Automobile armrest edge covering equipment

A car armrest and hemming technology, applied in the mechanical field, can solve problems such as skin wrinkles and products that do not meet processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

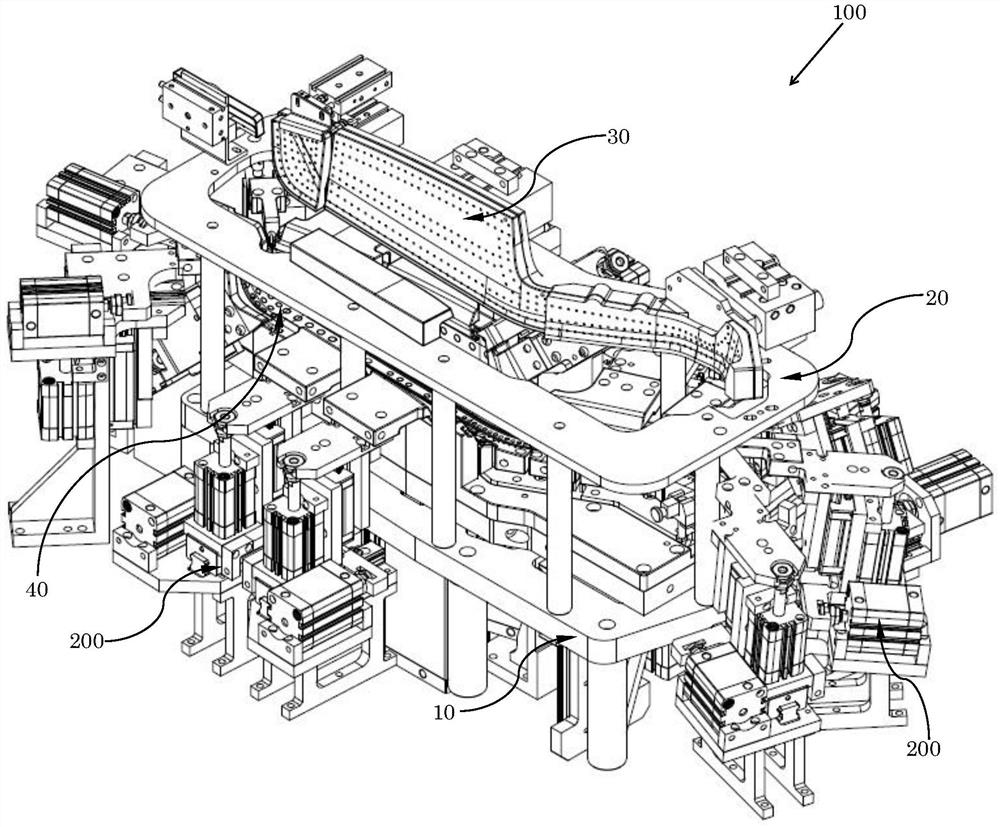

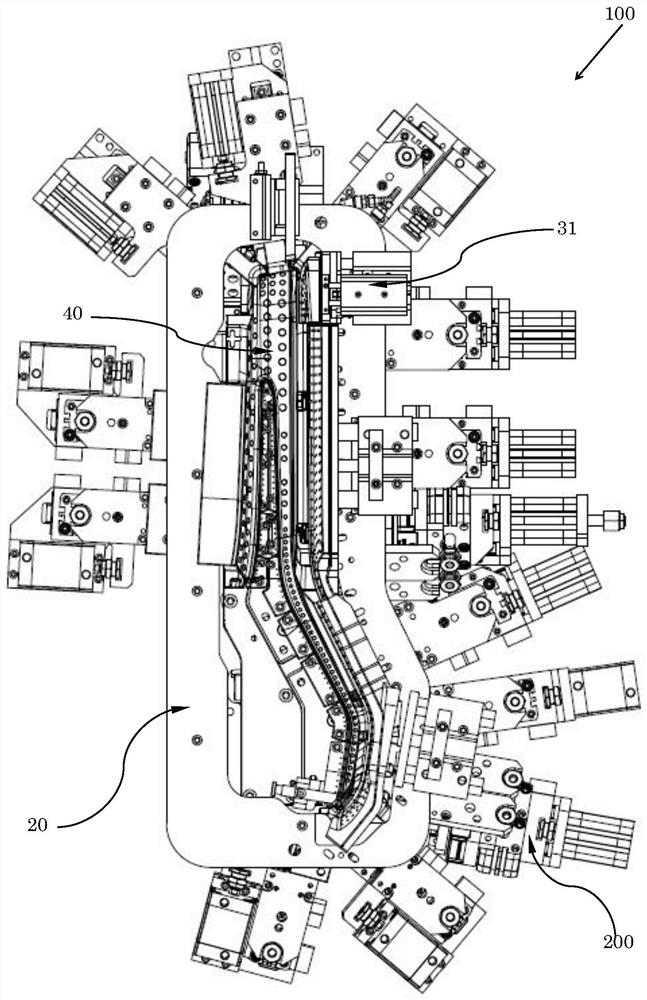

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically elaborate on the automobile armrest hemming device of the present invention in conjunction with the accompanying drawings.

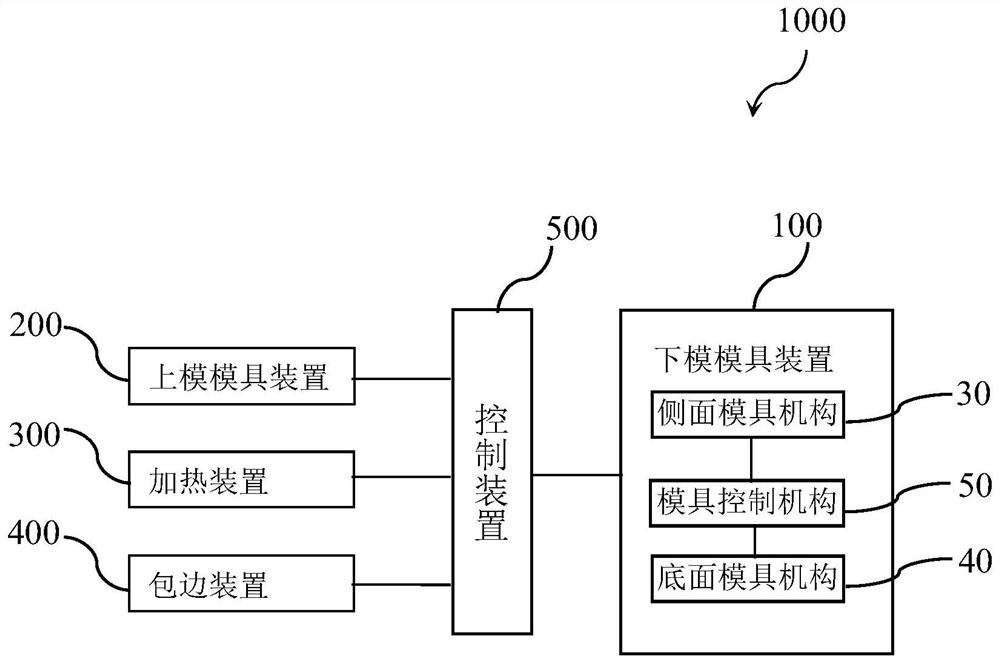

[0031] figure 1 It is a structural block diagram of an automobile armrest hemming device in an embodiment of the present invention.

[0032] Such as figure 1 As shown, the automobile armrest hemming equipment 1000 in the present embodiment is used for pasting the skin and hemming the automobile armrest skeleton semi-finished product 1, including: a support device (not shown in the figure), a lower mold device 100, an upper mold mold The device 200 , the heating device 300 , the hemming device 400 and the control device 500 . The control device 500 is used to control the operation of the lower mold device 100 , the upper mold device 200 , the heating device 300 and the hemmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com