Sheet curling device

A curling device and sheet technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of wasting time, wasting labor resources, and not easy to bend the sheet, achieving good results, avoiding sheet adhesion, and easy rolling edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

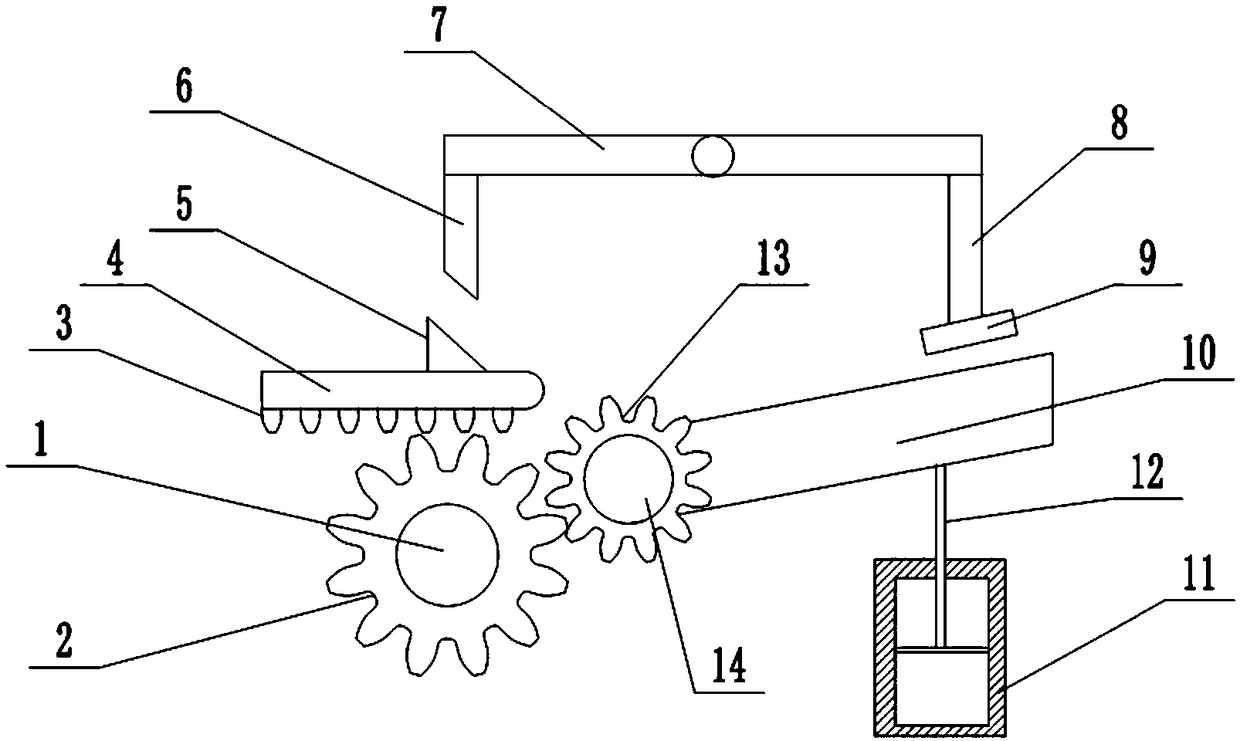

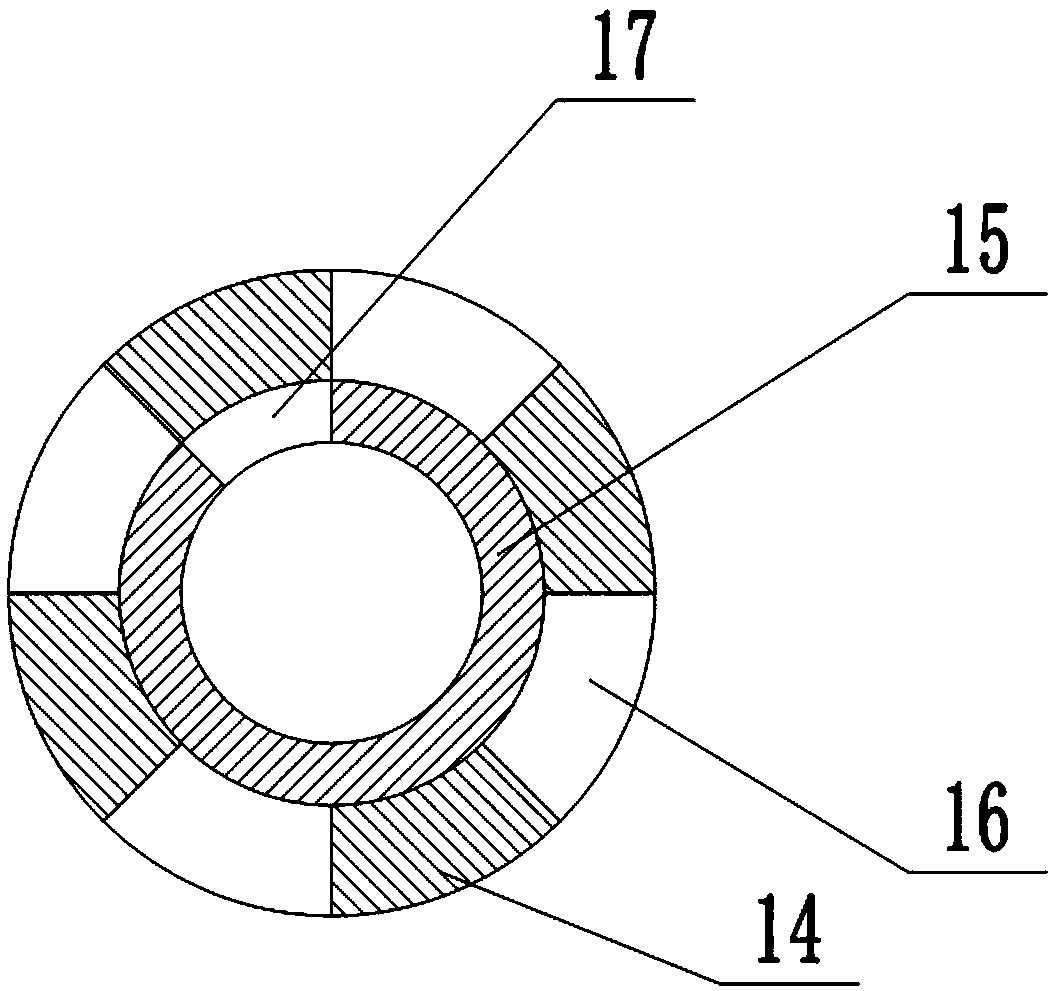

[0022] The reference signs in the drawings of the description include: rotating shaft 1, first gear 2, rack 3, bending punch 4, wedge 5, wedge bar 6, cross bar 7, pressing bar 8, pressing plate 9, supporting plate 10 , Piston barrel 11, piston rod 12, second gear 13, outer cylinder 14, inner cylinder 15, first through hole 16, second through hole 17.

[0023] like figure 1 As shown, the plate hemming device includes a frame, and the frame is provided with a bending part, a fixing part and a driving part. The bending part includes a bending punch 4 that is slidably connected to the frame horizontally. The right end is semicircular, and the upper surface of the bending punch 4 is fixed with a wedge 5 with a wedge surface facing the upper right, and the lower surface of the bending punch 4 is connected with a rack 3 .

[0024] The driving part is located below the bending punch 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com