A kind of processing equipment and method of crushed peanuts

A processing equipment and peanut crushing technology, which is applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of unguaranteed particle size, particle uniformity, and low yield of peanut crushing, so as to achieve complete particle size and improve Yield rate, effect of pellet quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

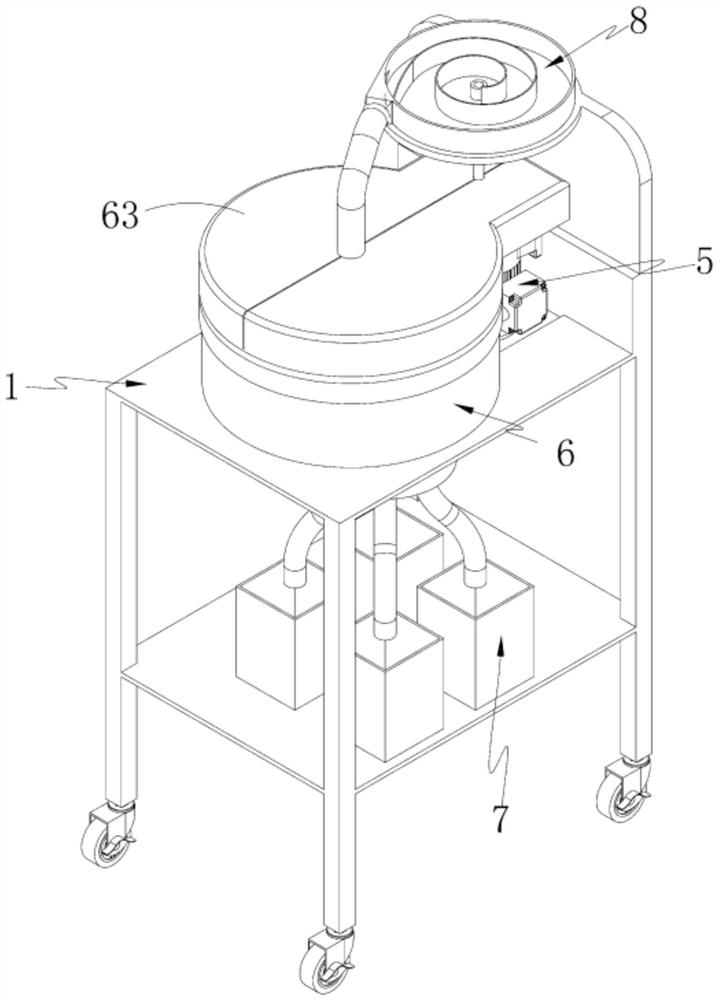

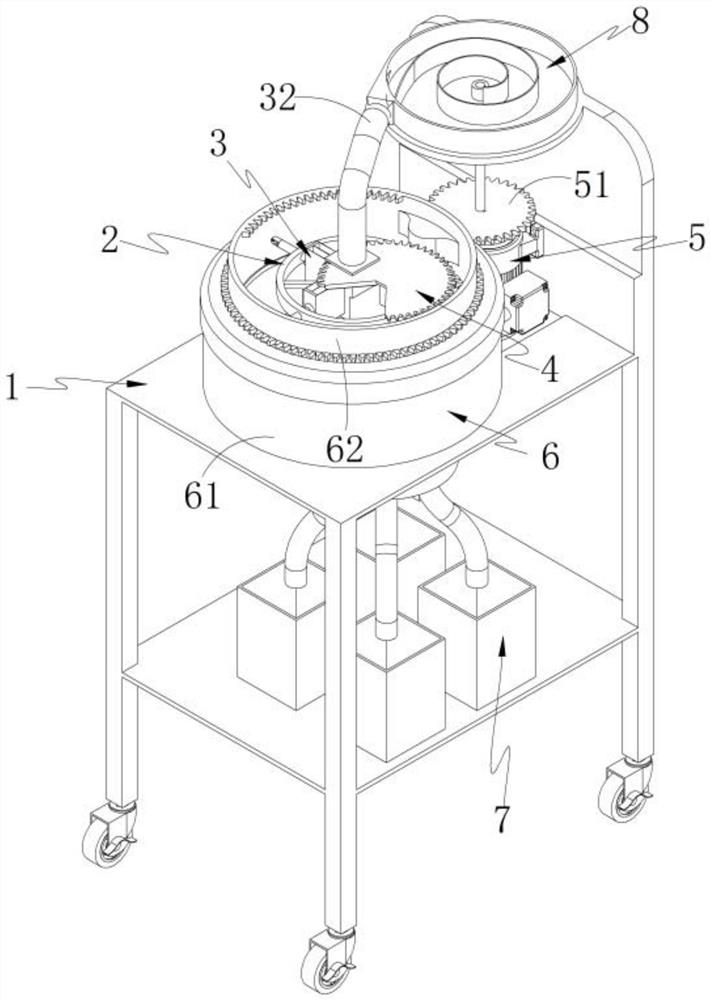

[0047] like Figure 1-2 As shown, a processing equipment for crushed peanuts, including a rack 1, also includes:

