Multi-pendulum type automatic centering valve clack sealing structure

A technology of automatic centering and sealing structure, applied in valve devices, connecting components, engine components, etc., can solve problems such as valve leakage failure, aggravated environmental pollution, etc., and achieve the effect of improving work efficiency and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

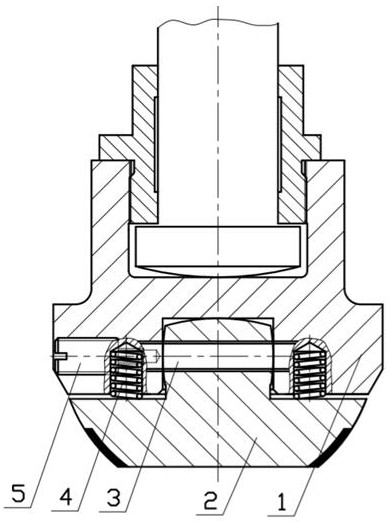

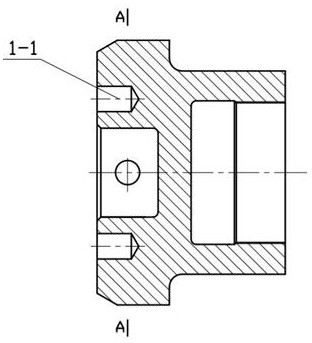

[0016] refer to Figure 1-4 , a multi-swing type automatic centering and sealing valve clack structure, including a valve clack 2 and a valve clack seat 1, the upper end of the main body of the valve clack 2 is a valve clack head 2-1, and the valve clack head 2-1 is in the shape of a spherical tank body; used for centering connection with valve disc seat 1 and realizing automatic centering of valve disc sealing surface; there is a swing gap adjacent to valve disc 2 and valve disc seat 1, which is used for valve disc head 2-1 to swing and align .

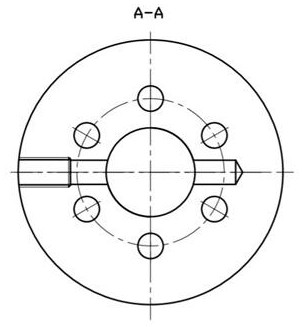

[0017] The swing gap is realized by the pre-tightening force of the spring. The end surface of the disc seat 1 adjacent to the valve disc 2 and the disc seat 1 is evenly distributed with a spring hole 1-1, and a pre-loaded spring hole 1-1 is installed in the spring hole 1-1. Tighten spring 4. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com