Right-angle pipe joint of hydraulic pipeline

A technology of right-angle pipe joints and hydraulic pipelines, which is applied in the direction of pipes/pipe joints/fittings, elbows, siphons, etc., which can solve the problems of many parts, affecting popularization and application, and large installation torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

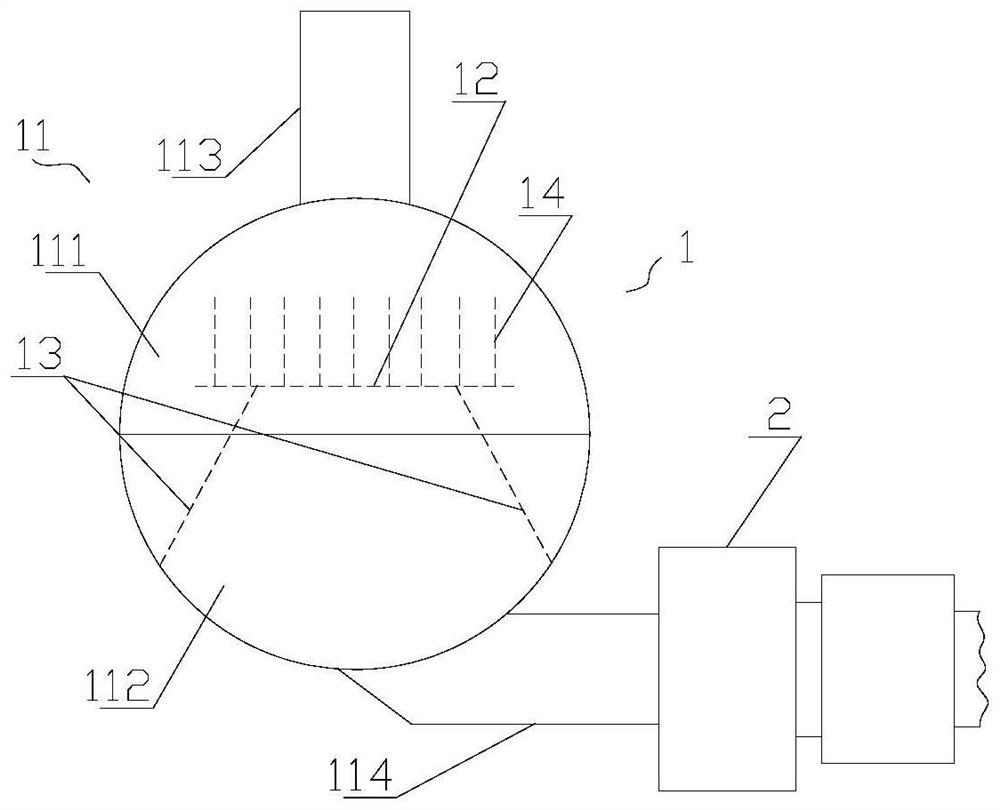

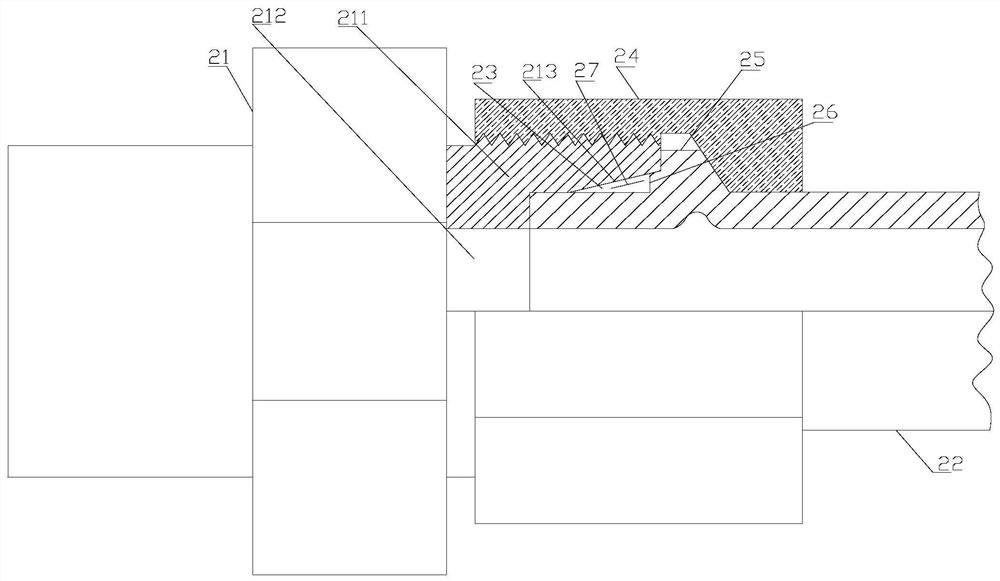

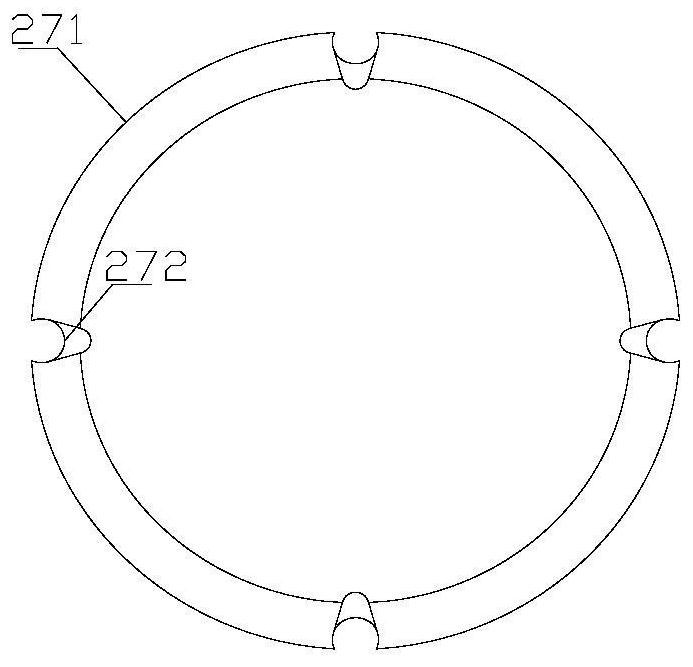

[0016] refer to figure 1 , figure 2 and image 3 , a hydraulic pipeline right-angle pipe joint in the present invention, comprising a right-angle joint body 1, the output end of the right-angle joint body 1 is provided with a pipe connector 2, and the pipe connector 2 includes a joint body 21, a pipe 22, a sealing ring 23 and a nut 24, the joint body 21 includes a connecting portion 211 with an external thread, the connecting portion 211 is provided with a stepped hole 212 with a small front and a large rear, and the rear end of the stepped hole 212 is a tapered hole 213 , the pipe end of the pipeline 22 is formed with an annular anti-off protrusion 25 through a cold forming process, and the pipeline 22 in front of the annular anti-off protrusion 25 is provided with a sealing ring 23 that matches the tapered hole 213, The pipe 22 behind the annular anti-off protrusion 25 is sleeved with a nut 24 threaded with the connecting portion 211, and the right-angle joint body 1 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com