Mechanical equipment for preparing regenerated sand-gravel material by using construction waste particles

A technology of construction waste and mechanical equipment, which is applied in grain processing, solid separation, filtration and screening, etc., can solve the problems of construction waste not being able to be effectively recycled, waste of resources, and damage to the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

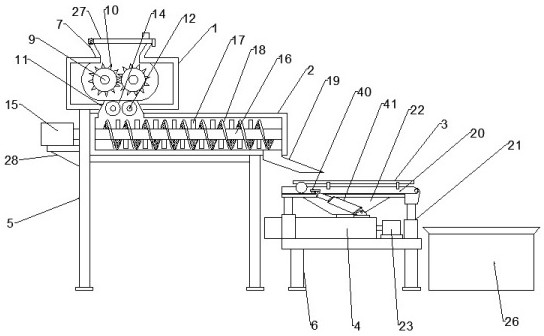

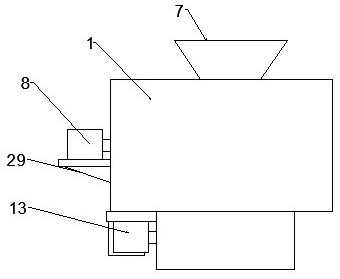

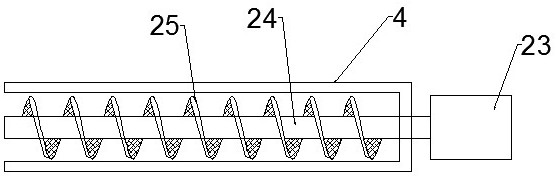

[0026] Such as Figure 1-4 As shown, according to the embodiment of the present invention, the mechanical equipment for producing recycled sand and gravel by using construction waste particles includes a crushing box 1, a mixing drum 2, a screening device 3 and a pushing drum 4. The crushing box 1 and the The mixing drum 2 is fixedly connected with the support frame 5, the screening device 3 and the pushing drum 4 are all located at the upper end of the fixing frame 6, and the screening device 3 and the pushing drum 4 are located at the stirring The lower end of one side of the cylinder 2, the crushing box 1 is located on the upper side of the mixing drum 2, the upper middle of the crushing box 1 is provided with a feed hopper 7, and the middle of one end of the crushing box 1 is a A crushing motor 8 is arranged on the side, and both ends of the inner middle of the crushing chamber of the crushing box 1 are provided with a crushing shaft 9, and the outside of the crushing shaf...

Embodiment 2

[0029] Such as Figure 1-4 As shown, the upper end of the feed hopper 7 is provided with a cover 27, and one side of the upper end of the cover 27 is provided with a handle. Both the support frame 5 and the fixed frame 6 are composed of a support plate and a support column, the bottom ends of the support columns are all provided with expansion plates, and the undersides of the expansion plates are all provided with anti-skid pads. The stirring motor 15 is fixedly connected to the support frame 5 through a connecting frame 28 , and the connecting frame 28 is fixedly connected to the stirring motor 15 through bolts. Both the processing motor 13 and the crushing motor 8 are fixedly connected to the crushing box 1 through a receiving frame 29 . The damaged knives 17 are alternately connected between the spiral knives 18 , and the damaged knives 17 are fixedly connected to the rotating shaft 16 by welding on the helical knives 18 . The upper corners of the waste bin 26 are all pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com