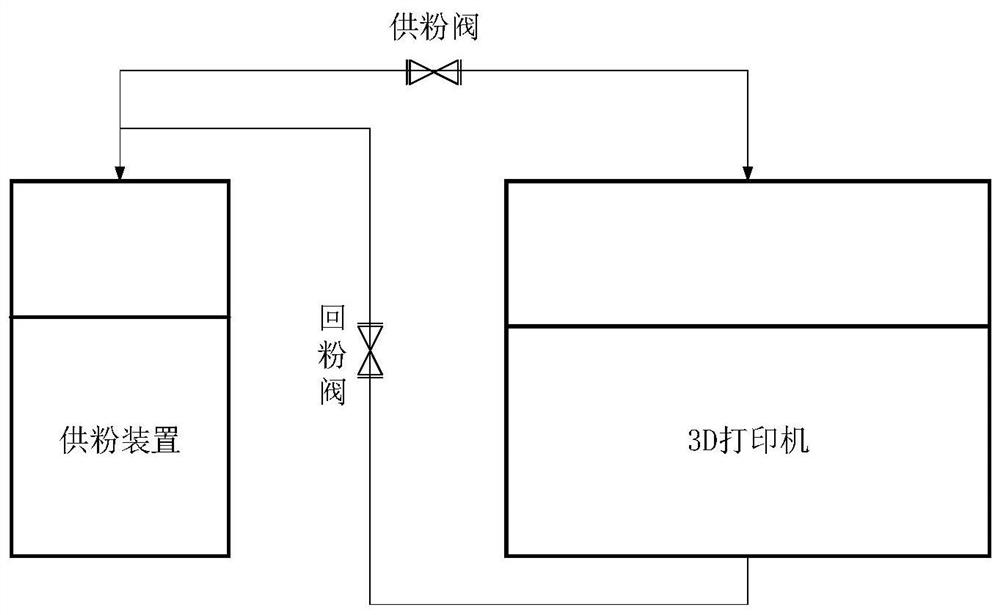

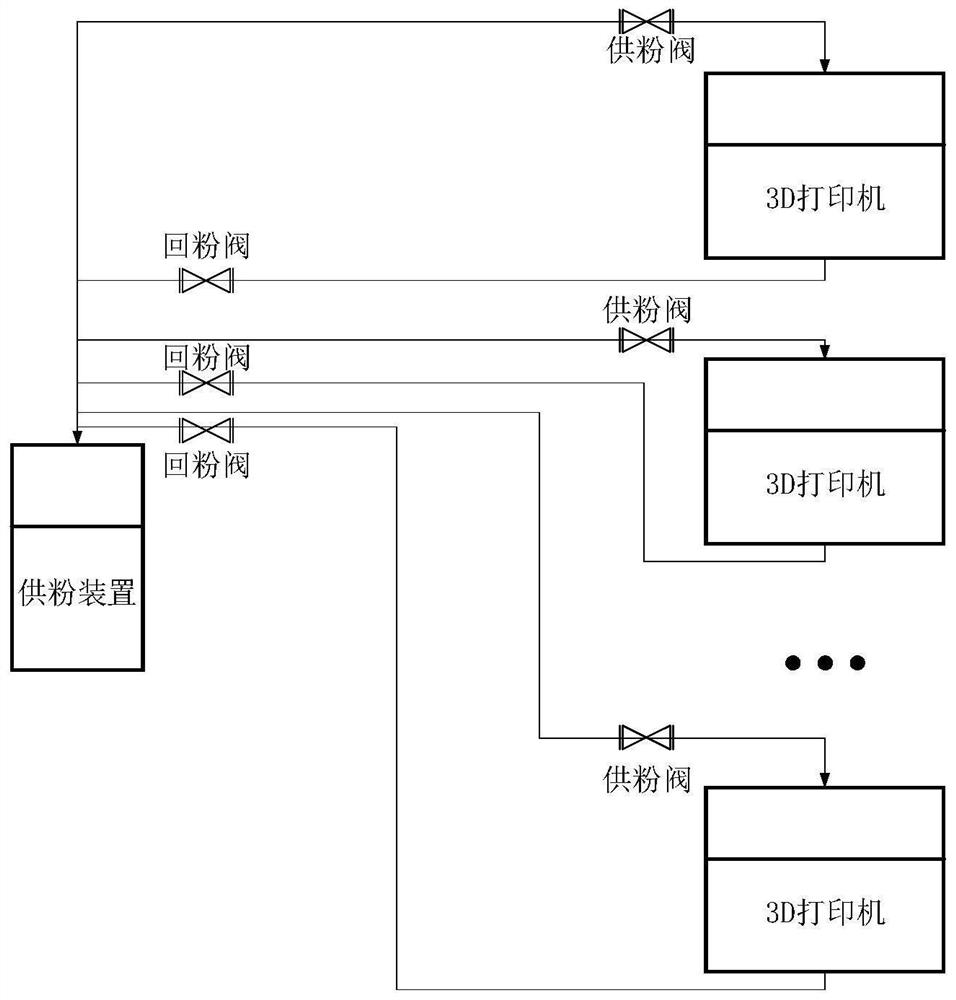

Selective laser melting 3D printing production line system and control method

A laser selective melting and 3D printing technology, applied in the field of additive manufacturing, can solve problems such as production efficiency limitation, reduce production efficiency, and increase equipment cost, and achieve the effect of ensuring consistency, improving production efficiency, and reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] Taking a production line consisting of 5 3D printers and 1 powder supply device as an example, a laser selective melting 3D printing production line and its control method are described in detail.

[0074] (1) The production line starts. This task needs to use No. 1, No. 2, and No. 3 printers for the task, and No. 4 and No. 5 printers are in the space state. Carry out the following tests: the powder supply device detects the powder content in the material preparation cylinder through the material level sensor, and detects the oxygen content inside the device through the oxygen content sensor; No. 1, No. 2, and No. 3 3D printers detect the powder collection cylinder and the powder upper cylinder through the material level sensor The powder content in the printer, the oxygen content inside the printer is detected by the oxygen content sensor, the inert gas inlet pressure and the internal air pressure of the printer are detected by the pressure sensor, the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com