A kind of 400mpa grade disc screw steel and its preparation method and preparation device

A technology for preparing a device and a grading plate, which is applied in the field of 400 MPa-level plate screw steel, a preparation method and a preparation device, can solve the problems of increasing difficulty in performance stability control, inconvenient replacement of ladle, increasing unsafe factors, etc. Low stability, easy replacement, good performance in the same circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

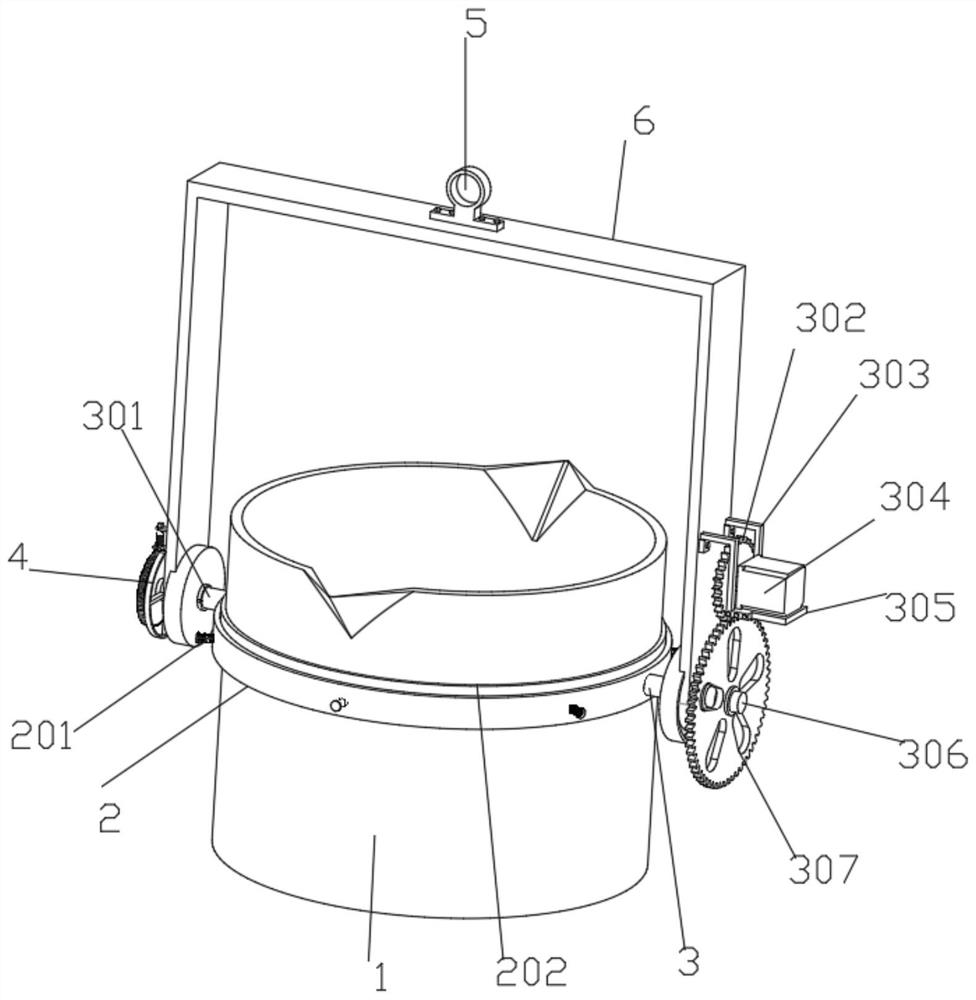

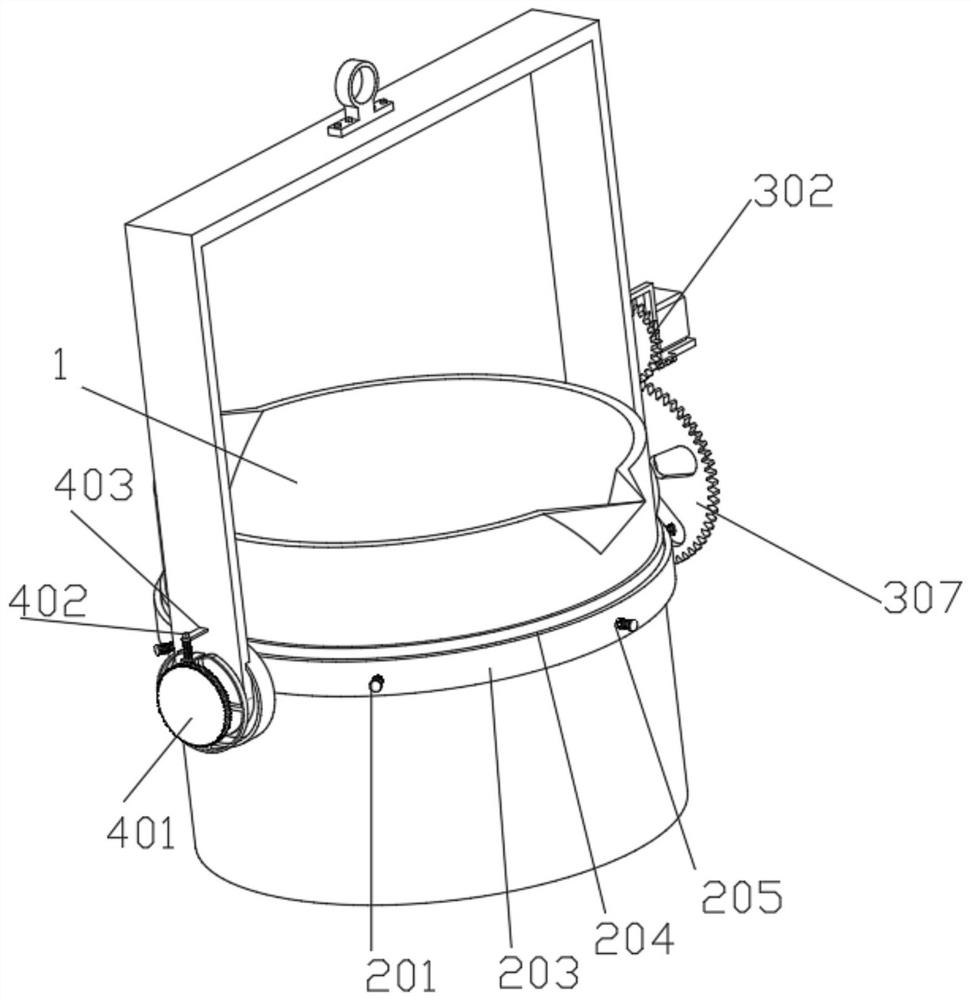

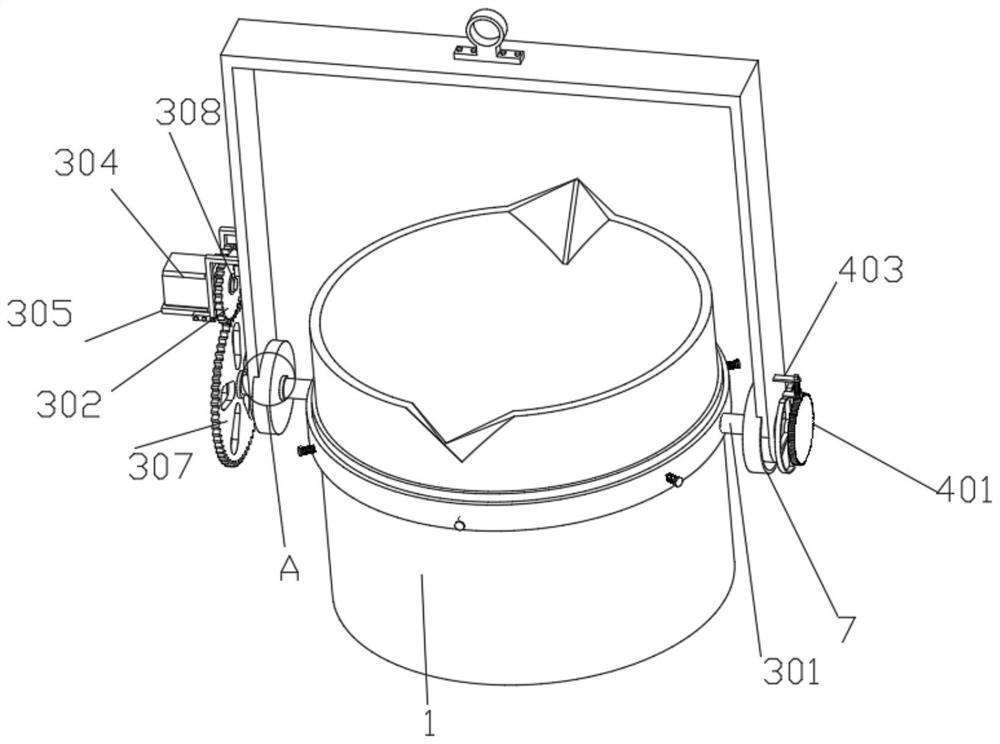

[0042] Such as figure 1 , 2 , 3, 4, 5, 8, 9, and 10 show a preparation device for 400MPa grade coil steel, including ladle 1, connecting ring 5 and the first n-shaped plate 6, the top of the first n-shaped plate 6 Fixedly connected with a connecting ring 5, the connecting ring 5 is connected with the external hoisting structure, the bottom of the first n-shaped plate 6 is connected with a rotating structure 3 for the rotation of the ladle 1, and the rotating structure 3 includes a first rotating rod 301, a first ring gear 302, the second n-shaped plate 303, drive motor 