Liquid crystal screen heat dissipation structure of projection ray machine

A heat-dissipating structure and technology for a projector, applied in the field of projectors, can solve problems such as the decline of the optical performance of the optical components of the projector and the reduction of the service life of the projector, and achieve the effect of improving the service life and improving the heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

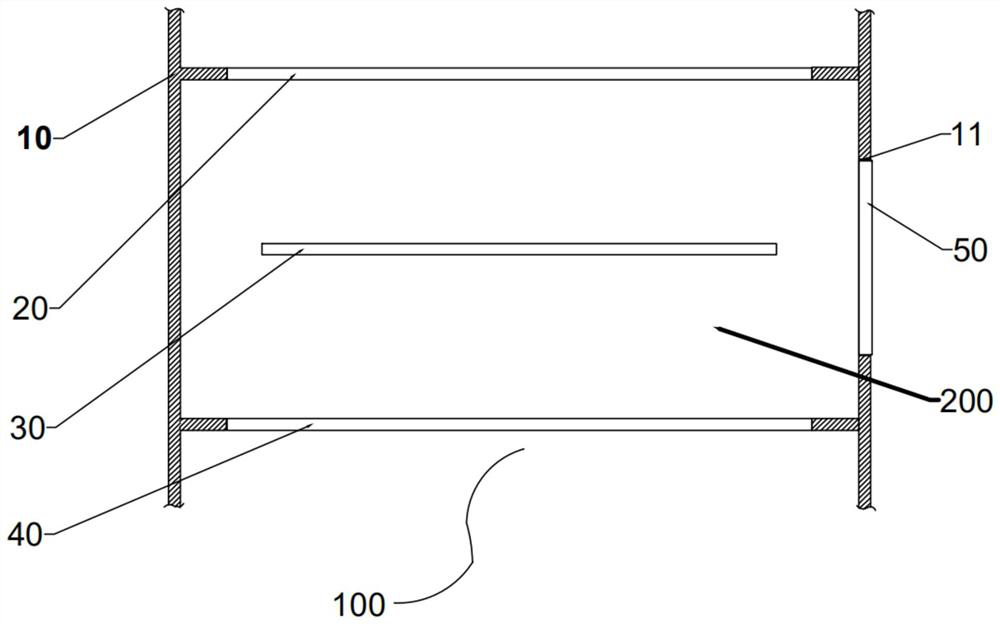

[0024] Such as figure 1 As shown, the embodiment of the present invention provides a heat dissipation structure 100 for a projection optical machine liquid crystal screen, which includes a casing 10, in which a first lens 20, a liquid crystal screen 30, and a second lens 40 are sequentially arranged along the optical path. The space between the first lens 20 and the second lens 40 forms a sealed cavity 200 through the casing 10, and an opening 11 is provided on the wall of the casing 10 in the cavity 200, and a semiconductive cooling chip 50 is arranged at the opening 11 and the The opening 11 is sealed, the cooling surface of the semiconductor cooling chip 50 faces into the cavity 200 , and the heating surface of the semiconductor cooling chip 50 faces outside the casing 10 .

[0025] In the embodiment of the present invention, by accommodating the liquid crystal screen 30 in the cavity 200 which is sealed by the first lens 20, the second lens 40 and the casing 10, an opening...

