Integrated two-way transmission oil-gas multiphase pump

An oil-gas mixed pump and two-way transmission technology, which is applied in the direction of non-variable pumps, pumps, machines/engines, etc., can solve the problem of large volume of motor peripheral pump body, large vibration and noise, long axial length of mixed pump, etc. problem, to achieve the effect of improving efficiency, reducing noise and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

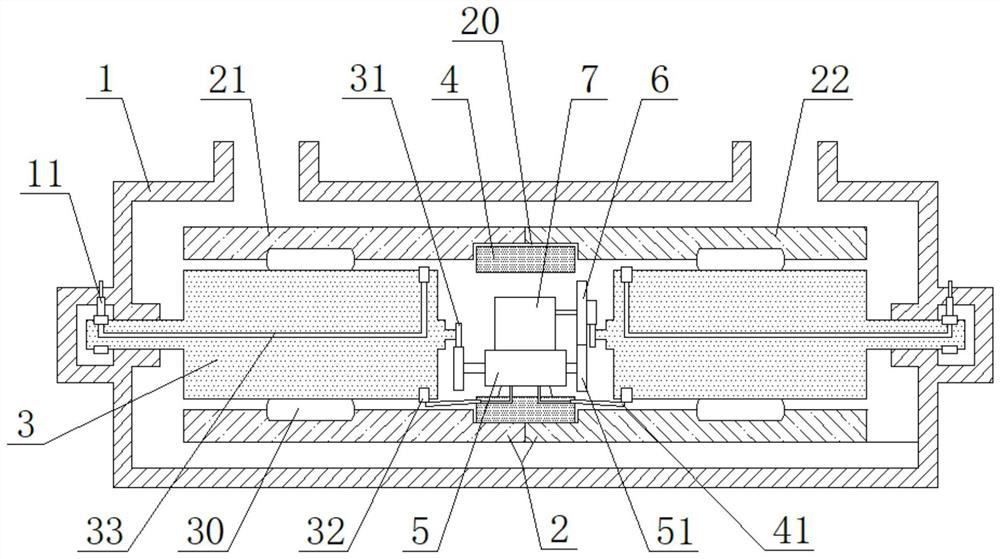

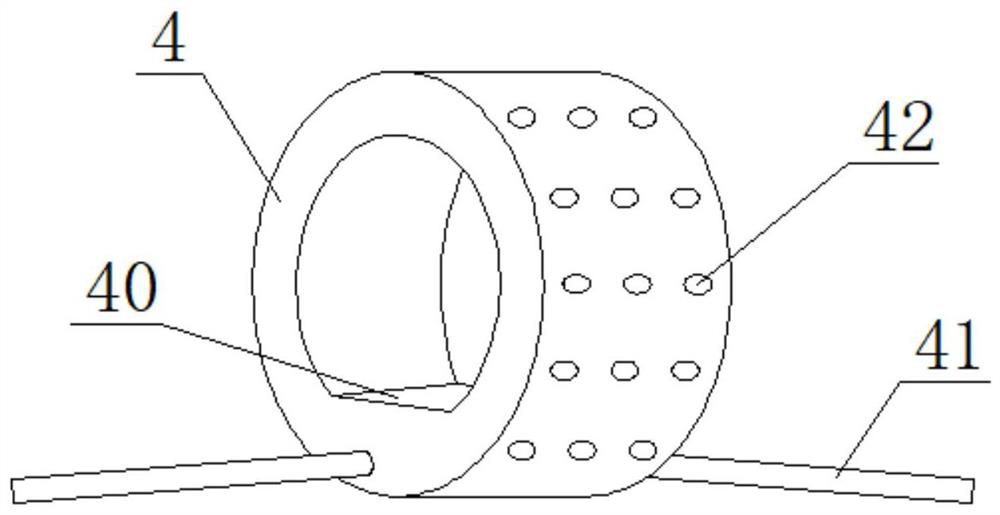

[0013] As shown in the figure, the integrated two-way transmission oil-gas mixing pump includes a volute and an impeller 2 located in the volute 1, wherein the impeller includes a forward impeller 21 and a reverse impeller 22, and the impeller 2 is provided with a "middle" shaped rotating shaft 3, the rotating shaft 3 is connected with the impeller 2 through a key 30, a driven gear 31 is provided at the inner end of the rotating shaft 3, and the outer end of the rotating shaft 3 is connected to the vortex through a bearing The shell 1 is connected, and an annular groove 20 is arranged on the inner wall of the connection of the impeller 2, and a sleeve 4 is arranged in the groove 20, and a double-headed motor 5 is arranged in the sleeve 4. Both ends of the double-headed motor 5 are provided with driving gears 51, wherein one driving gear 51 directly meshes with one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com