Automatic efficient crude oil impurity removal equipment

A technology of crude oil and equipment, which is applied in the field of automatic and efficient crude oil impurity removal equipment, and can solve problems such as waste of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

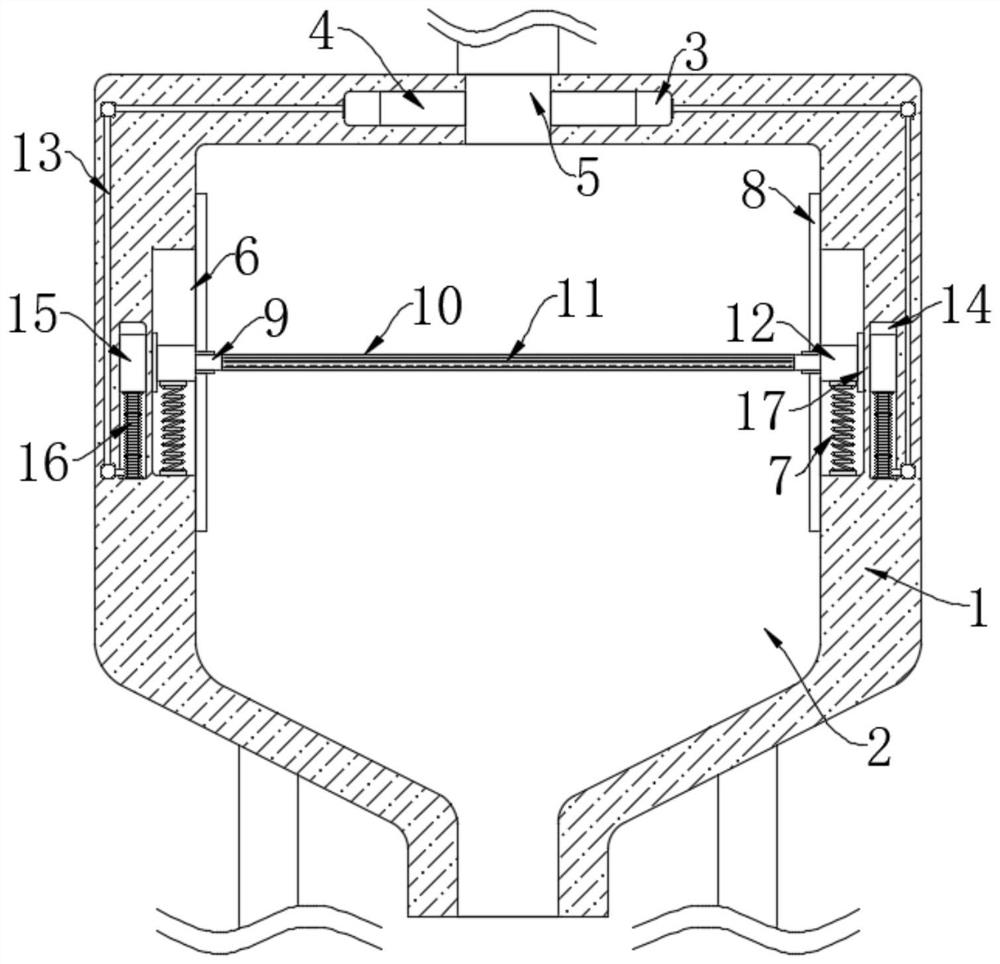

[0020] refer to figure 1 , an automatic high-efficiency crude oil removal equipment, including a housing 1, the housing 1 is a filter box in actual use, a filter chamber 2 is opened in the housing 1, the inner bottom of the filter chamber 2 communicates with the outside world, and the filter chamber 2 The inner bottom is a curved surface, which is convenient for crude oil to flow out of the filter chamber 2. The lower end of the housing 1 is fixedly connected to the ground through a plurality of support rods. An oil inlet pipe is arranged on the top of the housing 1. The oil inlet pipe communicates with the oil inlet 5. When in use, the The oil inlet pipe can be connected with the oil inlet pipe;

[0021] The shaking mechanism, the shaking mechanism includes two shaking grooves 6 symmetrically opened on the inner wall of the filter chamber 2 sides, the two shaking grooves 6 are provided with sliding blocks 12, and the front and rear sides of the two sliding blocks 12 are respe...

