Ship-shaped sugarcane ash hanging type salvage pit elevator and sugarcane ash treatment method

An ash-hoisting and hoisting technology is applied in the field of ship-type sugarcane ash hoisting pit hoisting and sugarcane ash processing, and can solve the problems of high sensitivity of bucket elevators, inability to use normally, and inability to separate water and ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

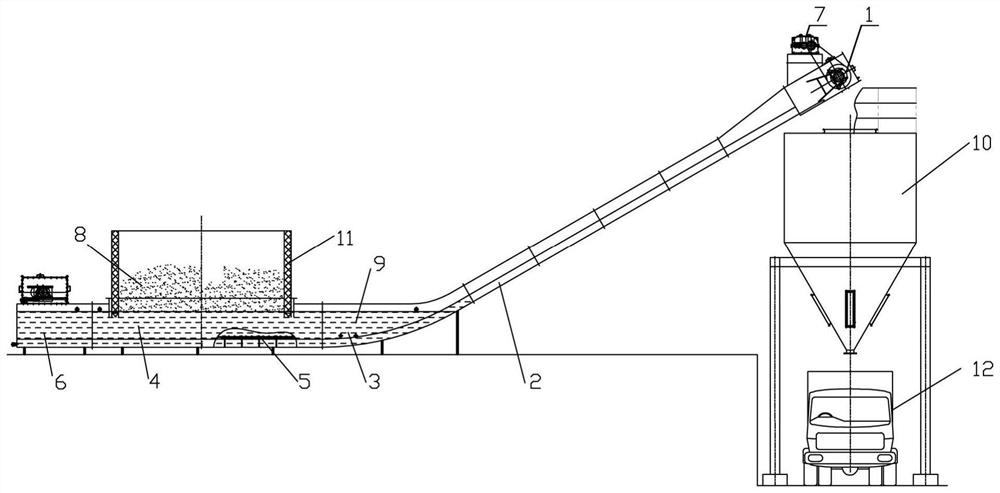

[0065] Such as figure 1 As shown, a boat-shaped sugarcane ash hoisting pit hoist includes a head 1, a lifting section housing 2, a bending section housing 3, a horizontal immersion section housing 4, a bucket chain group 5, a tail section 6, and a drive unit 7 . The head 1, the lifting section housing 2, the bending section housing 3, the horizontal immersion section housing 4, and the tail 6 are sequentially connected to each other to form a whole. Unit 7 drives.

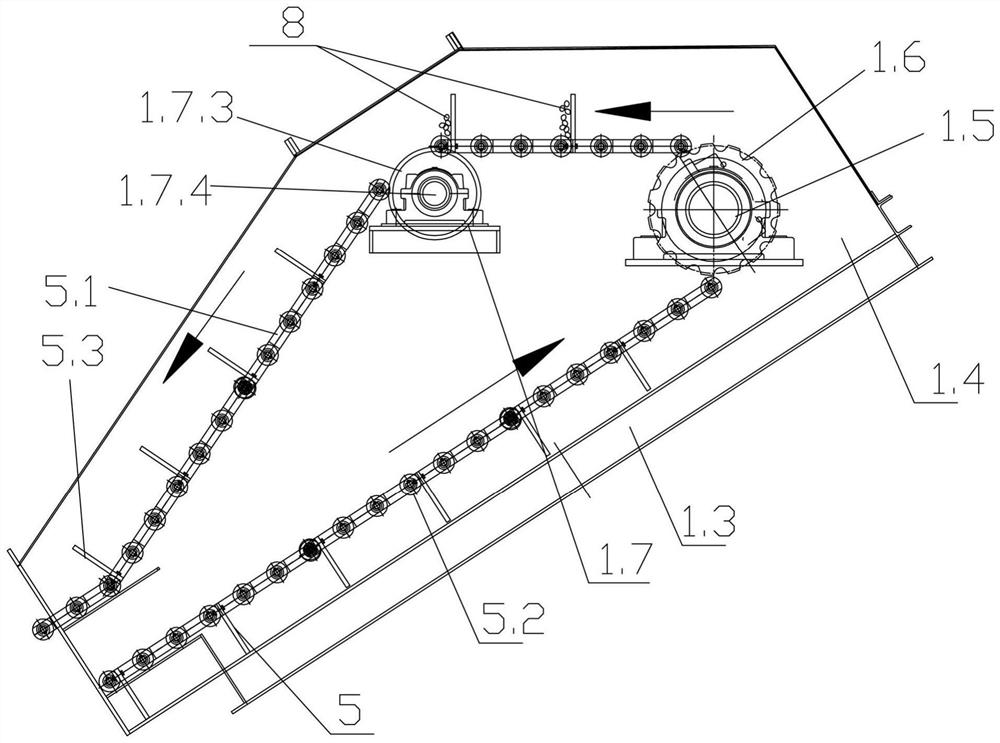

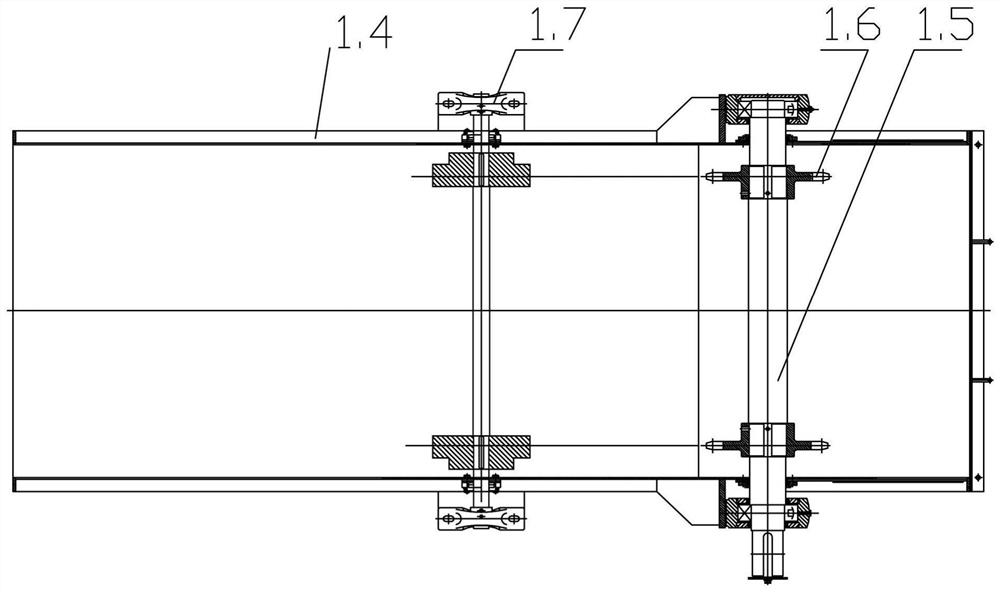

[0066] Such as Figure 2-5 As shown, the head includes a head shell 1.4, the lower end of the head shell 1.4 is provided with a head discharge port 1.3, a head shaft 1.5 is installed in the head shell 1.4, and a pair of head wheels are fixed on the head shaft 1.5 1.6, the conveyor chain 5.1 in the bucket chain group 5 meshes with the head wheel 1.6 and moves with the rotation of the head wheel 1.6.

[0067] Such as figure 2 , Figure 5 As shown, an unloading mechanism 1.7 is installed near the head shaft 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com