Anti-demagnetization control method for deep well permanent magnet synchronous motor based on temperature rise model reconstruction

A permanent magnet synchronous motor, model reconstruction technology, applied in motor control, AC motor control, electronic commutation motor control and other directions, can solve the problems of motor protection, failure, slow demagnetization, etc., to prolong the service life, simple, convenient and reliable , The effect of preventing demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

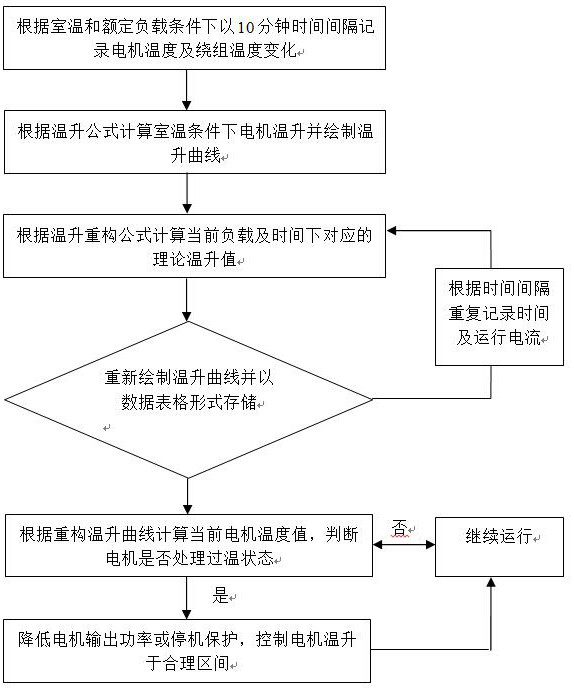

[0033] Such as Figure 1-2 Shown: the present invention provides a kind of deep well permanent magnet synchronous motor anti-demagnetization control method based on temperature rise model reconstruction, comprises the following steps:

[0034] S1. Record the motor temperature and winding temperature changes at 10-minute intervals under room temperature and rated load conditions;

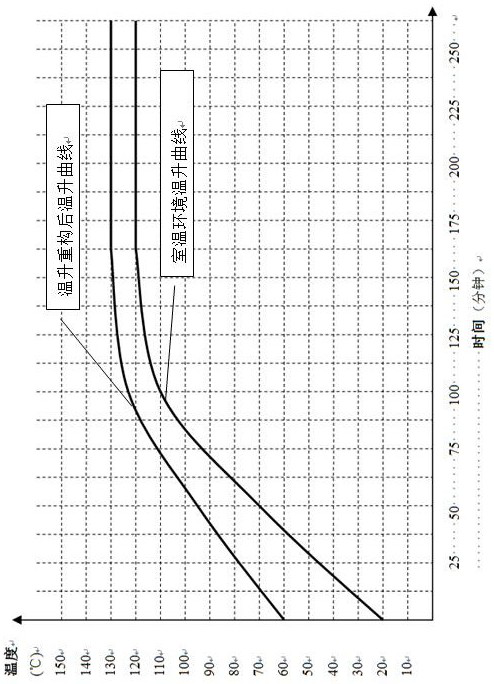

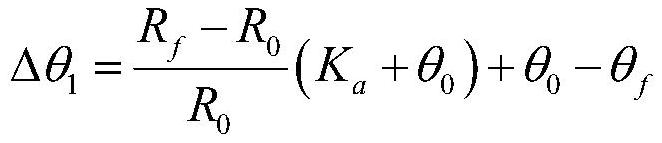

[0035] S2. Calculate the temperature rise of the motor at room temperature according to the temperature rise formula and draw the temperature rise curve;

[0036] S3. Calculate the corresponding theoretical temperature rise value under the current load and time according to the temperature rise reconstruction formula;

[0037] S4. Repeatedly record the time and operating current according to the time interval;

[0038] S5. Redraw the temperature rise curve according to the calculated theoretical temperature rise and time point and store it in the form of a data table;

[0039] S6. Calculate the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com