A nine-degree-of-freedom robot tightening control method for the assembly of thin-walled large threaded parts

A technology with a control method and a degree of freedom, which is applied to assembly machines, program-controlled manipulators, manipulators, etc., can solve problems such as the impact on the assembly quality of thin-walled large screw parts, high requirements for operator experience, difficult assembly and tightening control methods, etc., to achieve Reduce the occurrence probability of the thread pair stuck phenomenon, ensure the assembly quality, and reduce the effect of the threaded part stuck phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

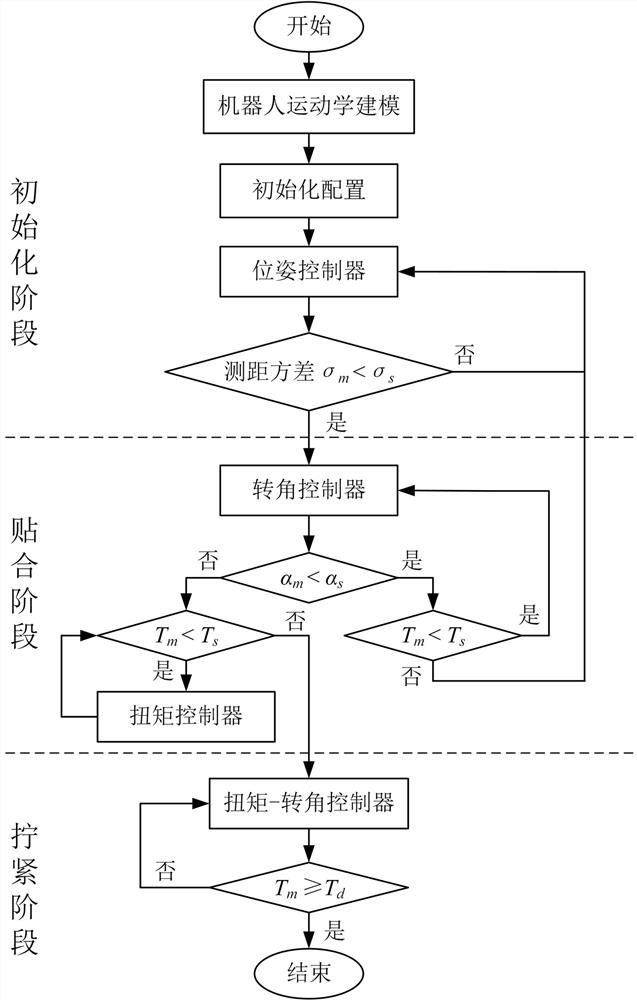

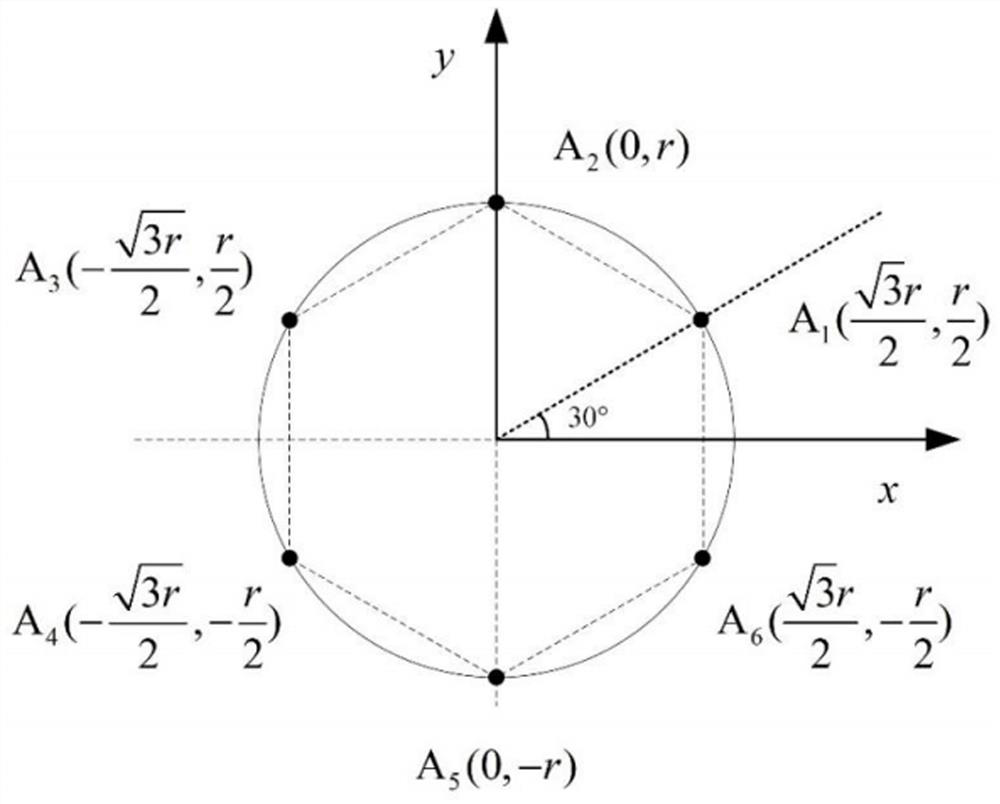

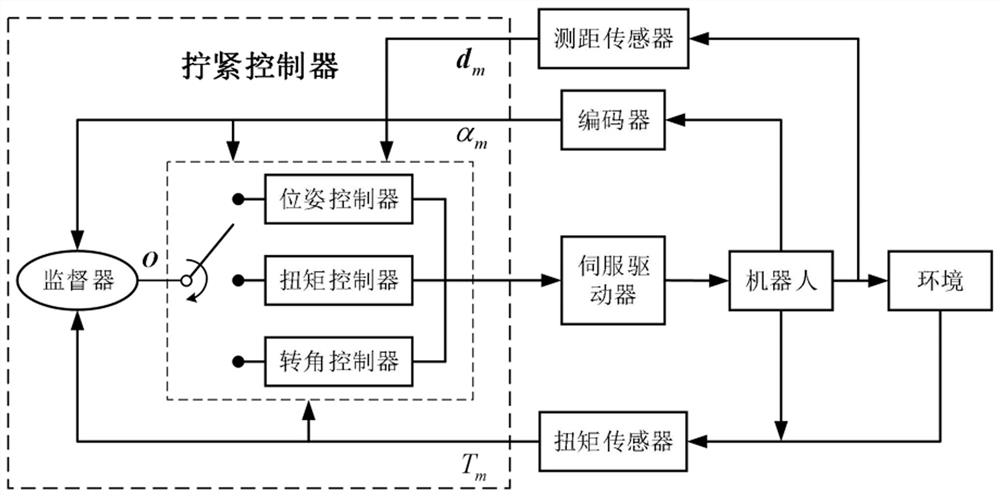

[0068] A nine-degree-of-freedom robot tightening control method for assembling thin-walled large threaded parts. The robot tightening control system includes a tightening controller, a six-degree-of-freedom Stewart platform at the bottom for adjusting the posture of the upper platform tightening mechanism, and a fixed six-degree-of-freedom platform. The three-degree-of-freedom series mechanism on the Stewart platform for tightening control, the rotary motor at the end and fixes the bolts to be assembled, the thin-walled large threaded shell and the linear motor at the front, and the upper and lower platforms are driven by 6 linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com