Auxiliary system for crop picking in facility agriculture environment and control method

A facility agriculture and auxiliary system technology, applied in agriculture, picking machines, program-controlled manipulators, etc., can solve the problems of reducing fruit and vegetable picking efficiency, uneven spatial distribution of target fruits and vegetables, and inaccessibility of target fruits and vegetables, so as to save manpower and improve Stability, the effect of expanding the picking range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

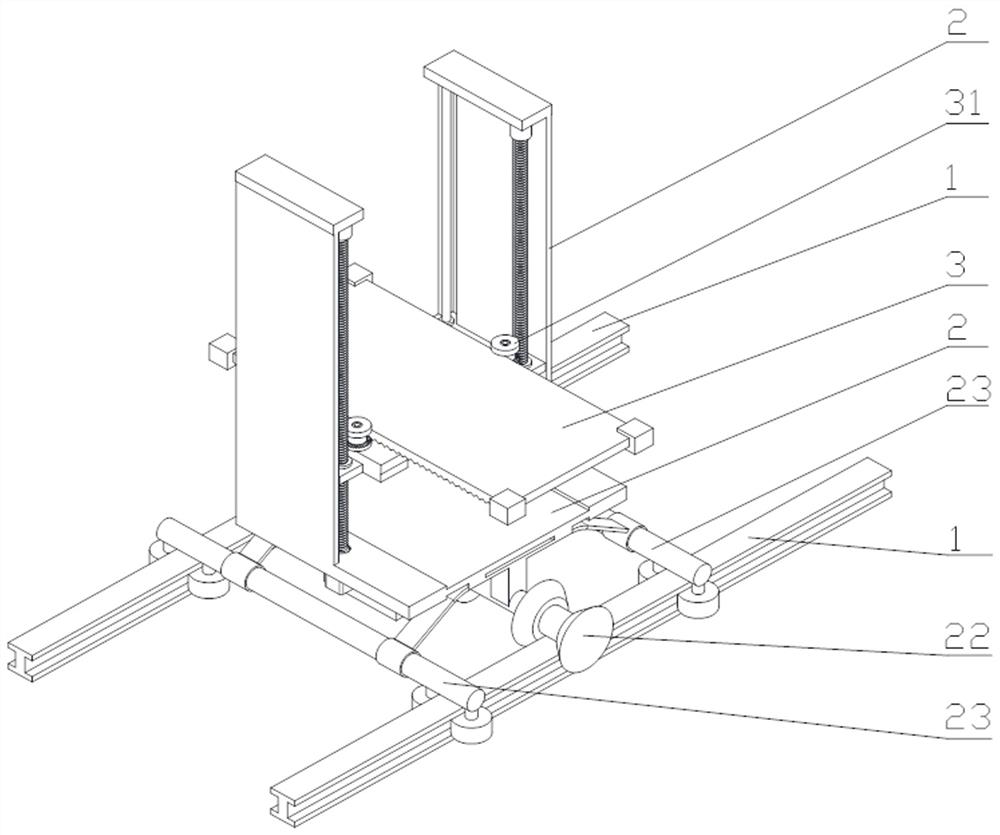

[0049] The auxiliary system for picking in the facility agricultural environment, such as figure 1 As shown, it includes a guide rail 1 , a chassis mechanism 2 and a mobile platform 3 .

[0050] The cross section of the guide rail 1 is I-shaped, the groove is in the horizontal direction, and is fixed on the ground, and the two guide rails are parallel to each other.

