Batching device for spicy sauce production

A technology of spicy sauce and material box, which is applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., which can solve the problem of unhealthy and hygienic maintenance and cleaning of sauces, inability to sieve raw materials for pretreatment, and poor quality of sauces and other issues to achieve the effect of ensuring health, good quality and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

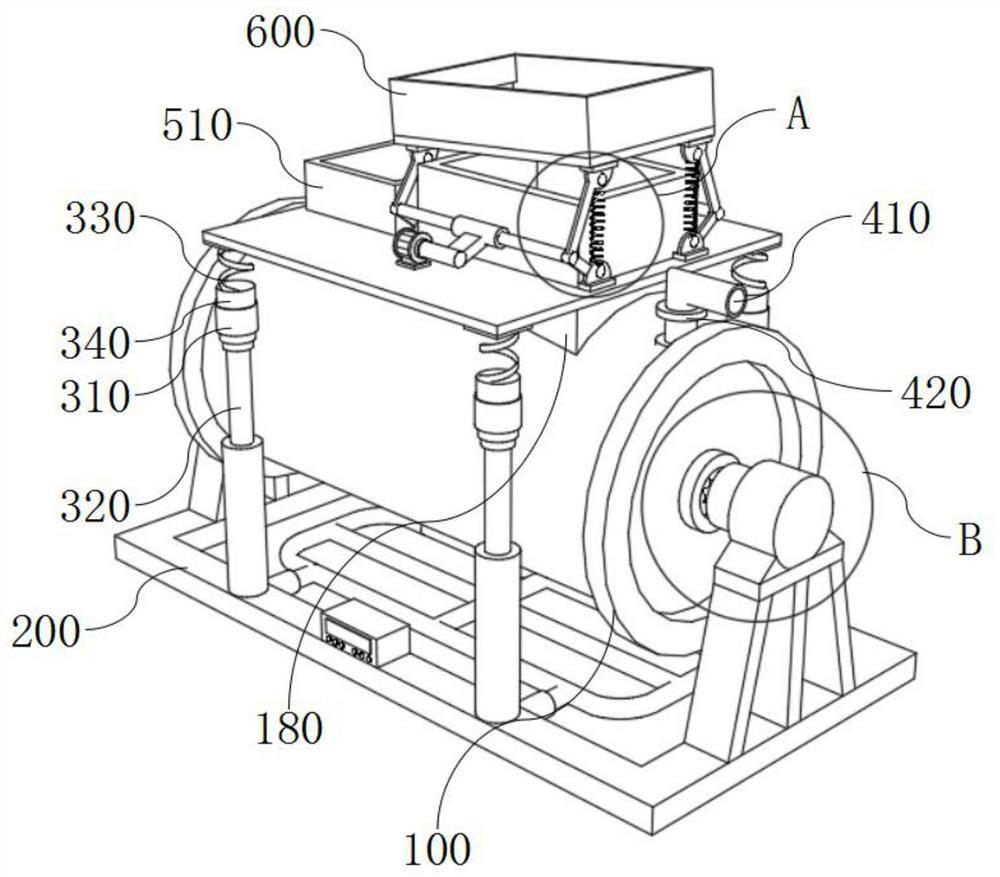

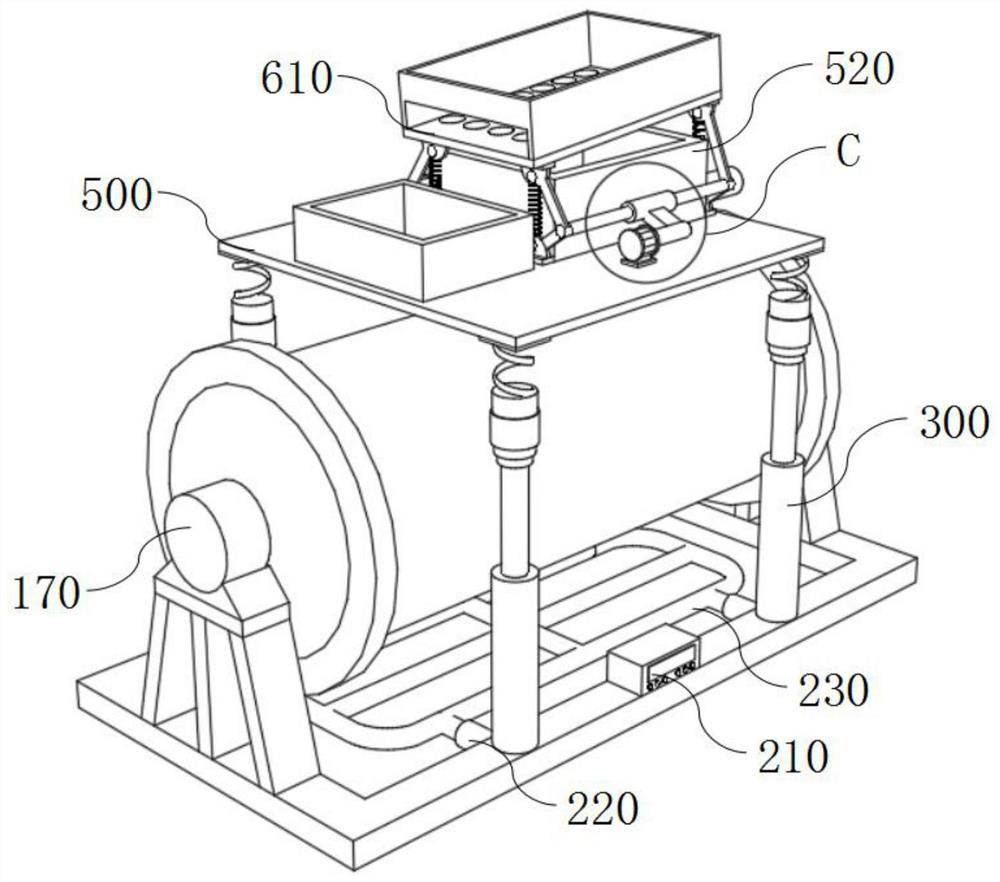

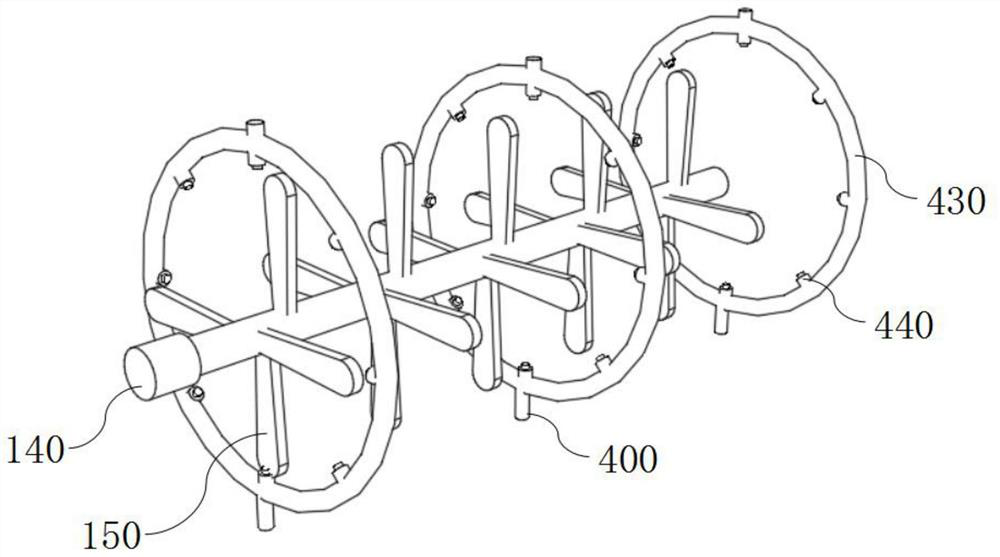

[0030] see Figure 1-6As shown, the present invention is a batching device for spicy sauce production, including a housing 100, a base 200, a bearing column 300, a water injection mechanism 400, a screening mechanism 500 and a feeding frame 600, and the housing 100 includes a housing body, a supporting column 110 and an input frame 600. The material inlet 180, the base 200 includes the base body, the bearing column 300 includes the bearing column body and the shock absorbing spring 330, the water injection mechanism 400 includes the water injection mechanism body and the water inlet valve 420, and the screening mechanism 500 includes the screening mechanism body, the discharge frame 520 and the transmission pipe 570, the feeding frame 600 includes a first connecting bar 630, a second fixing block 640 and a second connecting bar 650, one end of several support columns 110 and one end of the bearing column body are welded to the upper surface of the base body, and one end of some...

Embodiment 2

[0038] see Figure 1-6 As shown, the present invention is a batching device for the production of spicy sauce, wherein the stirring motor 130 and the screening motor 530 are both YB3-100L2-4, and the carrying cylinder 310 is SC63*25. When the staff is in use, The stirring motor 130 drives the stirring blade 150 to stir the sauce, so that the sauce is fully mixed, the rotating power of the screening motor 530 is improved through the transmission tube 570 and the bearing tube 560, the vibration frequency of the screening is accelerated, and the output efficiency of the screening motor 530 can be adjusted , to control the vibration frequency, the screening plate 610 is placed obliquely, the first connecting bar 630 and the second connecting bar 650 drive the transmission pipe 570 to perform the feeding movement, thus the screening plate 610 drives the up and down vibration, and the connecting spring 660 increases the vibration frequency. The heater 220 controls the heating tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com