Embodiment 2

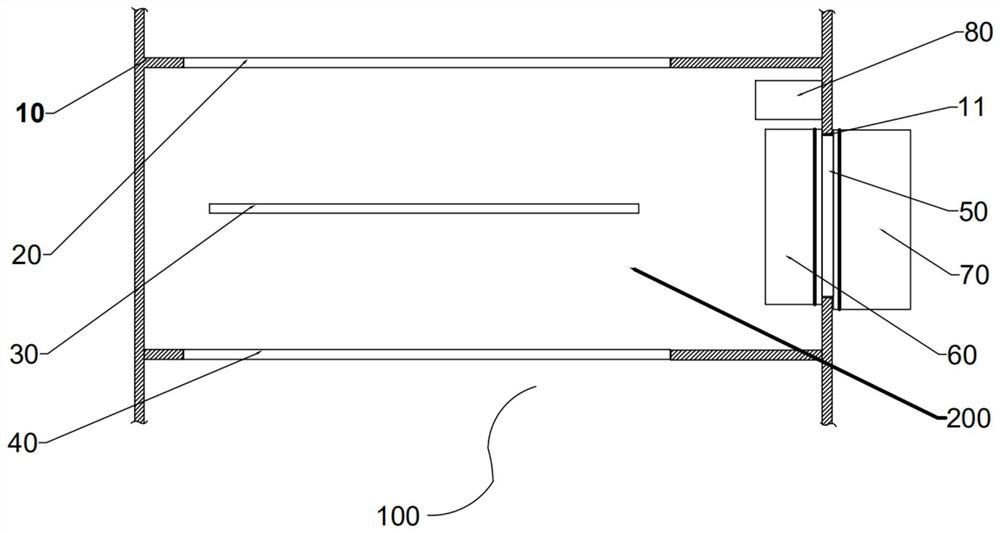

[0027] Such as figure 2 and image 3 As shown, the embodiment of the present invention proposes a new technical solution based on the first embodiment to further improve the cooling efficiency of the cavity in the sealed cavity. The embodiment of the present invention also includes an internal A radiator 60 , the inner radiator 60 is attached to the cooling surface of the semiconductor cooling sheet 50 . In the embodiment of the present invention, by increasing the inner radiator 60, the contact area between the cooling surface and the air in the sealed cavity 200 is increased, thereby improving the cooling efficiency.

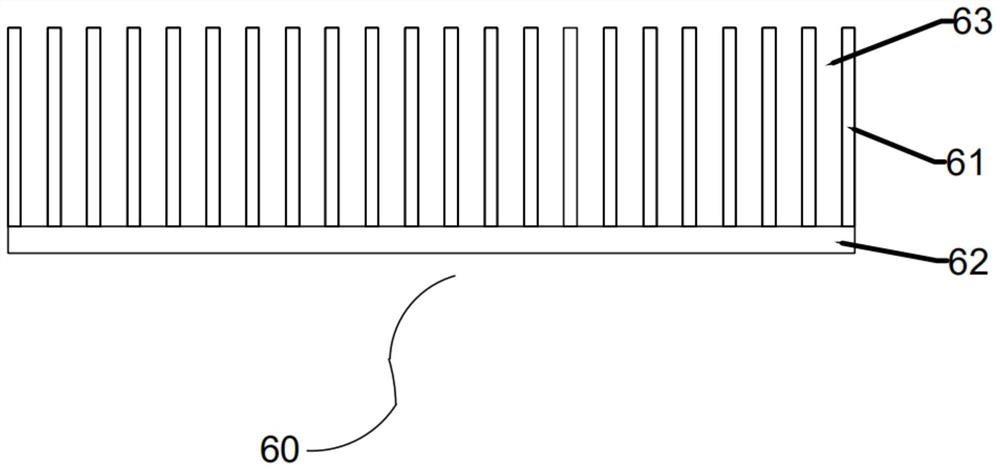

[0028] In the embodiment of the present invention, the preferred structure of the inner radiator 60 includes a plurality of heat sinks 61 and a heat dissipation base 62. One end of the plurality of heat sinks 61 is mounted side by side on the heat dissipation base 62, and a heat dissipation structure is formed between the plurality of heat sinks 61. channel...

Embodiment 3

[0032] Such as Figure 4 As shown, the implementation of the present invention is a further improvement to Embodiment 2. A first ventilation channel 201 is formed between the liquid crystal screen 30 and the first lens 20, and a ventilation channel 201 is formed between the liquid crystal screen 30 and the second lens 40. A second ventilation channel 202 is formed, the first ventilation channel 201 and the second ventilation channel 202 form a circulation air path through the third ventilation channel 203 and the fourth ventilation channel 204, and the heat dissipation channel 63 of the inner radiator 60 and the circulating air The fan 80 is installed on the fourth ventilation passage 204 and circulates the air along the circulation air passage.

[0033] In the embodiment of the present invention, cooling air is circulated around the liquid crystal screen 30 to dissipate heat from the liquid crystal screen 30 .

[0034] In the embodiment of the present invention, in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com