System and method for removing dioxin from fly ash

A dioxin removal technology, which is applied in separation methods, chemical instruments and methods, and solid waste removal, etc., can solve the problems of incineration fly ash disposal cost constraints, and the difficulty of popularization and application of the technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

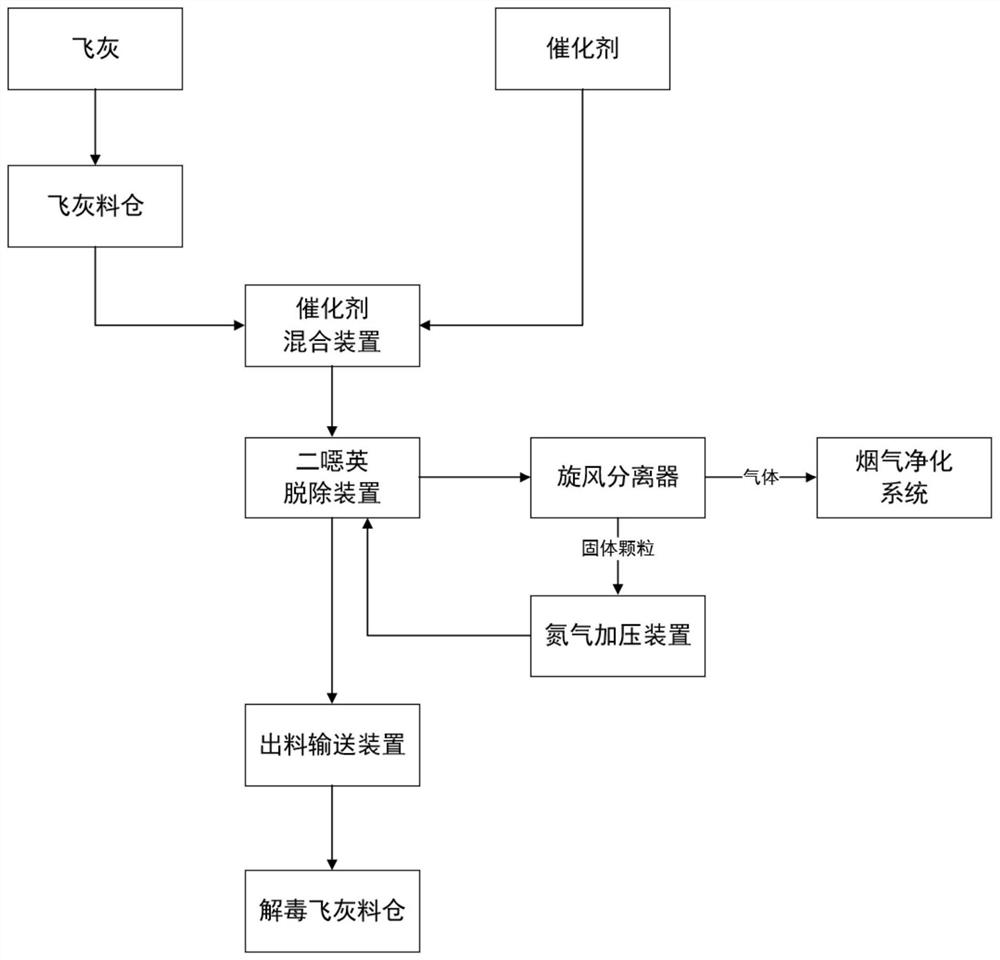

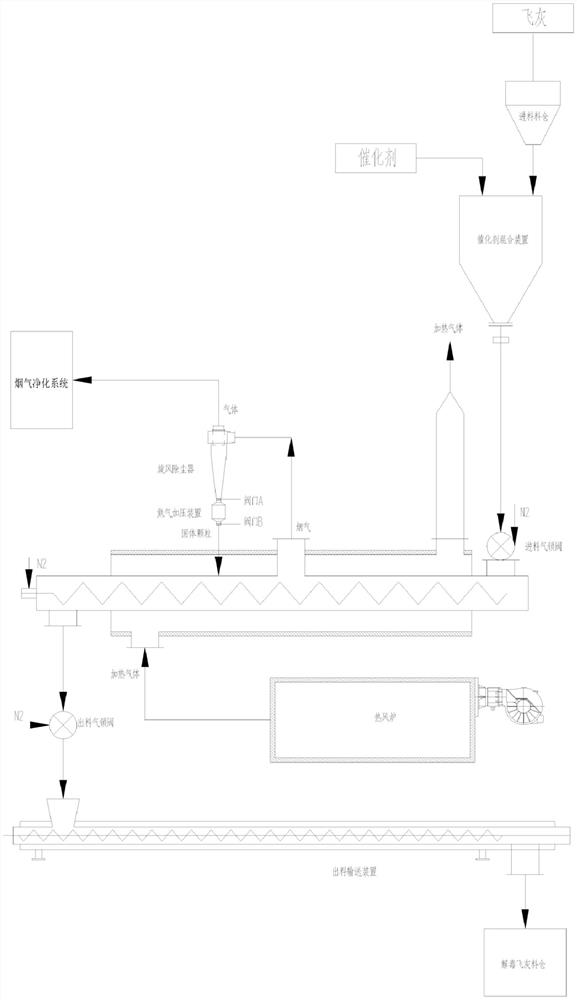

[0041]A flying ash removes the dioxin system, such asFigure 1-2As shown, including the sequentially connected fly ash silicon, dioxin removal device, discharge delivery device, and detoxification flyer bin, further comprising a catalyst mixing apparatus, the catalyst mixing device is disposed in a fly ash bin and two There is a CA-containing compound and a transition metal oxide in the catalyst added in the catalyst mixing apparatus, and in particular, the catalyst comprising a desulfurized lime powder CaO, Ca (OH) 2 and CaCO3 As a Ca-containing compound, MgO, manganese dioxide, and silica are contained as a transition metal oxide. Preferably, Na2CO3, sodium citrate is further included. Under low temperature heat treatment decologic conditions, it is not possible to provide a lower chance of reacting with hydroxy radicals and high energy, hydroxylation, and benzene crackers. Dichloro / Hydrogenation is considered to be the main pathway of dioxin removal over a period of time. By set...

Embodiment 2

[0060]A fly ash removes the dioxide system, replacing the catalyst mixing apparatus in Example 1, such asFigure 1-2As shown, the catalyst mixing device is a liquid spray mixing device. The catalytic solvent can be better mixed with fly ash, which makes the reaction more sufficient and more efficient.

[0061]Correspondingly, this example also discloses a fly ash removal dioxide method, including the following steps:

[0062]A. Insert nitrogen into the dioxinum removal device, and form an oxygen in the dioxin removal device;

[0063]B. In the fly ash fly ash stored in the fly, fly, fly as average, and the catalyst is sufficiently mixed with the catalyst to obtain a fly ash mixture, and the dioxin removal device is given by the feed gas lock valve;

[0064]C. In the dioxin removal device, the fly ash mixture is heated to 450 ° C by external heat insulating heating, and the reaction time is 15 min, and the dioxin is removed.

[0065]D. Tixin fly as average enters the discharge screw conveyor by the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com