Drill site tracking monitoring method and device

A technology for tracking monitoring and drilling field, applied in the field of drilling, which can solve problems such as low operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

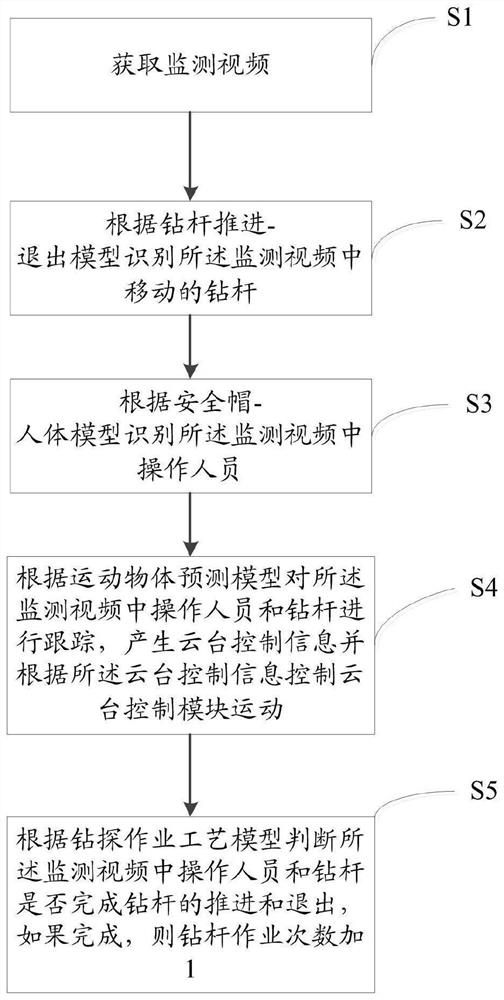

[0045] figure 1 It is the flow chart of the drilling site tracking and monitoring method in Embodiment 1 of the present invention, such as figure 1 As shown, the drilling site tracking monitoring method includes:

[0046] S1: Obtain monitoring video.

[0047] S2: Identify the moving drill pipe in the monitoring video according to the drill pipe advance-exit model.

[0048] S3: Identify the operator in the monitoring video according to the helmet-mannequin.

[0049] S4: Track the operator and the drill pipe in the monitoring video according to the moving object prediction model, generate pan-tilt control information, and control the movement of the pan-tilt control module 3 according to the pan-tilt control information.

[0050] S5: According to the drilling operation process model, it is judged whether the operator and the drill pipe in the monitoring video have completed the advancement and withdrawal of the drill pipe. If completed, the number of drill pipe operations is ...

