Teaching board self-wrapping automatic assembly line and method

An assembly line and teaching board technology, applied in the field of teaching boards, can solve problems such as difficulty in ensuring consistent product quality, inability to guarantee writing continuity, and low efficiency, and achieve the effects of reduced labor costs, simple and easy operation, and reduced labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Such as Figure 1-8 As shown, Embodiment 1 of the present disclosure provides an automatic assembly line for teaching board self-hemming, including a feeding area, a gluing area, an extrusion bonding area, a bending forming area, a shaping area, a cutting area and a finished product stacking area.

[0055] The function and working principle of each area will be explained in detail as follows:

[0056] Feeding area: There is a feeding mechanism for feeding and transferring the panels, backplanes and interlayers; raw materials are placed in this area, and the raw materials mainly include three raw materials for panels, backplanes and interlayers, which is the starting end of the assembly line;

[0057] Gluing area: a gluing mechanism is provided, and the gluing mechanisms are respectively arranged on the side close to the back plate and the panel close to the interlayer. The snowfall plate described in this embodiment is composed of three parts: It is made of glue, and t...

Embodiment 2

[0083] Such as Figure 9 As shown, Embodiment 2 of the present disclosure provides a self-edging method for teaching boards, comprising the following steps:

[0084] S101: Put the raw materials into the corresponding position in the feeding area: the back panel is on top, the interlayer is in the middle, and the panel is on the bottom;

[0085] S102: Pull the backboard and the panel through the glue application area, so that the glue is evenly applied to the inner surface of the panel and the backboard;

[0086] S103: pulling the interlayer, so that the interlayer meets the S102 panel and the back panel at the front end of the extrusion bonding area, and simultaneously feeds into the extrusion bonding area;

[0087] S104: Waiting for the process of extruding the bonding area to end. At this time, if the panel, back panel and interlayer are not well bonded, the glue ratio and reaction time should be adjusted in time;

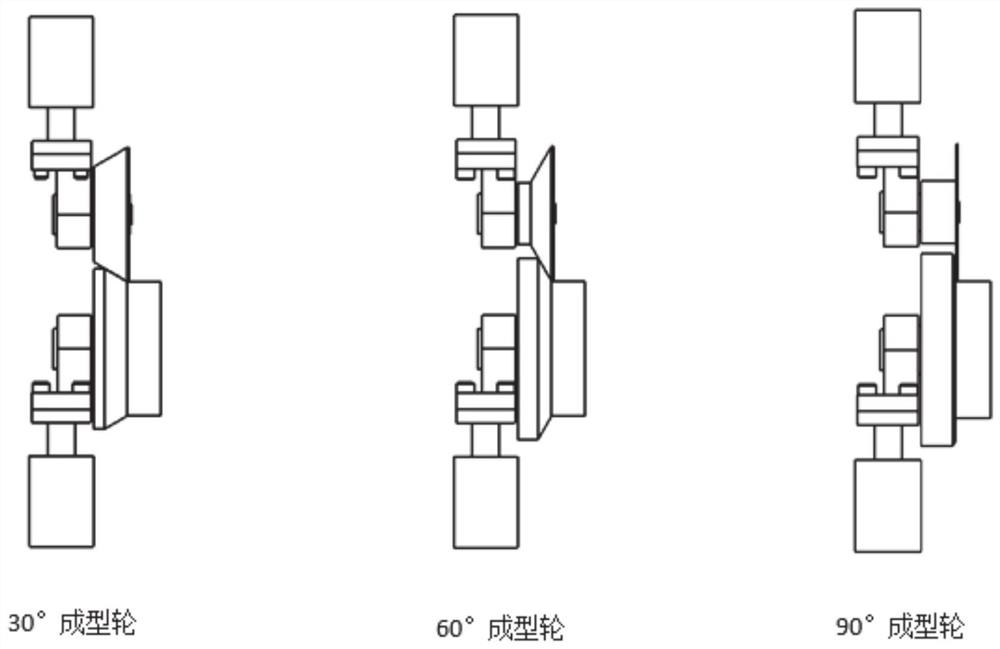

[0088] S105: Adjust the height of the forming wheel so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com