Self-adaptive lattice type 3D printing helmet buffer layer and manufacturing method thereof

A 3D printing, self-adaptive technology, applied in helmets, helmet caps, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

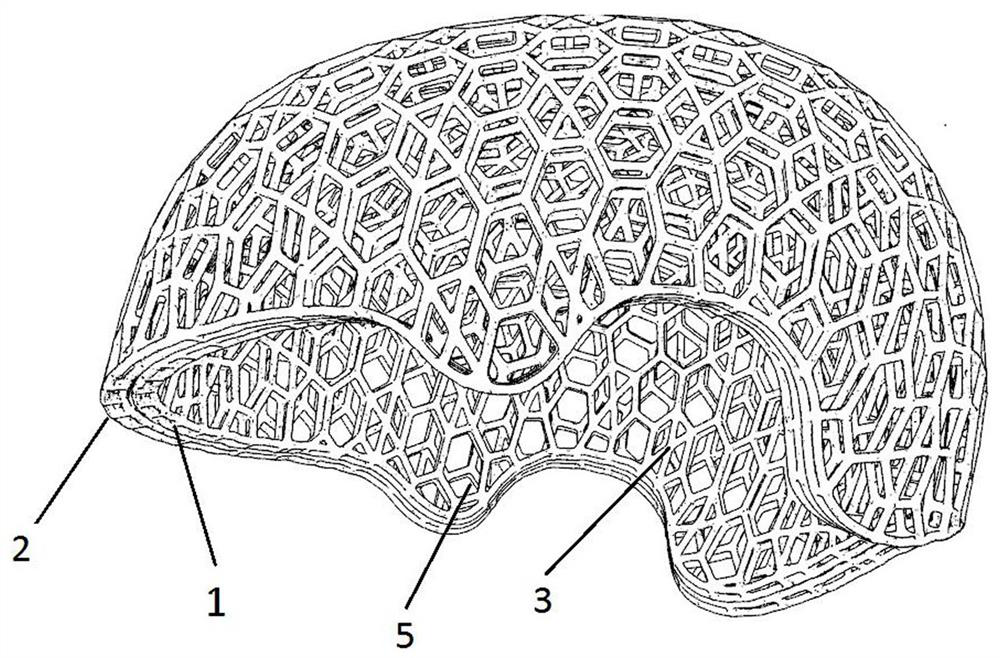

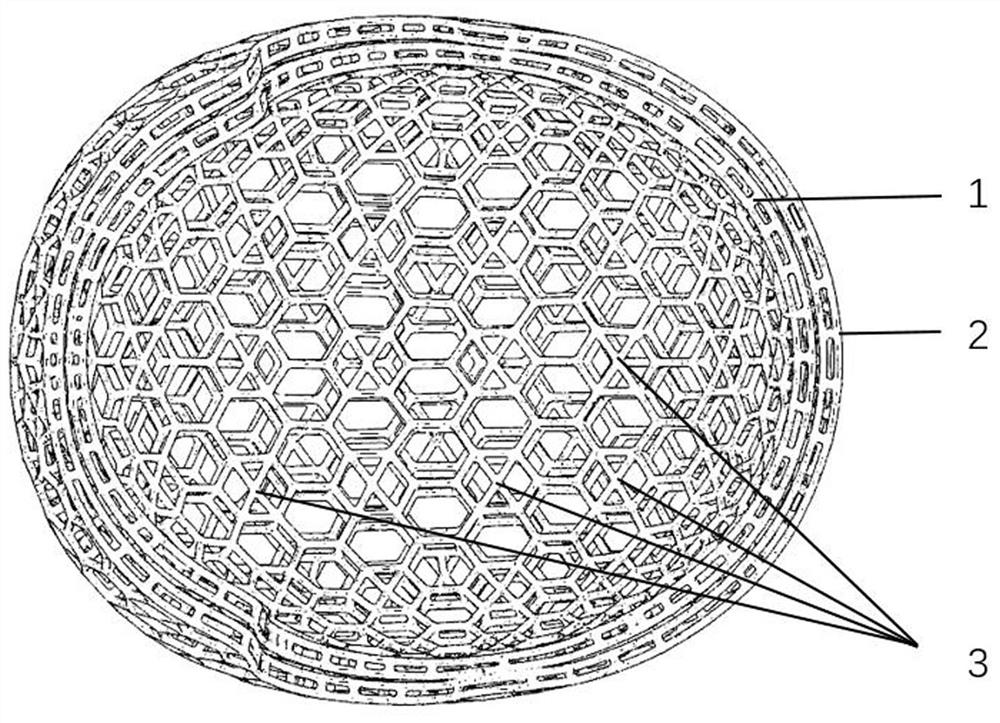

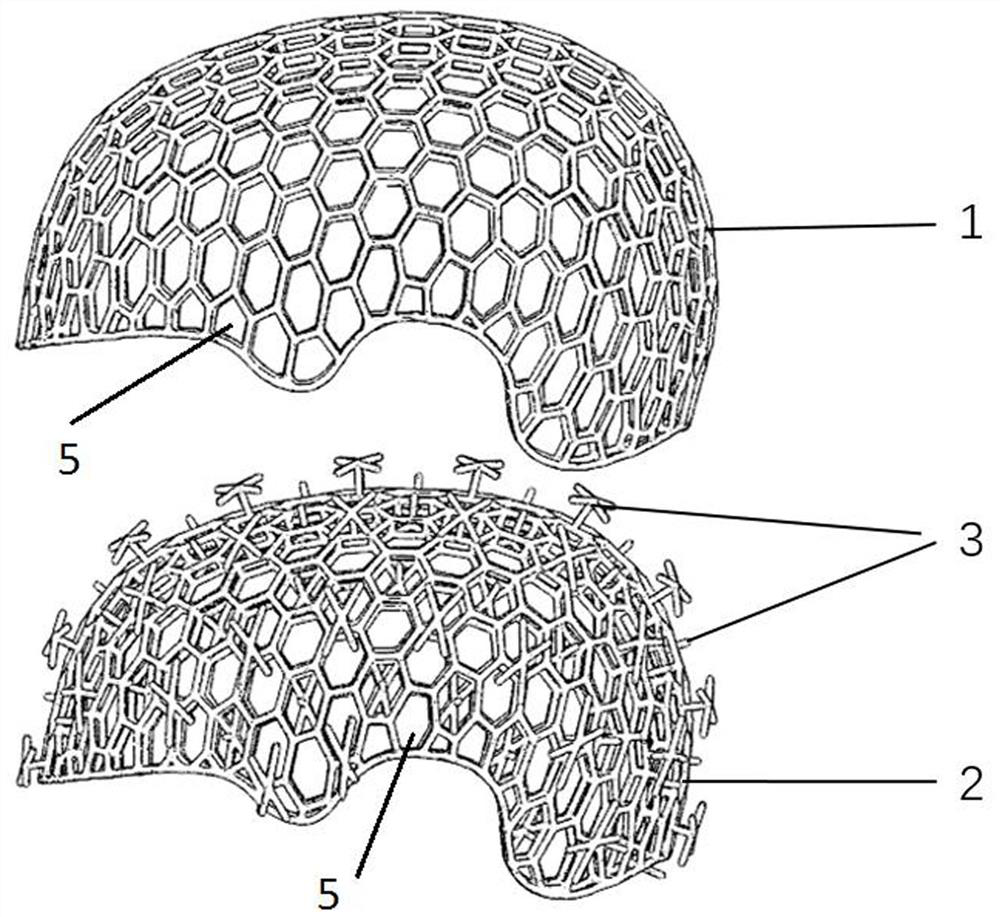

[0037] Such as Figure 1~Figure 3 As shown, this embodiment provides an adaptive lattice-type 3D printed helmet buffer layer, including an inner truss 1 and an outer truss 2, the outer truss 2 is arranged outside the inner truss 1, and is connected by a support unit , the stiffness of the support unit is less than that of the outer truss 2 and its inner truss 1, and there is a gap between the inner truss 1 and the outer truss 2 that allows them to slide tangentially relative to each other.

[0038] In this embodiment, there is a gap between the outer truss 2 and the inner truss 1, which provides conditions for the relative tangential slip of the two, and the stiffness of the support unit is smaller than the stiffness of the outer truss 2 and the inner truss 1, so that the support Elements are more prone to deformation. When the buffer layer is impacted by the outside world, the impact force can be divided into the normal force perpendicular to the contact surface and the tang...

Embodiment 2

[0047] This embodiment also provides a method for making an adaptive lattice type 3D printing helmet cushioning layer, comprising the following steps:

[0048] 1) Use design software to establish a digital model of the buffer layer;

[0049] 2) Import the digital model into a 3D printer for printing.

[0050] In step 1), digital models of the forehead surface 7, the top surface of the head 8, the left side 9, the right side 10, and the back side of the brain 115 were respectively established; in step 2), the forehead surface 7, the top surface of the head 8, and the left side were printed respectively. Side 9, the right side 10, and the back side of the head 115, after the printing is completed, the adjacent parts are bonded.

[0051] The design process is as follows:

[0052] (1) Design the inner truss 1: Firstly, the inner head shape surface is established according to the size of the user’s head shape obtained by surveying and mapping. The inner hexagonal mesh surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com