Novel vertical lifting machine

A hoist, vertical technology, applied in the field of color sorters, can solve the problems of incomplete discharge, reduced production efficiency, material returning to the hoist base, etc., to avoid the phenomenon of returning materials, improve production efficiency, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

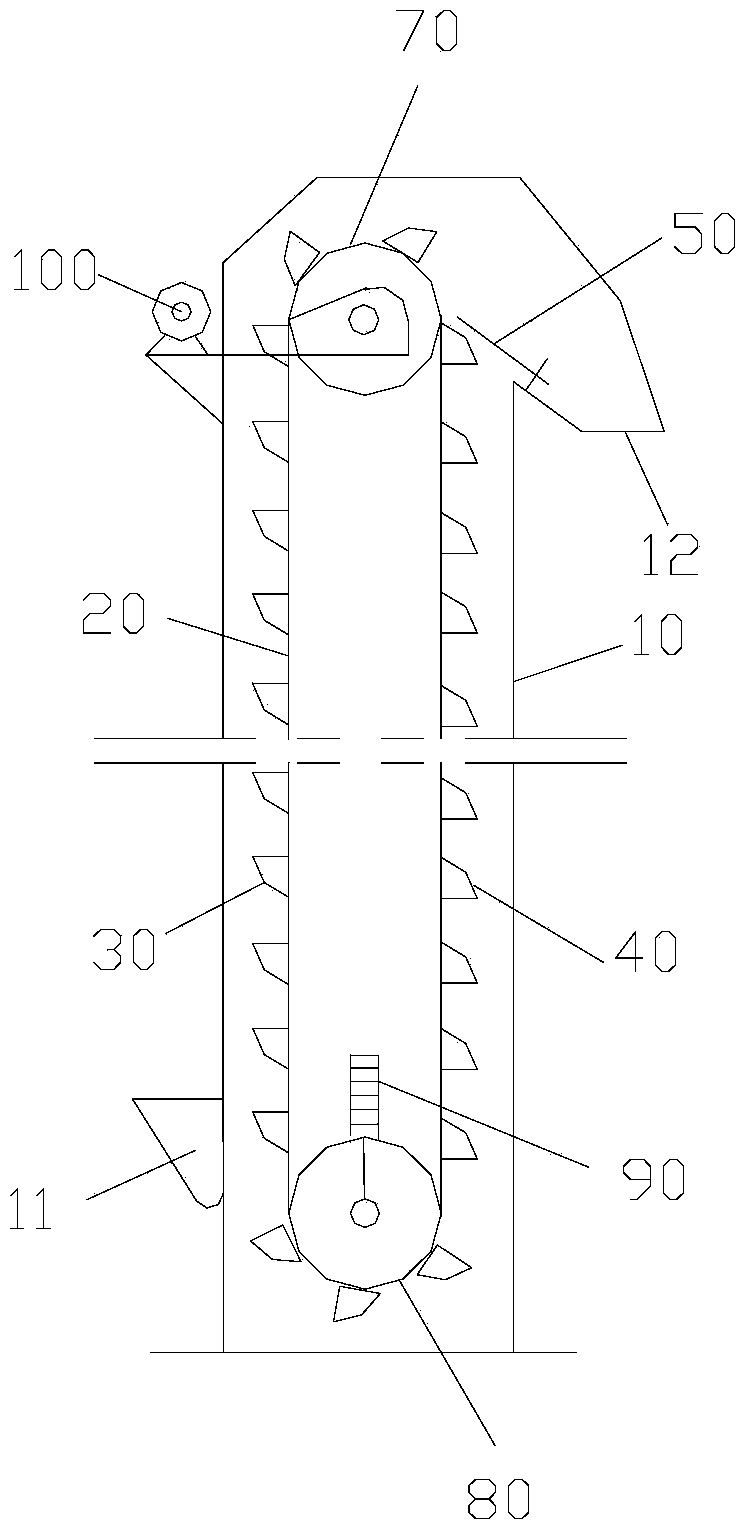

[0010] The following is attached with the manual Figure 1-3 The technical scheme and structure of the present invention are described to facilitate the understanding of those skilled in the art.

