Pond bait casting device

A pond and chassis technology, applied in agricultural machinery and implements, fish farming, agriculture, etc., can solve the problems of limiting the production of efficient fish bait, reducing the income of farmers, and increasing the pollution of water quality, so as to reduce the cost of factory farming, The effect of saving bait resources and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

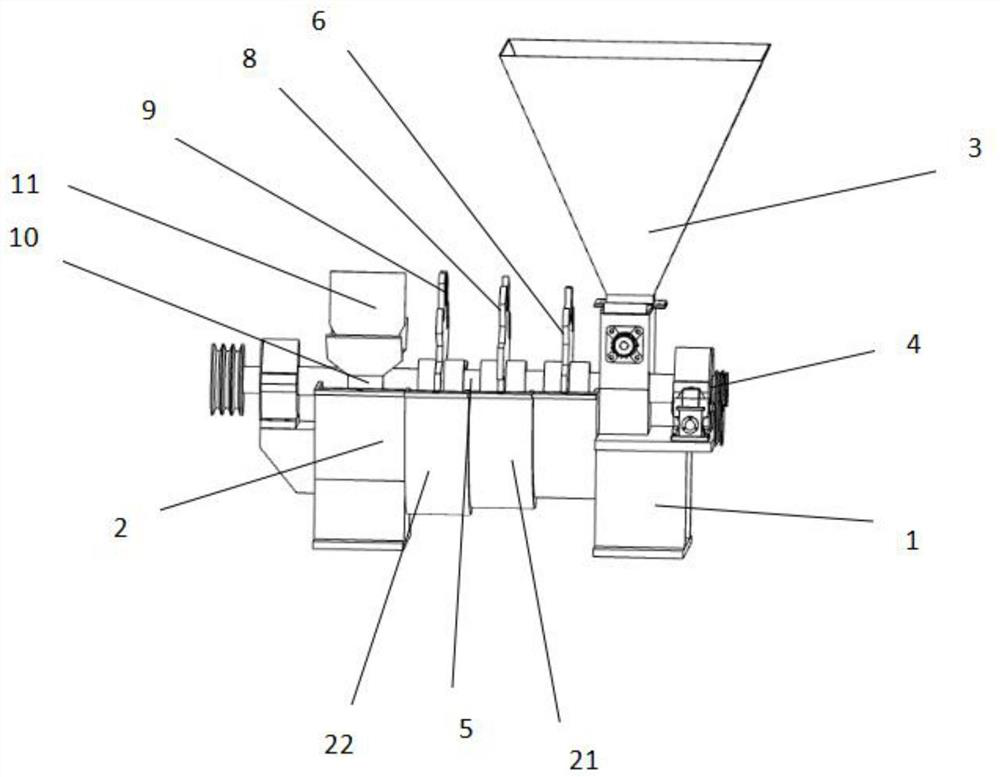

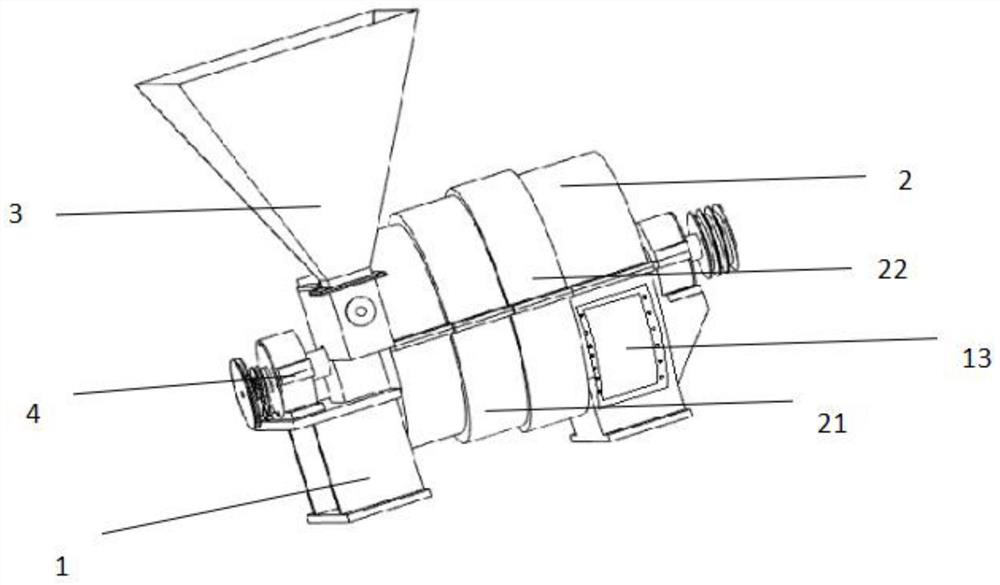

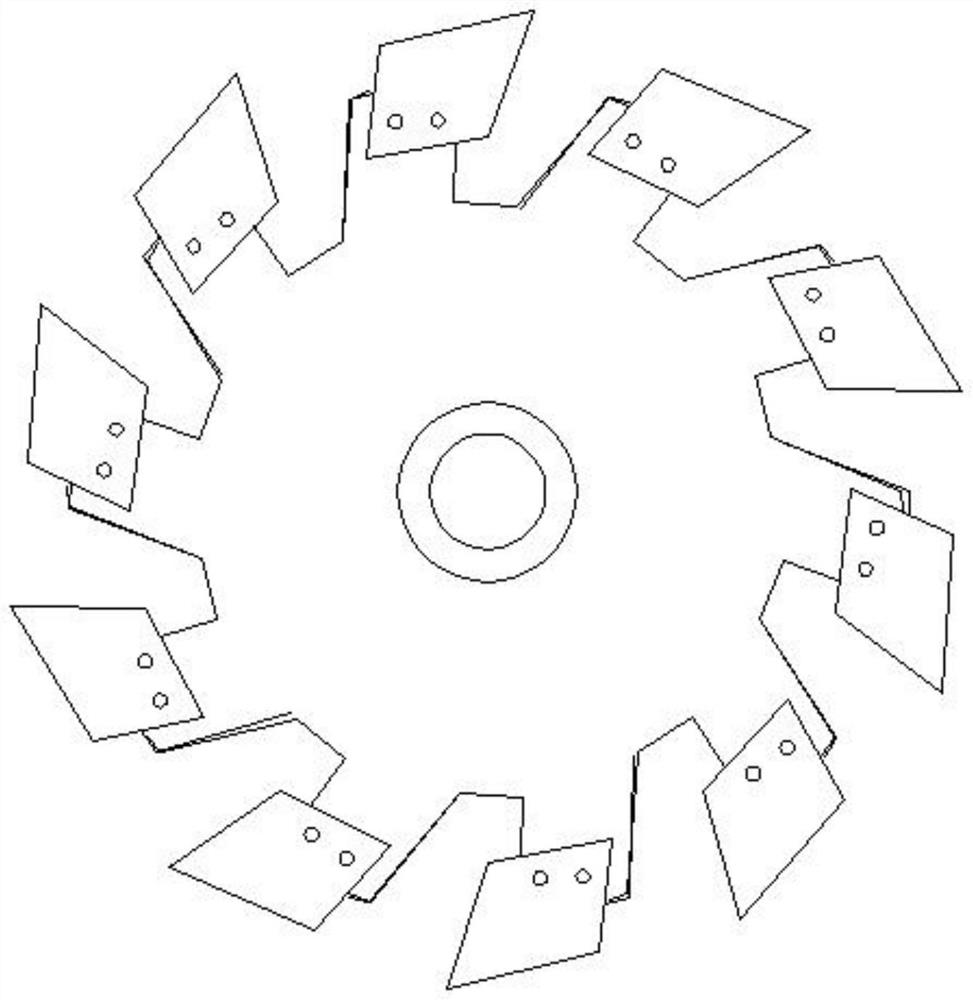

[0022] like Figure 1 to Figure 4 As shown, a pond baiting device includes a frame 1, a cabinet 2 and an upper hopper 3, and is characterized in that the frame 1 is provided with an upper hopper 3, and the upper hopper 3 is connected to the cabinet 2, and the The cabinet 2 is provided with a first boss 21 and a second boss 22, a reduction motor 4 is arranged outside the cabinet 2, a rotating shaft 5 is arranged inside the cabinet 2, and the reduction motor 4 is connected with the rotation shaft 5 , the rotating shaft 5 is sequentially provided with a first crushing mechanism, a second crushing mechanism, a third crushing mechanism and a throwing mechanism 10, and the first crushing mechanism includes a first crushing disc 6 and is arranged on the first crushing disc 6 A plurality of first blades 7, the second crushing mechanism includes a second crushing disc 8 and a plurality of second blades arranged on the second crushing disc 8, the third crushing mechanism includes a thir...

Embodiment 2

[0028] like Figure 5 As shown, a pond baiting device includes a frame 1, a cabinet 2 and an upper hopper 3, and is characterized in that the frame 1 is provided with an upper hopper 3, and the upper hopper 3 is connected to the cabinet 2, and the The cabinet 2 is provided with a first boss 21 and a second boss 22, a reduction motor 4 is arranged outside the cabinet 2, a rotating shaft 5 is arranged inside the cabinet 2, and the reduction motor 4 is connected with the rotation shaft 5 , the rotating shaft 5 is sequentially provided with a first crushing mechanism, a second crushing mechanism, a third crushing mechanism and a throwing mechanism 10, and the first crushing mechanism includes a first crushing disc 6 and is arranged on the first crushing disc 6 A plurality of first blades 7, the second crushing mechanism includes a second crushing disc 8 and a plurality of second blades arranged on the second crushing disc 8, the third crushing mechanism includes a third crushing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com