A kind of tobacco uniform roasting equipment

A baking equipment and uniform technology, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as affecting the baking quality of tobacco leaves and low uniformity of tobacco, reduce stacking phenomenon, improve baking efficiency, and help dehydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Attached to the following Figure 1-7 This application will be described in further detail.

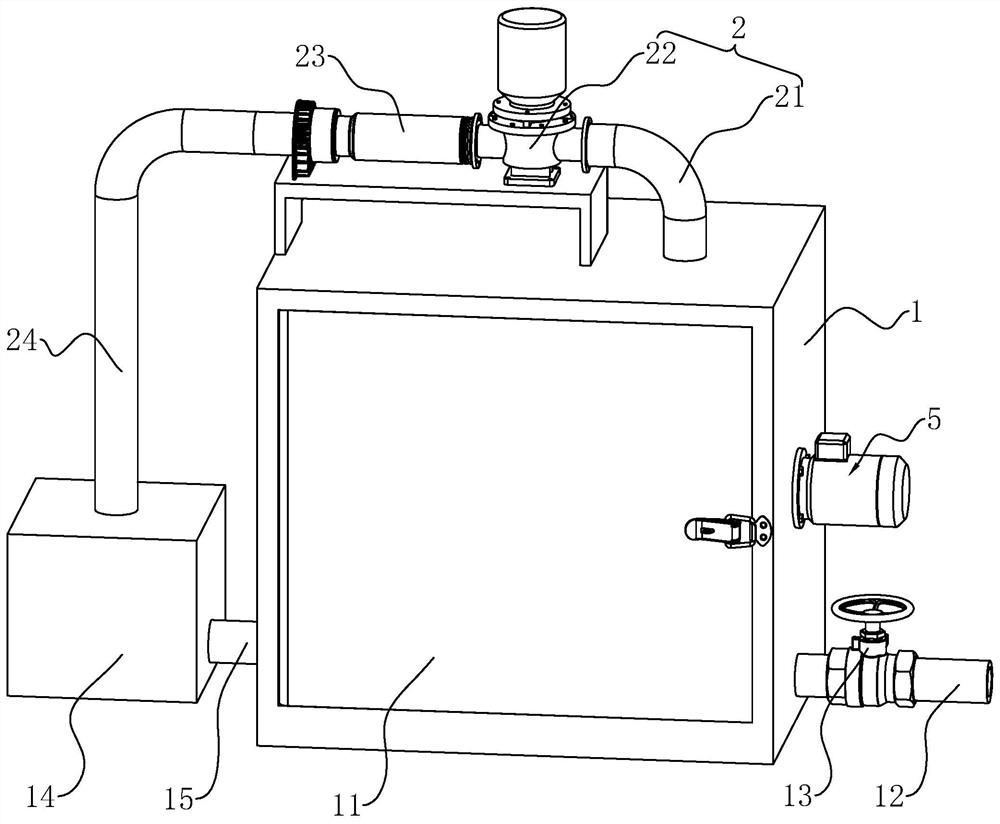

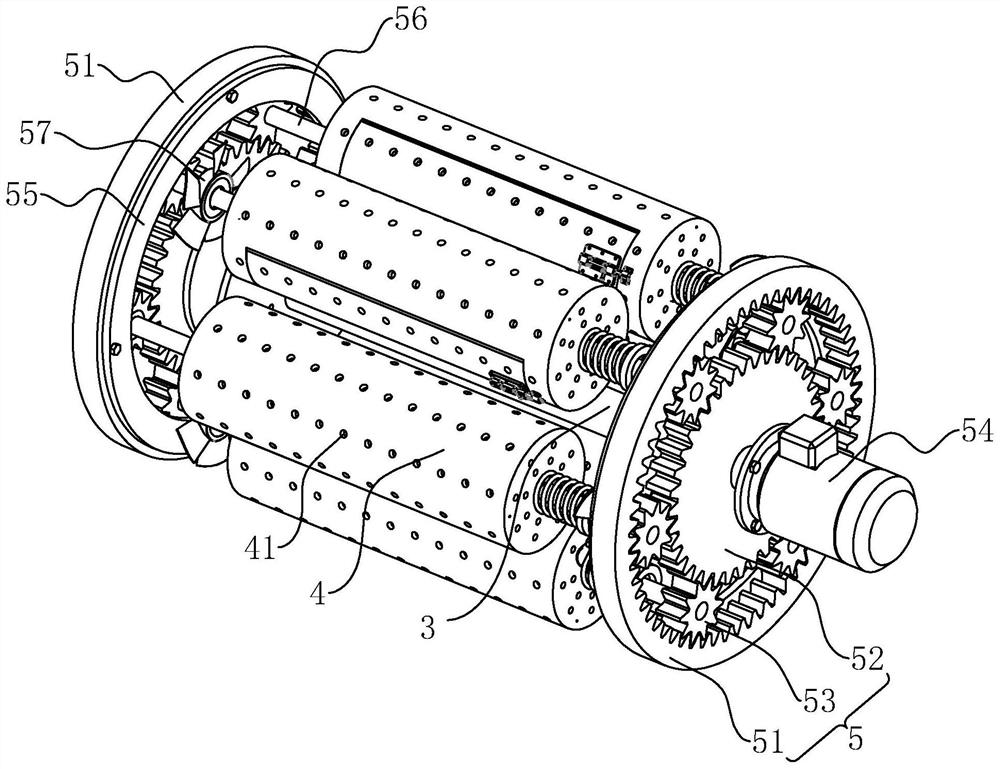

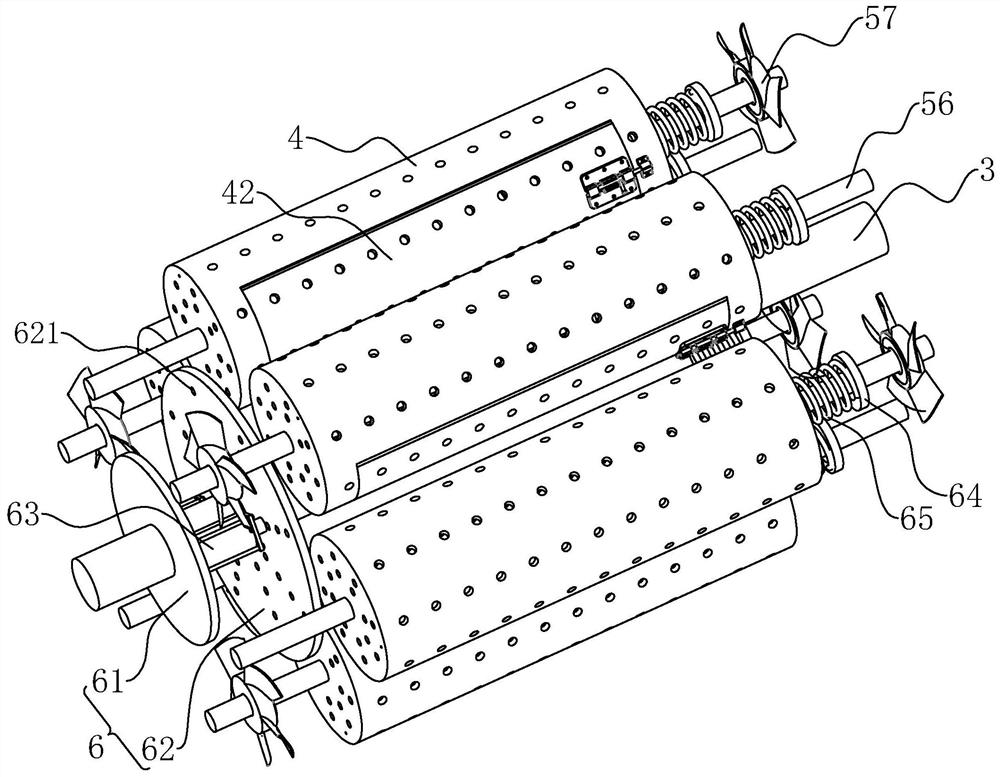

[0040] The embodiment of the present application discloses a tobacco uniform roasting equipment, refer to figure 1 , figure 2 , including a box 1, a heating device 2, a mounting shaft 3 built into the box 1, a plurality of placing rollers 4 that revolve around the axis of the mounting shaft 3 and rotate around its own axis, and a rotating device 5 that drives the placement roller 4 to move. .

[0041] refer to figure 1 One side of the box body 1 is hinged with a box door 11 , the bottom of the side wall of the box body 1 is connected with a drain pipe 12 , and the drain pipe 12 is provided with a shut-off valve 13 . A flue gas treatment box 14 is connected to the outside of the box body 1 through a pipe 15 , and a filter cotton (not shown in the figure) is provided in the flue gas treatment box 14 only for gas to pass through. The heating device 2 includes a hot air pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com