Embodiment 2

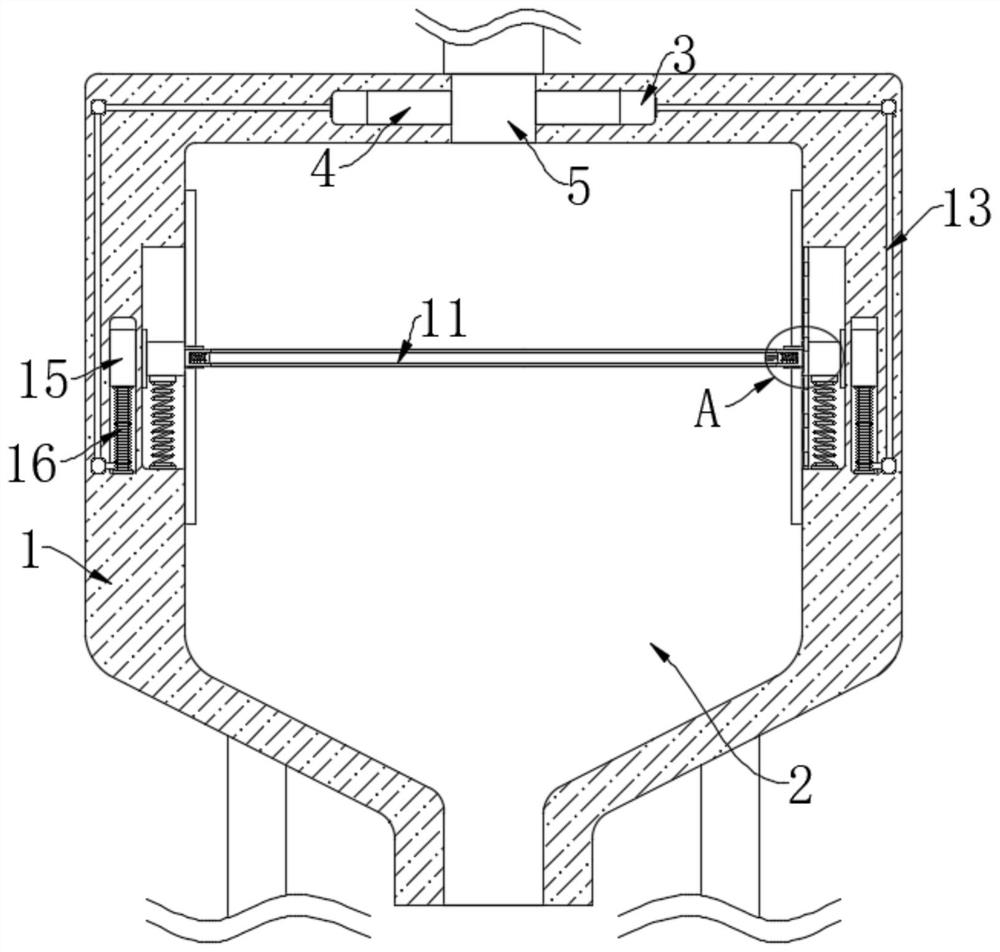

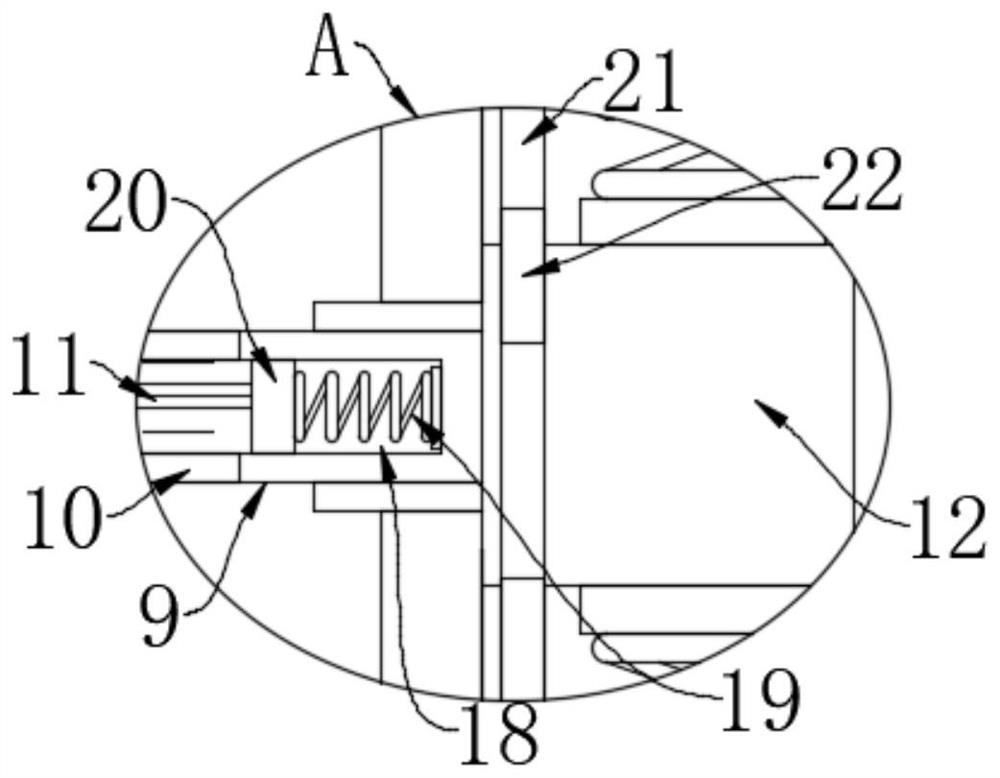

[0026] refer to Figure 2-3The difference between this embodiment and Embodiment 1 is that both sides of the opening 10 are provided with sloshing grooves 18, and the two sloshing grooves 18 are all provided with a third magnetic block 20, and the two third magnetic blocks 20 are all connected with each other. Corresponding to the inwall sliding connection of the shaking groove 18, two third magnetic blocks 20 are elastically connected to the inner wall of the shaking groove 18 by the second spring 19 near the side of the shaking groove 6, and the two third magnetic blocks 20 are far away from the side of the shaking groove 6. One side is fixedly connected with the both sides of filter screen 11 respectively, and vertically is provided with guide rod 21 in one of shaking groove 6, and guide rod 21 runs through corresponding first magnetic block 17, and the two ends of guide rod 21 are connected with corresponding shaking groove 6 respectively. The inner top and inner bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com