Robot automatic stacking intelligent warehouse and working method thereof

A technology of automatic stacking and working methods, applied in the field of intelligent warehousing, can solve the problems of mutual influence of machine operation, decrease of warehouse volume, messy storage location of goods, etc., and achieve the effect of improving warehousing operation ability, improving computing ability, and facilitating overall management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

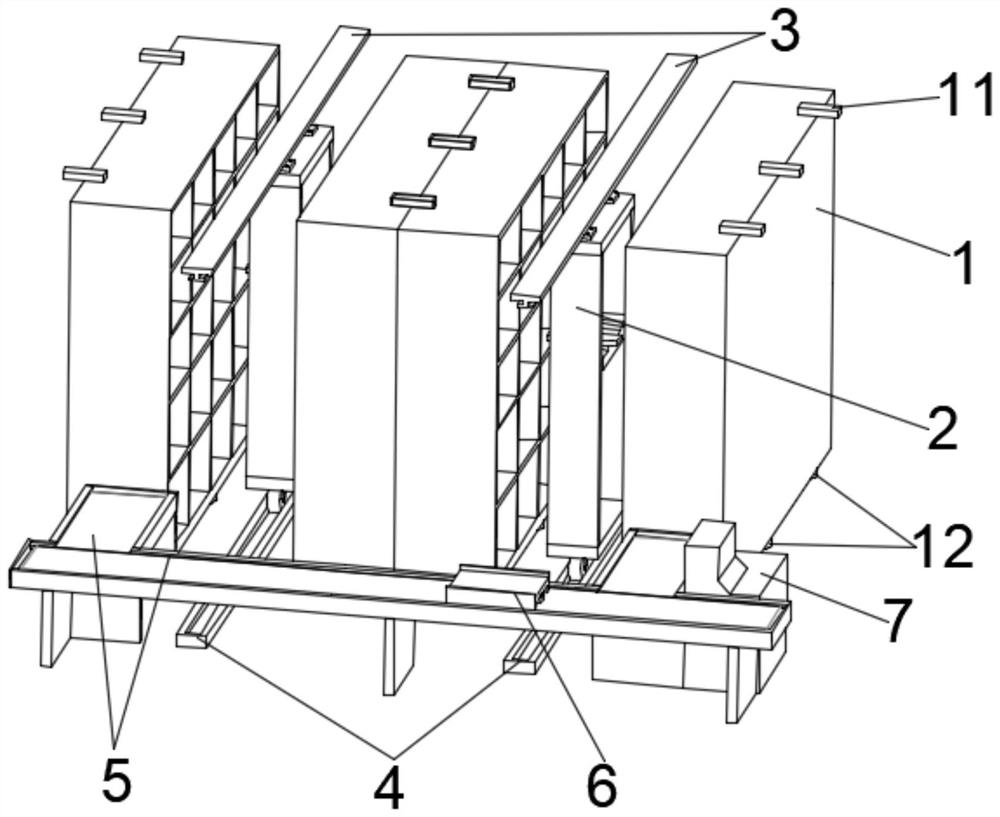

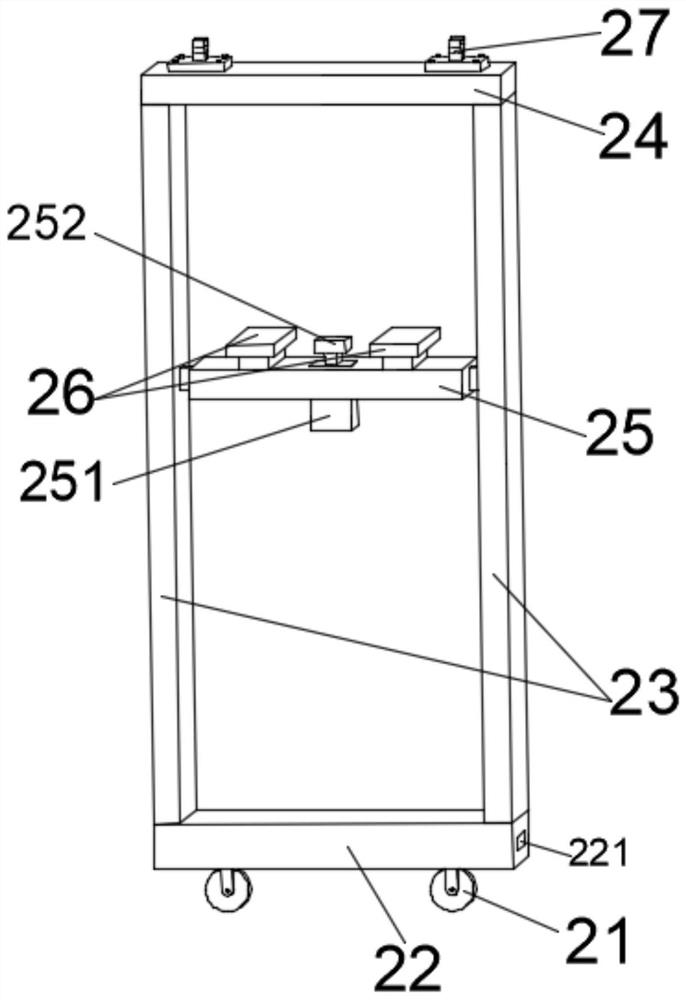

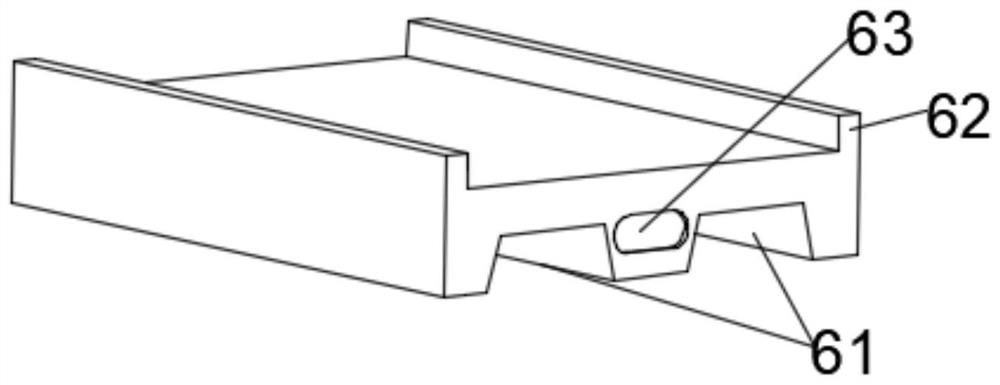

[0025] combine Figure 1-Figure 3 The robot automatic stacking intelligent warehouse shown includes several rows of shelves 1 installed in the warehouse, stackers 2 between the lanes of the shelves 1, conveyor lines 5 beside the shelves 1, pallets 6 and a master control machine 7. The running track of the stacker 2 is provided with a sky rail 3 and a ground rail 4, and the sky rail 3 and the ground rail 4 are respectively fixed on the ceiling and the ground. The stacker 2 includes a mounting base 22, a guide rail 23, a top beam 24 and cargo platform 25, two sets of guide rails 23 are arranged longitudinally between the mounting base 22 and the top beam 24, and the cargo platform 25 can be lifted and lowered along the guide rails 23, and a set of telescopic Fork 26, a group of wheels 21 are provided at the bottom of the mounting seat 22, a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com