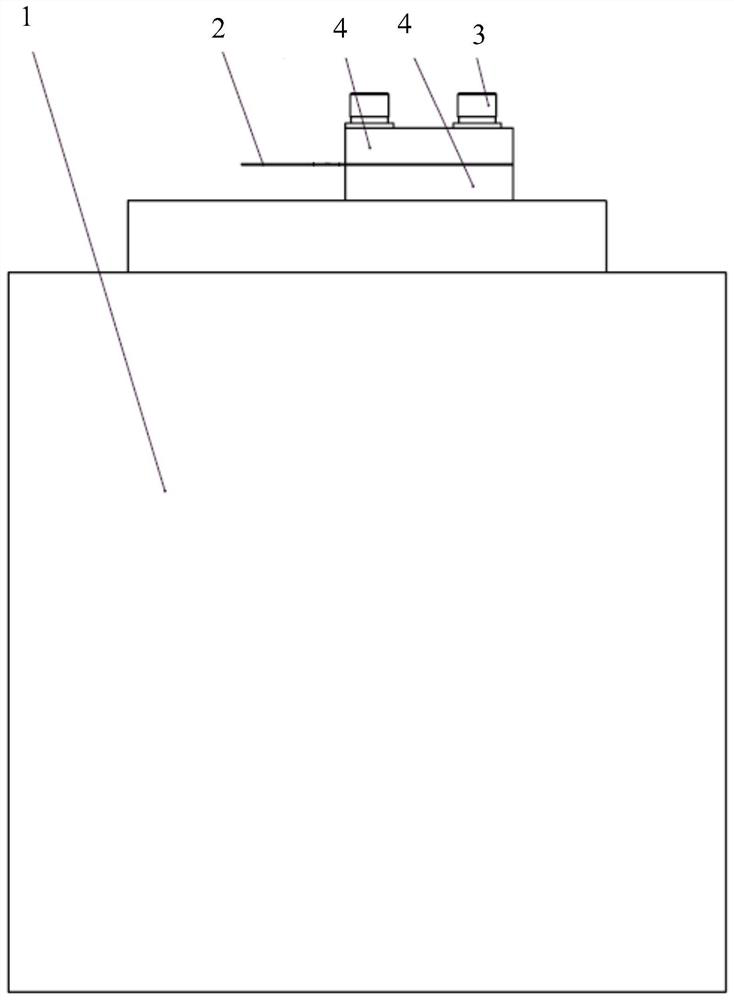

[0030] Such as Figure 1-Figure 4 As shown, this embodiment discloses a metal diaphragm fatigue test method for a diaphragm compressor, wherein the metal diaphragm fatigue test method for a diaphragm compressor includes the following steps:

[0031] Step S0, design the shape of the diaphragm test piece 2 through simulation, so that the predicted fundamental frequency of the diaphragm test piece 2 is multiple times the operating frequency of the diaphragm in the actual compressor, so as to shorten the fatigue test time and ensure that the diaphragm test piece The maximum stress of part 2 appears at the preset position;

[0032] Step S1, pressing and fixing the diaphragm test piece 2 on the vibrating table 1 in the form of a cantilever;

[0033] Step S2, adjusting the vibration frequency of the vibrating table 1, and determini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com