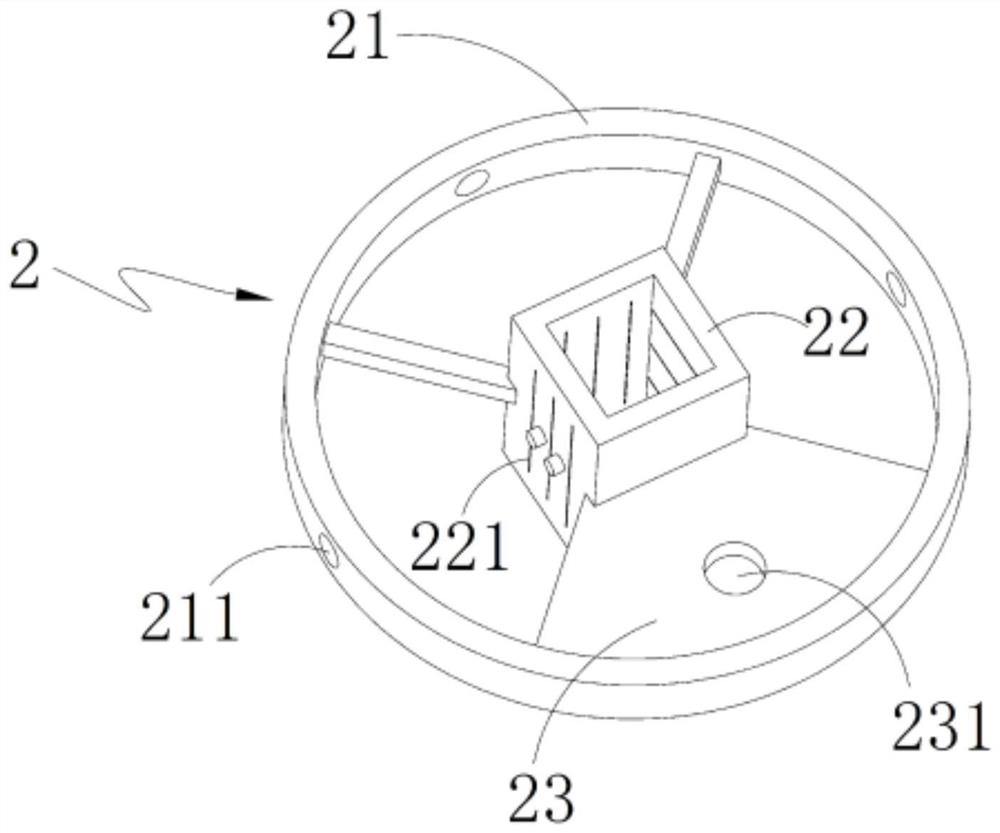

[0048] like image 3 As shown, the tool holder unit 2, the tool holder unit 2 is arranged on the frame 1, which includes an annular connecting frame 21, a tool holder 22 arranged on the annular connecting frame 21, and the tool holder 22 is hollow design , its three sides are respectively provided with guide grooves 221, and the other side is provided with a connecting plate 23 connecting the tool holder 22 and the annular connecting frame 21, the connecting plate 23 is provided with a through hole a231; the annular connection The frame 21 is provided with three guide holes 211 in the circumferential direction;

[0049] like Figure 4 As shown, three cutting knives 3 are matched with the guide holes 211, the cutting knives 3 include a set of cutting edges 31 and a cutting rod 32 connected with a set of cutting edges 31, the set of cutting edges 31 and the guide...

Embodiment 2

[0070] like Figure 12-16 As shown in the figure, the same or corresponding parts as in the first embodiment are marked with the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment The point is:

[0071] Among them, such as Figure 12-13 As shown, the drive unit 5 drives the feeding control unit 4 to rotate, and after the discharge opening 432 on the feeding plate 43 turns over the tool rest 22, the bottom of the tool rest 22 is closed. At this time, the feeding opening 422 on the feeding plate 42 is closed. Connected with the tool holder 22, so that the peanuts enter the tool holder 22 through the discharge channel 82 of the sorting unit 8;

[0072] Among them, such as Figure 14-15 As shown in the figure, the feeding control unit 4 continues to rotate, and the peanuts outside the upper end face of the k...

Embodiment 3

[0076] The present embodiment provides a processing method of ground peanuts, comprising the following steps:

[0077] As an improvement, the drive unit 5 drives the annular control disc 62 to rotate, the annular control disc 62 drives the feed control unit 4 to rotate, and the discharge opening 432 on the feed plate 43 turns over the tool rest 22, so that the bottom of the tool rest 22 is closed, At this time, the feeding opening 422 on the dividing plate 42 is communicated with the knife rest 22, so that the peanuts enter the knife rest 22 through the discharge channel 82 of the sorting unit 8, the feeding control unit 4 continues to rotate, and the feeding control unit 4 continues to rotate. The peanuts outside the upper end face of 22 are placed on the dividing plate 42; the guide block 624 pushes the three cutting knives 3 in turn, so that the peanuts are chopped horizontally and vertically in turn; Realize delivery.

[0078] Preferably, after the discharging is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com