Wind turbine gearbox elastic support vibration reduction effect monitoring device and monitoring method

An elastic support, wind turbine technology, applied in the monitoring of wind turbines, wind turbines, motors, etc., can solve the problems of elastic support damage, large calculation errors, impact evaluation, etc., to achieve less parameter variables, reduce calculation errors, and ensure safety. The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

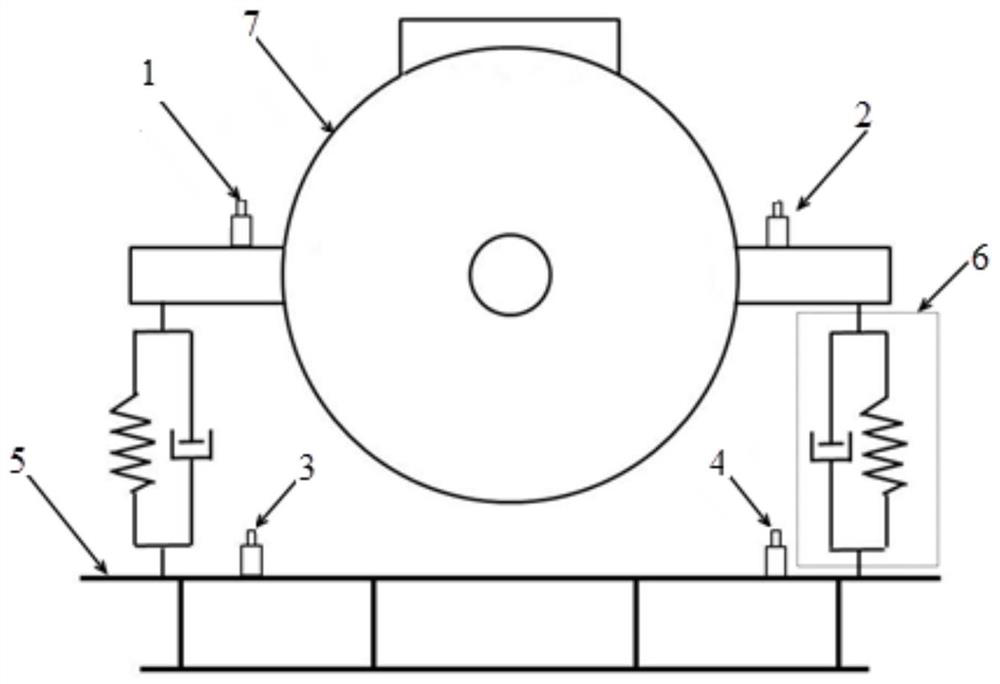

[0036] like figure 1 As shown, a wind turbine gearbox elastic support vibration reduction effect monitoring device, the wind turbine gearbox includes a gearbox frame 5 and a gearbox 7, a torque arm is installed on the gearbox 7, and the bottoms of the two ends of the torque arm are installed vertically There is an elastic support 6, one end of the elastic support 6 is installed on the gear box frame 5, and the other end is connected with the bottom surface of the torsion arm. It is characterized in that the elastic support damping effect monitoring device of the wind turbine gearbox includes several vibration acceleration Sensors, a vibration acceleration sensor is respectively installed at both ends of the upper surface of the torsion arm, respectively the first vibration acceleration sensor 1 and the second vibration acceleration sensor 2, and a vibration acceleration sensor is respectively installed at the two ends of the gear box frame 5, respectively It is the third vibra...

Embodiment 2

[0038] A method for monitoring the vibration reduction effect of an elastic support of a wind turbine gearbox, comprising the following steps:

[0039] S1. According to the device of Embodiment 1, a vibration acceleration sensor is arranged.

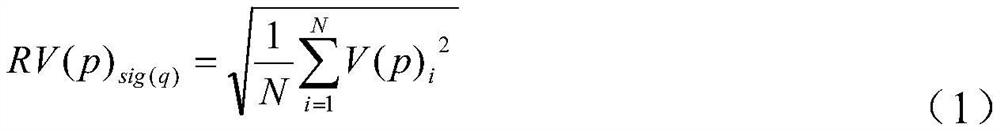

[0040] S2. Collect a set of vibration acceleration sensor signals to obtain a set of vibration acceleration data. Set the sampling frequency of the vibration acceleration sensor before collecting. Considering the calculation amount and monitoring effect comprehensively, the sampling frequency of the four vibration sensors can be set to 3000Hz (the sampling frequency can be set according to the model, but it cannot be lower than 2.5 times the highest meshing frequency) ;

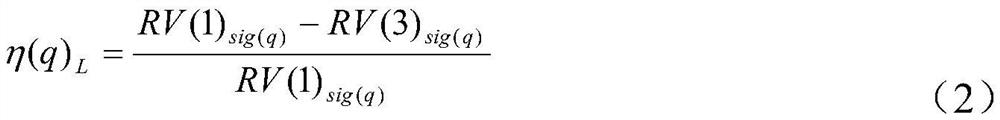

[0041] Considering that the high-frequency vibration of the frame will be aroused during the yaw of the unit against the wind, it is equivalent to adding additional background noise to the third vibration acceleration sensor 3 and the fourth vibration acceleration sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com