Fracturing construction real-time water quality automatic online viscosity adjusting system and method

A viscosity and fracturing technology, applied in the field of fracturing fluid addition, can solve the problems of viscosity adjustment of construction fluid and limited range of fracturing fluid performance adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

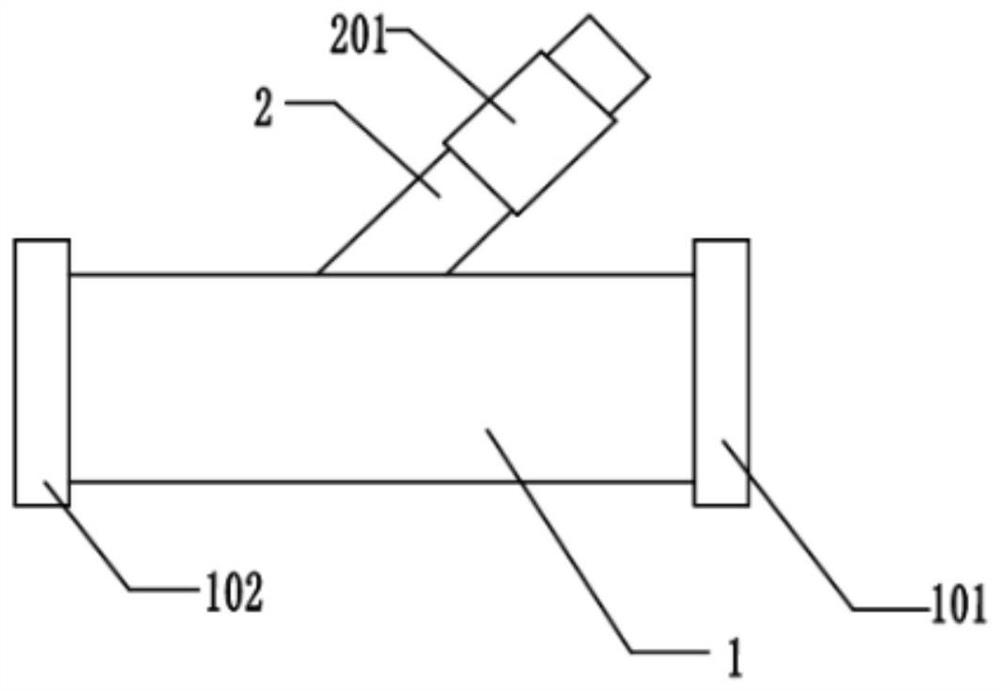

[0047] The embodiment is basically as attached figure 1 Shown: The real-time water quality automatic online viscosity adjustment system for fracturing construction, including the central control unit and the water quality monitoring unit, viscosity monitoring unit and liquid addition control unit respectively connected to the central control unit; the water quality monitoring unit, viscosity monitoring unit and The liquid adding control unit is installed on the sand mixer.

[0048] The central control unit includes a central processing unit with computing and processing capabilities and a memory connected to it with storage functions. In this embodiment, a commonly used PLC control cabinet with computing, processing and storage functions is selected.

[0049] The water quality monitoring unit includes an ion detection probe extending into the mixing tank of the sand mixer, and the ion detection probe is electrically connected with the PLC control cabinet. The ion detection pr...

Embodiment 2

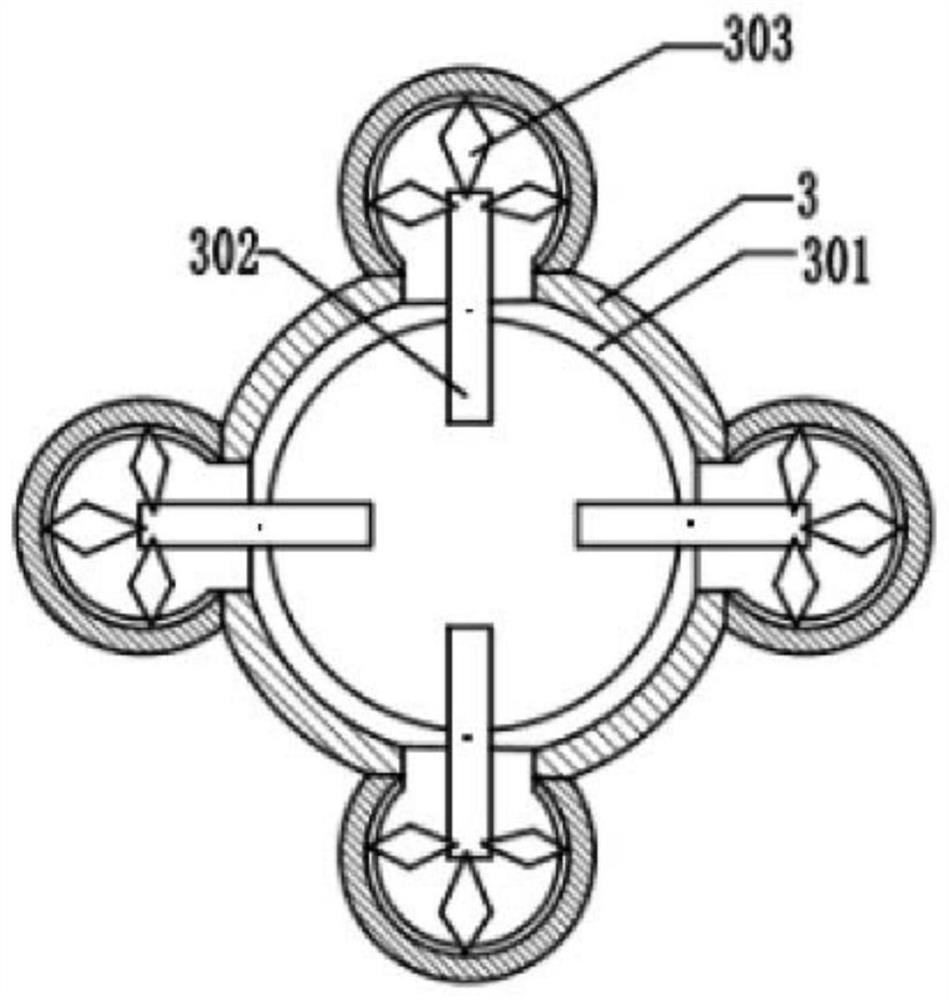

[0086] In this embodiment, a prompt tube 3 is installed on the port of the branch tube 2 . The outer surface of the end of the port of the branch pipe 2 is provided with an external thread, and the prompting pipe 3 is a tubular structure, and an internal thread is provided on one end of the pipe 3, which is threadedly connected with the end of the branch pipe 2, and the other end of the prompting pipe 3 The mouth of the pipe is provided with both an internal thread and an external thread, so that it can be threadedly connected with the medicine box conveniently.

[0087] Such as image 3As shown, in the pipe wall of the prompting tube 3, there is a loudspeaker cavity protruding outwards to form a cavity structure. A fixed ring 301 is inlaid at the mouth of the loudspeaker cavity, and a plurality of radially arranged rings are hinged on the fixed ring 301. Blocking piece 302, one end of blocking piece 302 stretches in the prompting tube 3, is used for contacting with the medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com