Electronic rotor paint dipping device with relatively high efficiency

An electronic rotor, a relatively high technology, applied in the field of electronic rotor paint dipping device, can solve the problems of low efficiency of rotor paint dipping, small amount of paint dipping, unfavorable rotor batch paint impregnation, etc., to improve efficiency, ensure production volume, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

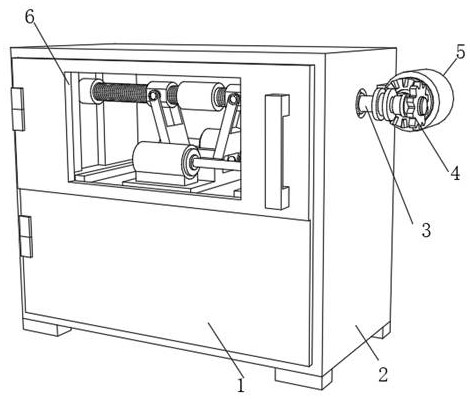

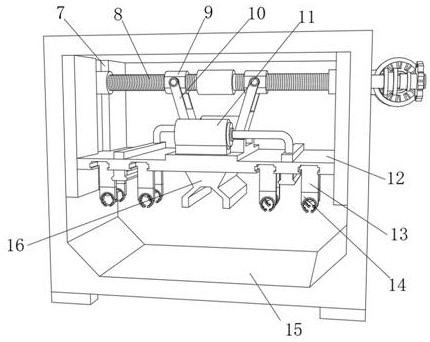

[0033] A high-efficiency electronic rotor impregnation device, such as Figure 1-4 As shown, it includes a main body box 2, the front side outer wall of the main body box 2 is hinged with a box door 1, and the top front outer wall of the main body box 2 is provided with a glass observation window 6, and the side outer wall of the main body box 2 is passed through a support. The plate is fixed with a motor 5, and the output end of the motor 5 is sleeved with a main gear, and the peripheral teeth of the main gear are meshed with a secondary gear 4, and the peripheral inner wall of the secondary gear 4 is inserted with a rotating shaft 3, and the end of the rotating shaft 3 is provided with Lifting mechanism, the inner walls of both sides of the main body box 2 are respectively fixed with guide plates by bolts, and the opposite side outer walls of each guide plate are provided with chute 7, the bottom end of the lifting mechanism is fixed with a sliding plate 12 by bolts, and the ...

Embodiment 2

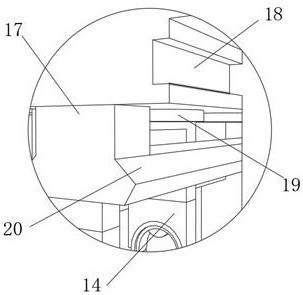

[0039] A high-efficiency electronic rotor impregnation device, such as Figure 5 As shown, in order to effectively promote the guidance of the wind; this embodiment makes the following improvements on the basis of Embodiment 1: each of the top outer walls of the air guide ring 19 is threaded with an air nozzle 27, and the air guide ring 19 is close to the air nozzle There is an air outlet 24 below 27, and the inner walls on both sides of the air outlet 24 near the bottom of the air nozzle 27 are connected with fixed shafts 26 by threads respectively, and the circumferential outer wall of the fixed shaft 26 is sleeved with an air guide sphere 25, and the bottom inner wall of the air outlet 24 The structure is an outwardly inclined structure; when the gas enters the air outlet 24 through the air nozzle 27, it effectively drives the rotation of the air guide sphere 25, so that the air outlet 24 is filled with gas, and the inner wall of the bottom inner ring of the air outlet 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com