Roller bearing capable of realizing self-power-generation monitoring

A kind of roller bearing and self-generating technology, applied in the direction of roller bearing, rolling contact bearing, bearing of rotating motion, etc., can solve the problems of magnetic interference, depolarization of piezoelectric ceramics, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

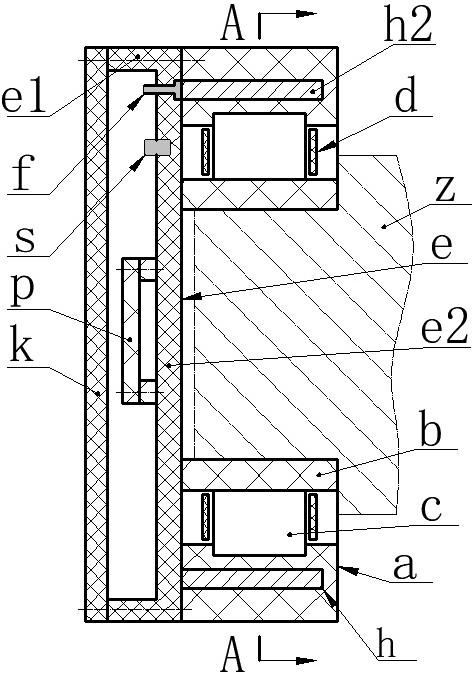

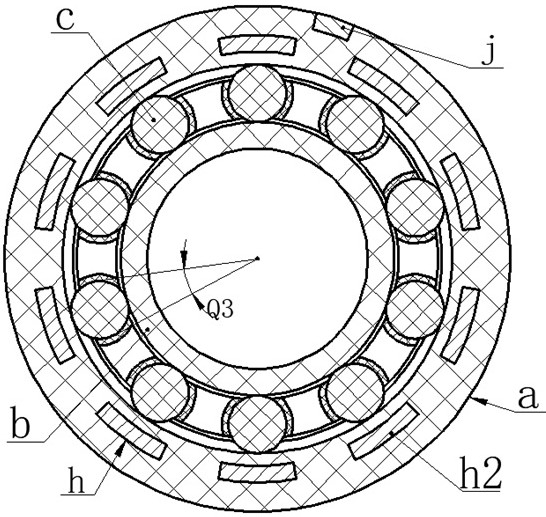

[0018] The present invention proposes a self-generating and monitoring roller bearing, which mainly includes an inner ring b, an outer ring a, a roller c, a bracket d, a shell e, a sensor s and a circuit board p.

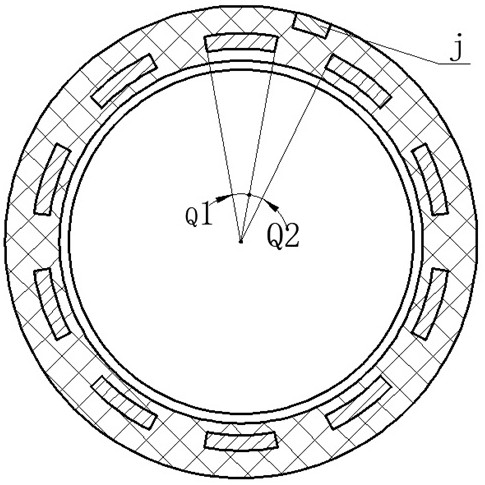

[0019] There is an annular raceway on the inner edge of the outer ring a, the outer ring a is installed on the inner ring b through the bracket d and the roller c, and the roller c is embedded in the raceway of the outer ring a; the shell bottom e2 of the shell e It is installed on the end of the outer ring a or inner ring b through screws, the end of the shell wall e1 is installed with an end cover k through screws, and the circuit board p, sensor s, and terminal f are installed on the bottom e2 of the shell. An auxiliary electrode j is provided on the ring a, and the sensor s, the terminal f and the auxiliary electrode j are connected to the circuit board p through different wire groups.

[0020] There is an electrode h inside the outer ring a or inner ring b, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com