304, support plate 305, second rotating rod 306, second ring gear 307, rotating shaft 308, U-shaped sleeve 309 and fixing bolt 310, U-shaped sleeve 309 is welded on the first n At the side wall of the shaped plate 6, the second n-shaped plate 303 is plugged with the first ring gear 302, and the second n-shaped plate 303 and the U-shaped sleeve 309 are all screwed with fixing bolts 310 through the threaded holes...

Embodiment 2

[0045] Embodiment 2 is a further improvement to Embodiment 1.

[0046] Such as figure 1 , 2 , 3, 4, 6, and 7, the outer end of the first rotating rod 301 is connected with a locking structure 4 for locking the first rotating rod 301, and the locking structure 4 includes a rotating circular plate 401, a sliding rod 402, a second A fixed plate 403, the second spring 404, the fixed ring 405, the promotion ring 406, the concave plate 407, the movable block 408, the connecting rod 409, the movable tooth block 410 and the fixed tooth block 411, at the outer wall of the first rotating rod 301 Fixedly connected with a fixed ring 405 and a rotating circular plate 401, the rotating circular plate 401 is arranged on the outside of the fixed ring 405, the outer wall of the rotating circular plate 401 is evenly fixedly connected with a fixed tooth block 411 along the circumferential direction, and the outer wall of the fixed ring 405 is along the The circumferential direction is uniforml...

Embodiment 3

[0048] Embodiment 3 is a further improvement to Embodiment 1.

[0049] A 400MPa grade coil steel, the mass percentage of its components is: C 0.16-0.23%, Si 0.28-0.43%, Mn 0.60-1.30%, P≤0.055, S≤0.065, Wu0.23-0.46%, N 0.036~0.052%, Cr ≤0.25%, Mo≤0.15%, Cs≤0.15%, Cu≤0.15%, the rest is Fe and unavoidable impurities, it is difficult to control the performance stability of the coil steel, and the performance It is of great practical significance to improve economic benefits and reduce environmental pressure.

[0050] During use, a kind of preparation method of the preparation device of 400MPa level disc spiral steel, preparation method is as follows:

[0051] Step 1, the ladle 1 moves downward, the ladle 1 pushes the trapezoidal block 207 to move into the horizontal groove 208, then the ladle 1 drives the mounting ring 202 to be inserted into the slot 204 of the support ring 203, the bottom of the mounting ring 202 is in contact with the insert The bottom of the groove 204 conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com