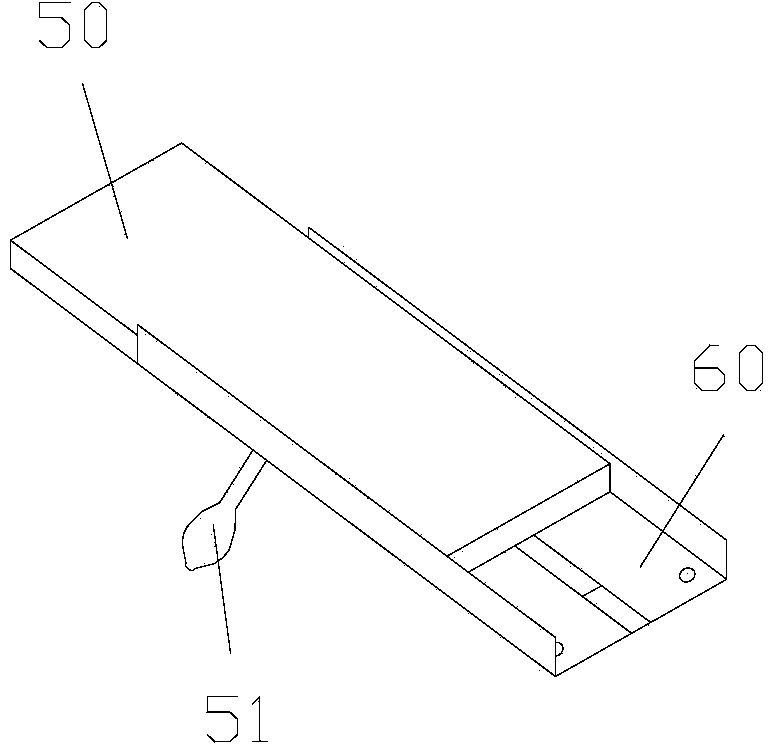

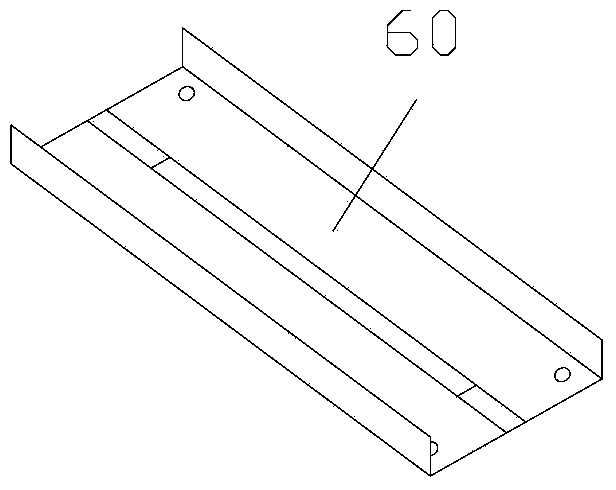

[0011] Such as figure 1 As shown, a novel vertical hoist includes a casing 10 provided with a material inlet 11 and a material outlet 12. The inside of the casing 10 is provided with a ring-shaped traction mechanism 20 and is evenly affixed to the traction mechanism 20. The upper hopper 30 and the lower hopper 40, a movable adjustment plate 50 is provided between the discharge port 12 and the uppermost downward hopper 30, and the inside of the casing 10 is provided with a movement for the adjustment plate 50. Rail 60. By providing a movable regulating plate 50 between the discharge port 12 and the uppermost descending hopper 40, when the vertical hoist is in the lifting process, the regulating plate 50 blocks the gap between the descending hopper 40 and the discharge port 12. Cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com