Aluminum square tube mounting structure with externally-hung decorative plates

A technology for installing structures and decorative panels, which is applied in building components, building structures, sustainable buildings, etc., and can solve problems such as deformation of aluminum squares, labor-intensive, and normal business operations in public places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

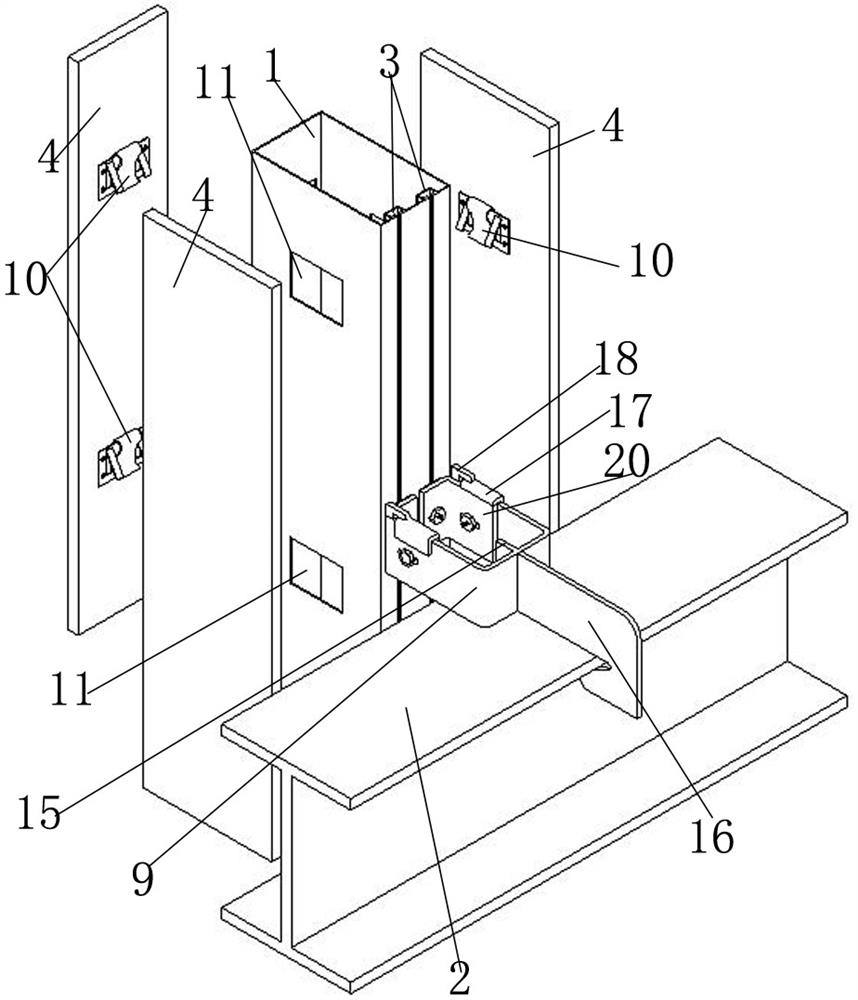

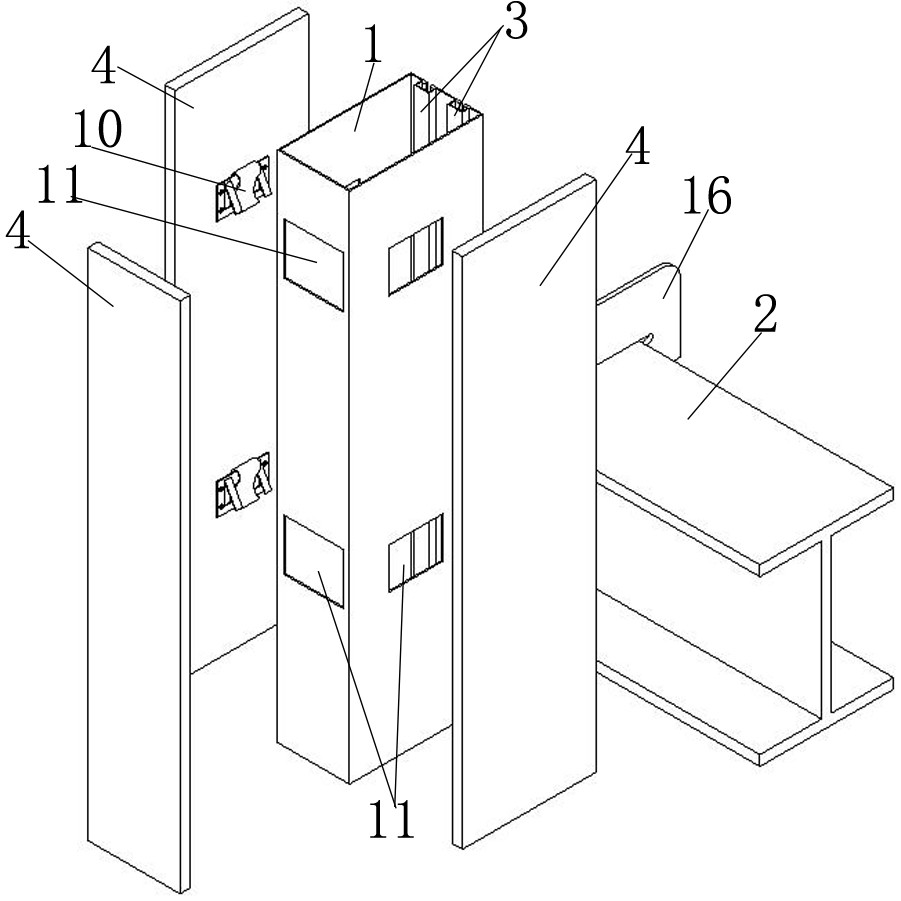

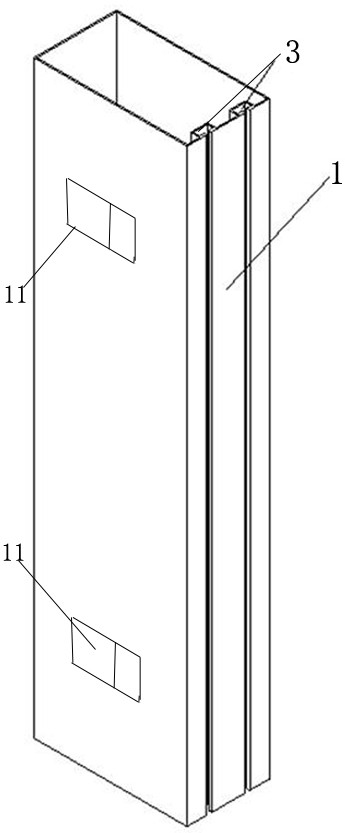

[0035] refer to Figure 1-Figure 15 , the installation structure of an aluminum square with an external decorative board according to the present invention will be described in detail.

[0036] An aluminum square pass installation structure provided with external decorative panels, such as Figure 1 to Figure 5 As shown, including aluminum square pass 1 and steel member 2, such as figure 1 , figure 2 and image 3 As shown, one side of the aluminum square duct 1 is embedded with two parallel bolt installation and fixing grooves 3 along its own length direction, and an external decorative plate 4 is detachably installed on at least one side of the aluminum square duct 1 , also includes two U-shaped corner codes that are interlocked to form a rectangular cylindrical structure, such as Figure 4 and Figure 5 As shown, and the width of the formed rectangular tubular structure is less than or equal to the width of the side wall of the connected U-shaped corner code of the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com