Heat setting heating plate for pulp molding production equipment

A production equipment and pulp molding technology, which is applied in ohmic resistance heating, electric heating devices, textiles and papermaking, etc., can solve the problems of high risk, high energy consumption, and high energy consumption of electric heating tube heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

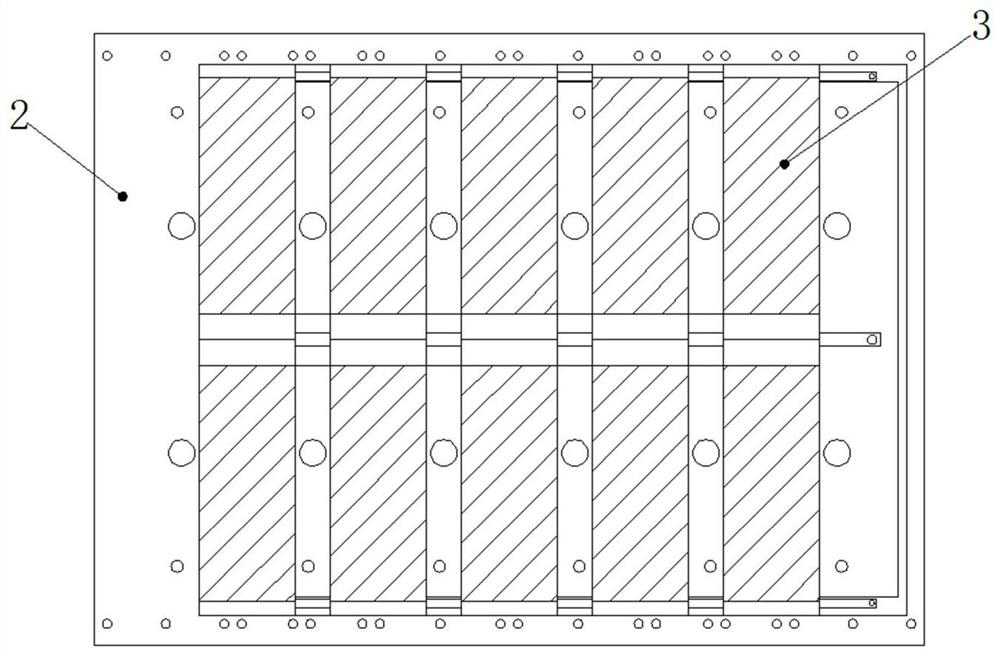

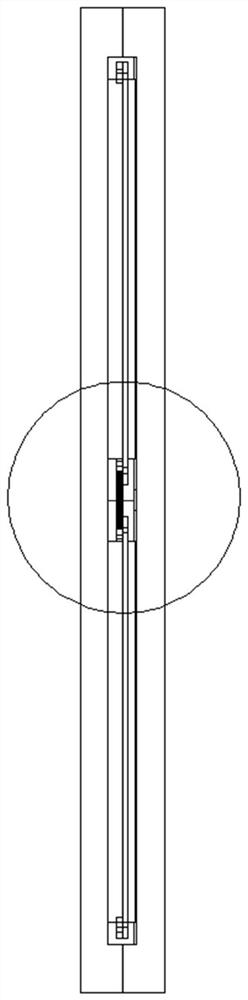

[0025] Such as Figure 1~4 Shown, a kind of heat-setting heating plate that is used for pulp molding production equipment includes metal heating plate and far-infrared nano glass-ceramic electric heater 3, and described heating plate comprises upper plate 1 and lower plate 2, in the A cavity 4 is formed between the upper plate 1 and the lower plate 2, and a far-infrared nano-glass ceramic heater 3 is provided; the positive and negative electrodes of the far-infrared nano glass-ceramic heater 3 extend outwards from the heating plate to be connected to electricity.

[0026] Such as figure 2 As shown, there are ten pieces of the far-infrared nano-glass-ceramics electric heater 3 (the heating surface of the whole far-infrared nano-glass-ceramic electric heater 3 is close to the surface size of the heating plate as much as possible on the basis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com