Embodiment 2

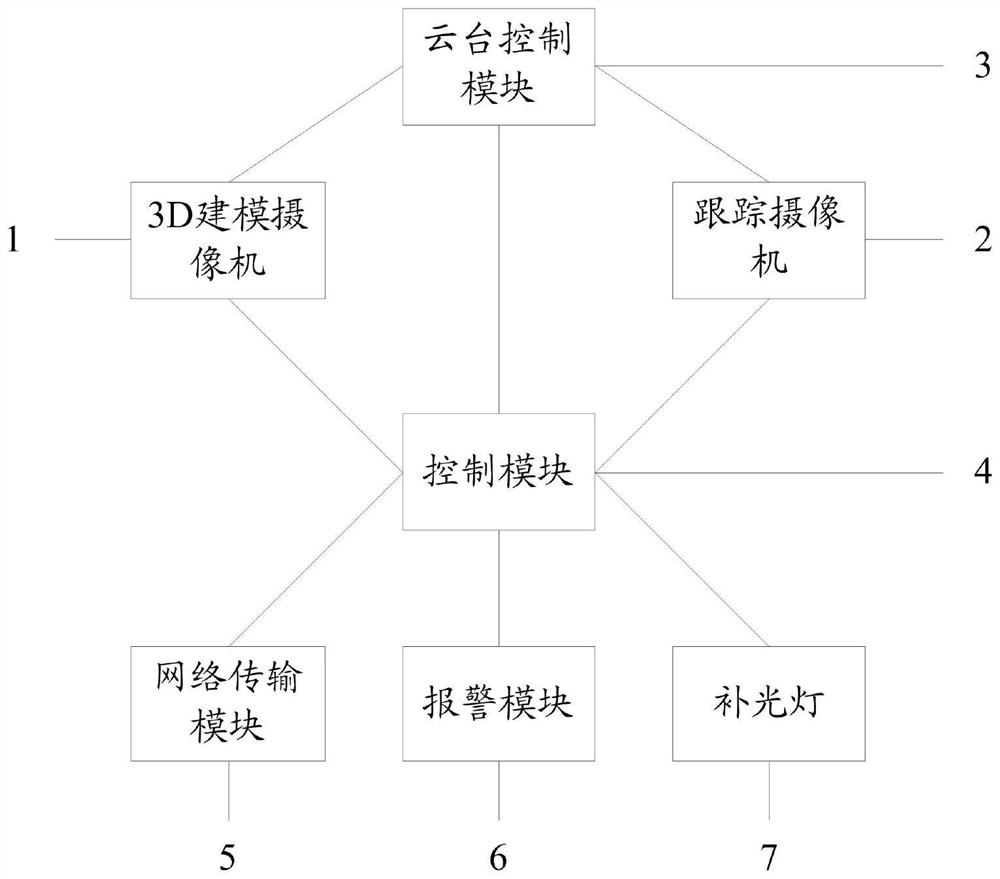

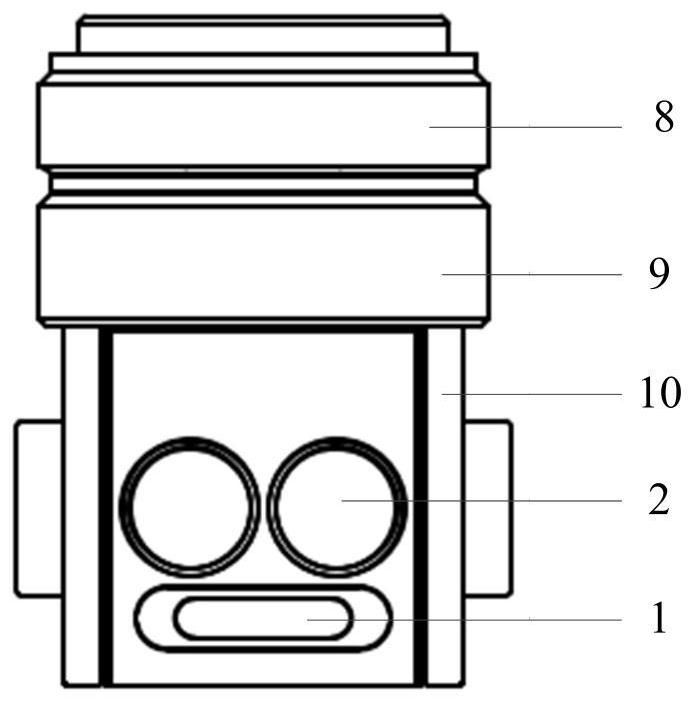

[0053] figure 2 It is a structural block diagram of the drilling site tracking and monitoring device in Embodiment 2 of the present invention, as figure 2As shown, the drilling site tracking and monitoring device includes: a 3D modeling camera 1 , a tracking camera 2 , a pan-tilt control module 3 and a control module 4 . The cloud platform control module 3 is connected with the tracking camera 2 and the 3D modeling camera 1 respectively, and the control module 4 is connected with the cloud platform control module 3, the 3D modeling camera 1 and the tracking camera 1 respectively. Camera 2 is connected. The 3D modeling camera 1 is used to monitor the operation face to be drilled and generate a 3D video. The tracking camera 2 is used for real-time tracking and monitoring of operators and drill pipes to generate monitoring videos. The pan-tilt control module 3 is used to drive the tracking camera 2 and the 3D modeling camera 1 to move. The control module is configured to ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com