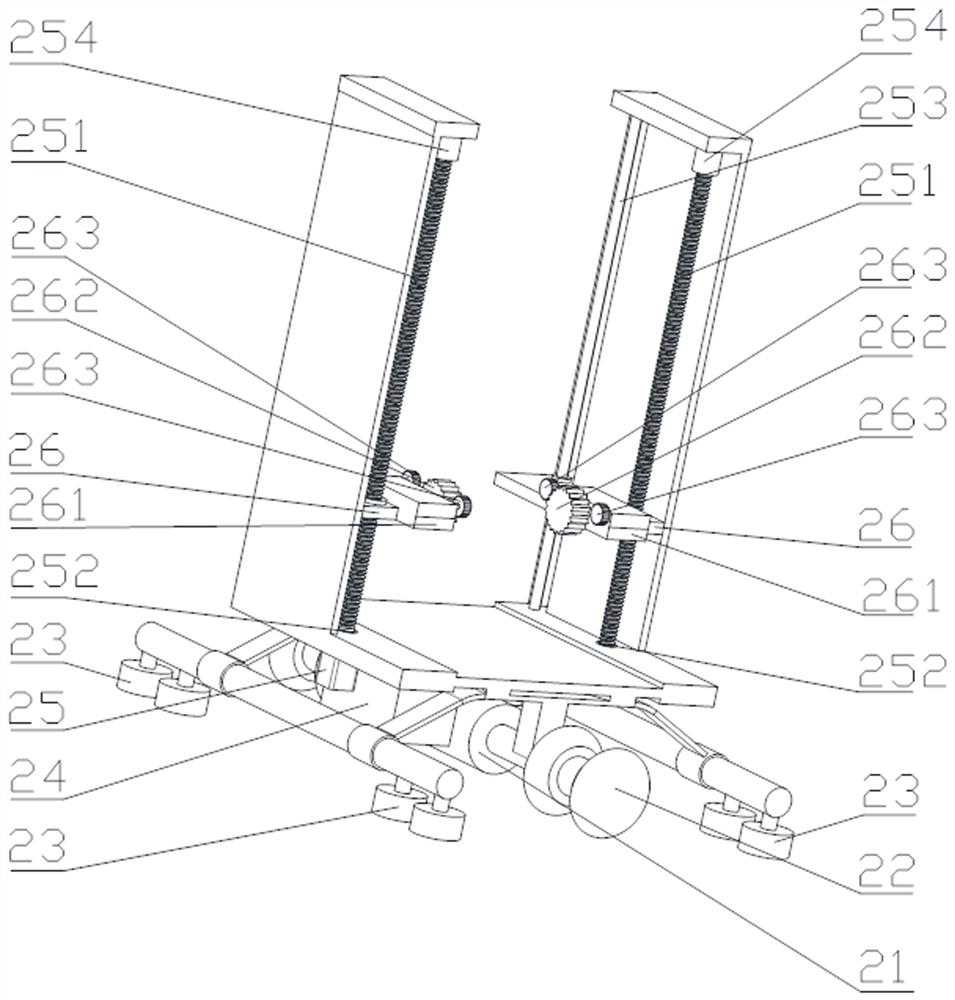

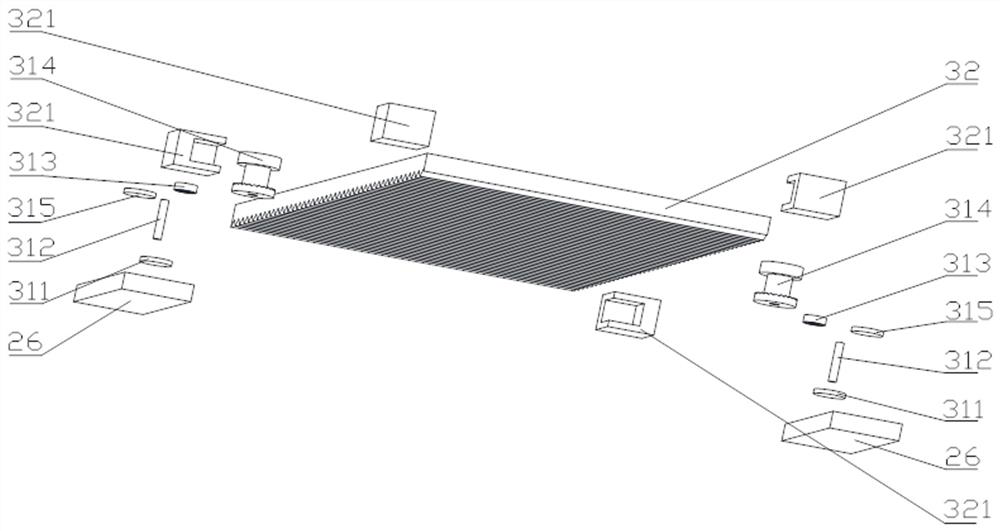

[0051] The chassis mechanism includes a support base plate and a U-shaped frame formed by vertical baffles on both sides of the support base plate. The chassis mechanism 2 is the carrier that realizes the movement of the system parallel to the crop direction. It is the system that normally runs on the guide rail 1. key structures such as figure 2 shown. The chassis mechanism 2 also includes: a DC motor 21 , a driving wheel 22 , a driven wheel 23 , a control system 24 , a stepping motor 25 , and a stage assembly 26 . The top of the stepper motor 25 includes a screw rod 251, a bearing 252, a guide rod 253, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com