Efficient oil brushing device for wood plates

A kind of wooden board, high-efficiency technology, applied in the field of board processing, can solve the problems of cumbersome process and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

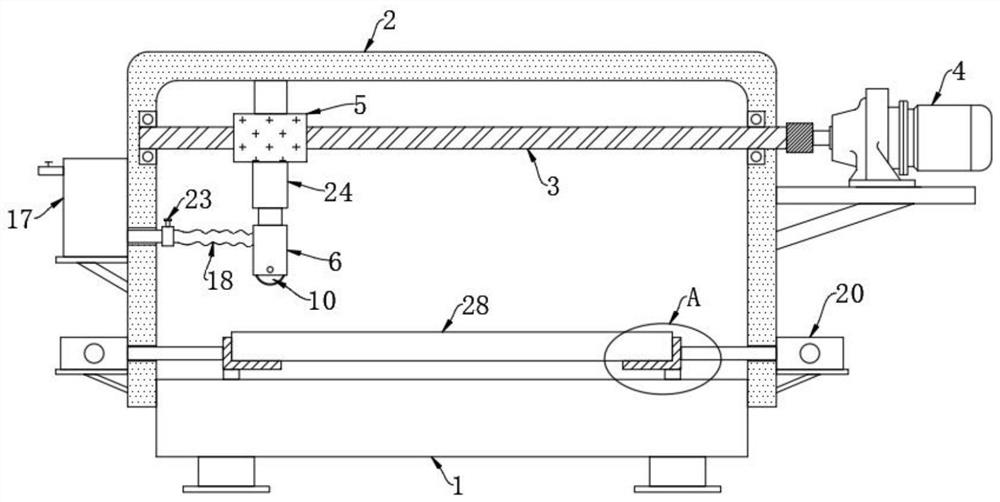

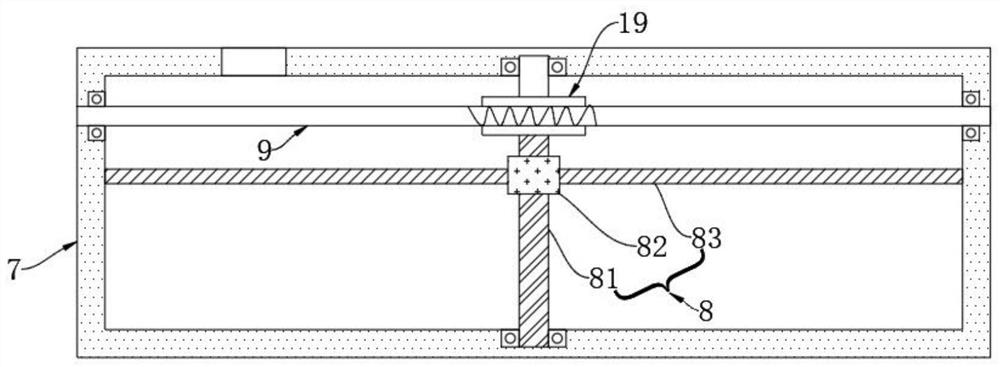

[0033] Such as Figure 1-6 As shown, a high-efficiency brushing device for wooden boards includes a workbench 1, a support 2 is fixedly connected to the workbench 1, and a cylinder 20 is fixedly connected to both side walls of the support 2, and the output end of the cylinder 20 runs through the support 2 And it is fixedly connected with an L-shaped receiving seat 21, through the cooperation of the set cylinder 20 and the L-shaped receiving seat 21, it can press against the wooden board 28 to ensure the stability of the wooden board 28, and the two cylinders 20 can regulate two L-shaped The spacing between the L-shaped receiving seats 21 enables the device to stabilize wooden boards 28 of different lengths, which greatly improves the scope of application of the device. The lower end sidewall of the L-shaped receiving seat 21 is fixedly connected with a slider 22, and the slider 22 Slidingly connected with the workbench 1, the set slider 22 can give the L-shaped receiving seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com