Offshore multifunctional combined buoy

A combined and multi-functional technology, applied in buoys, special-purpose ships, ships, etc., can solve the problems of large number of fastening screws, difficult maintenance, difficult maintenance and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

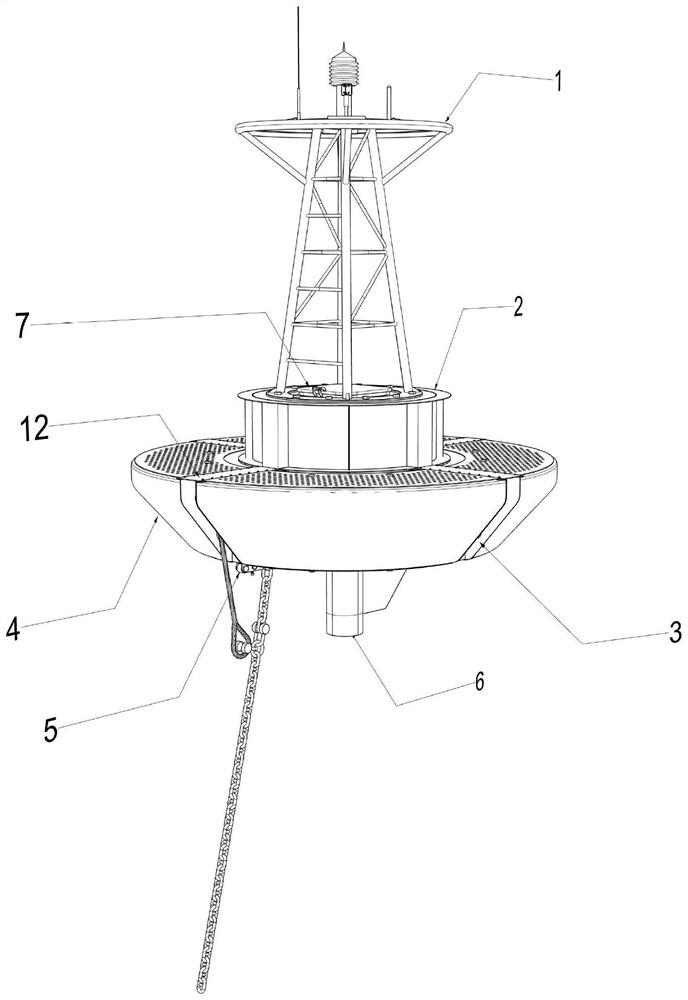

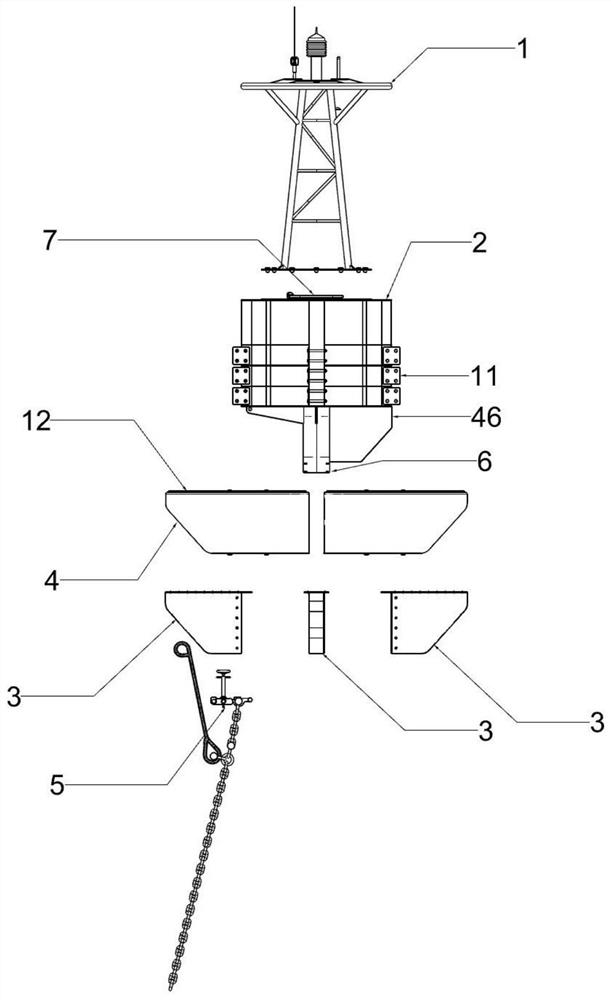

[0059] Such as Figure 1-13 , a multifunctional combined buoy at sea, comprising a main instrument cabin 2 located in the middle of the buoy, a weather observation platform 1 arranged above the main instrument cabin 2, a buoyancy module 4, and a buoy body-mooring separation system 5;

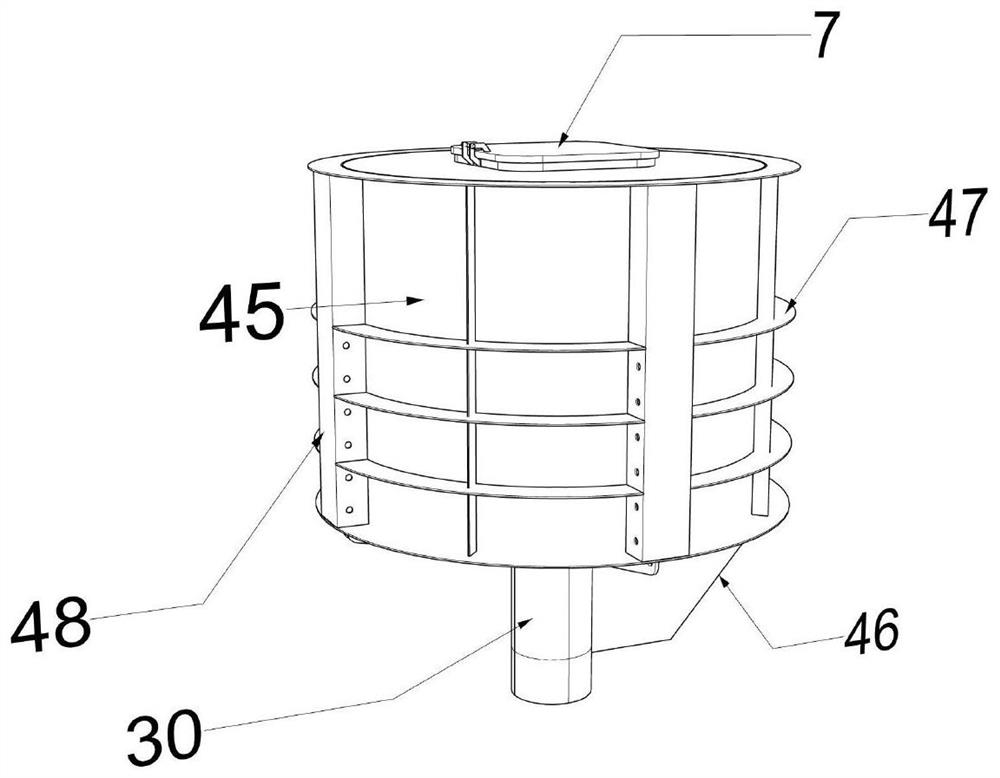

[0060] The main instrument cabin 2 includes a cylindrical main cabin body 45, and the outer side of the main cabin body 45 is provided with multi-layer annular reinforcement ribs 47 and multiple axial reinforcement ribs 48 connected vertically to each annular reinforcement rib 47;

[0061] And a plurality of keel members 3 are radially connected to the axial reinforcing ribs 48 on the outside of the main cabin body 45 through connecting plates 11 and bolts. The middle part of the keel members 3 has an instrument installation well 10 that penetrates up and down. One end is provided with a transverse bollard 9;

[0062] The bottom of the main cabin body 45 is provided with a vertical deflector 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com