Displacement balance control device for movable pressing plate on cold press and control method of displacement balance control device

A movable platen and balance control technology, which is applied in veneer presses, plywood presses, manufacturing tools, etc., can solve problems affecting cold pressing effects, hydraulic plunger displacement difference, upper movable platen tilt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

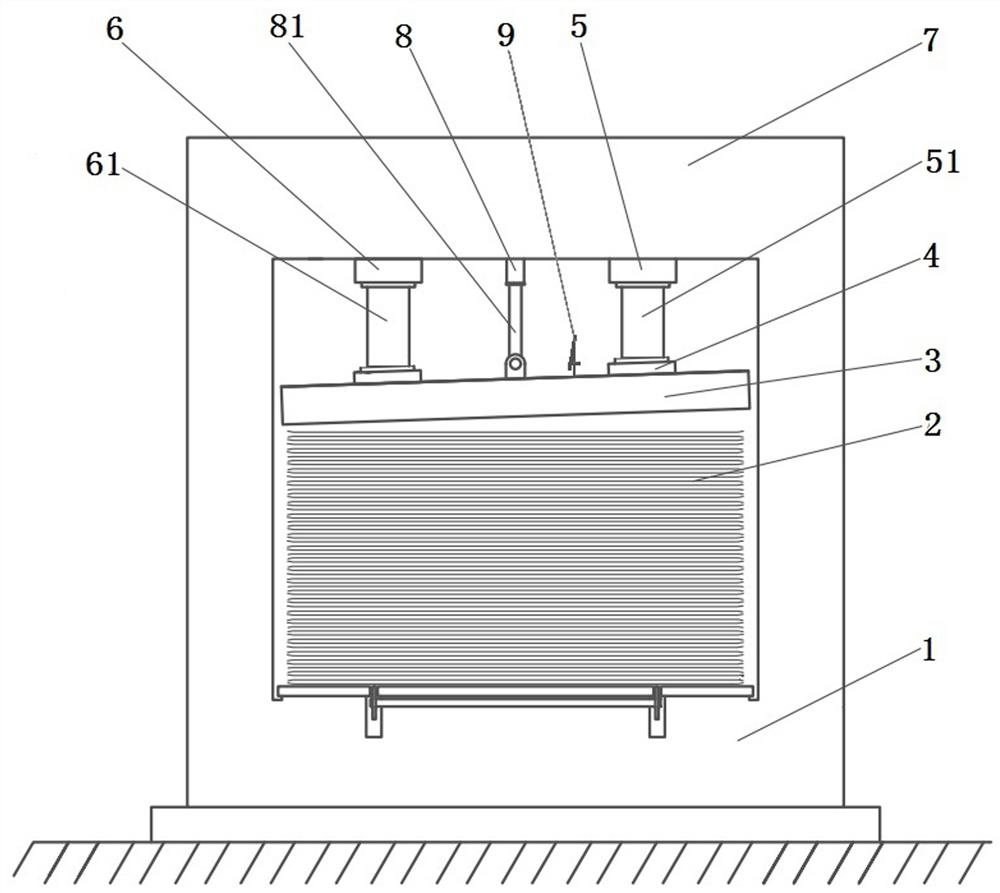

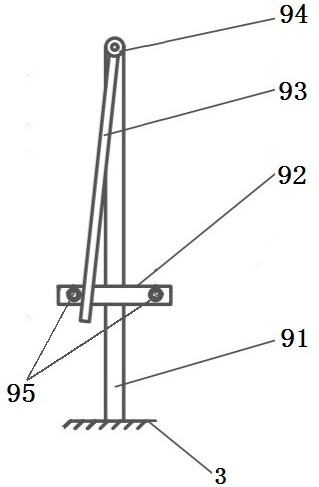

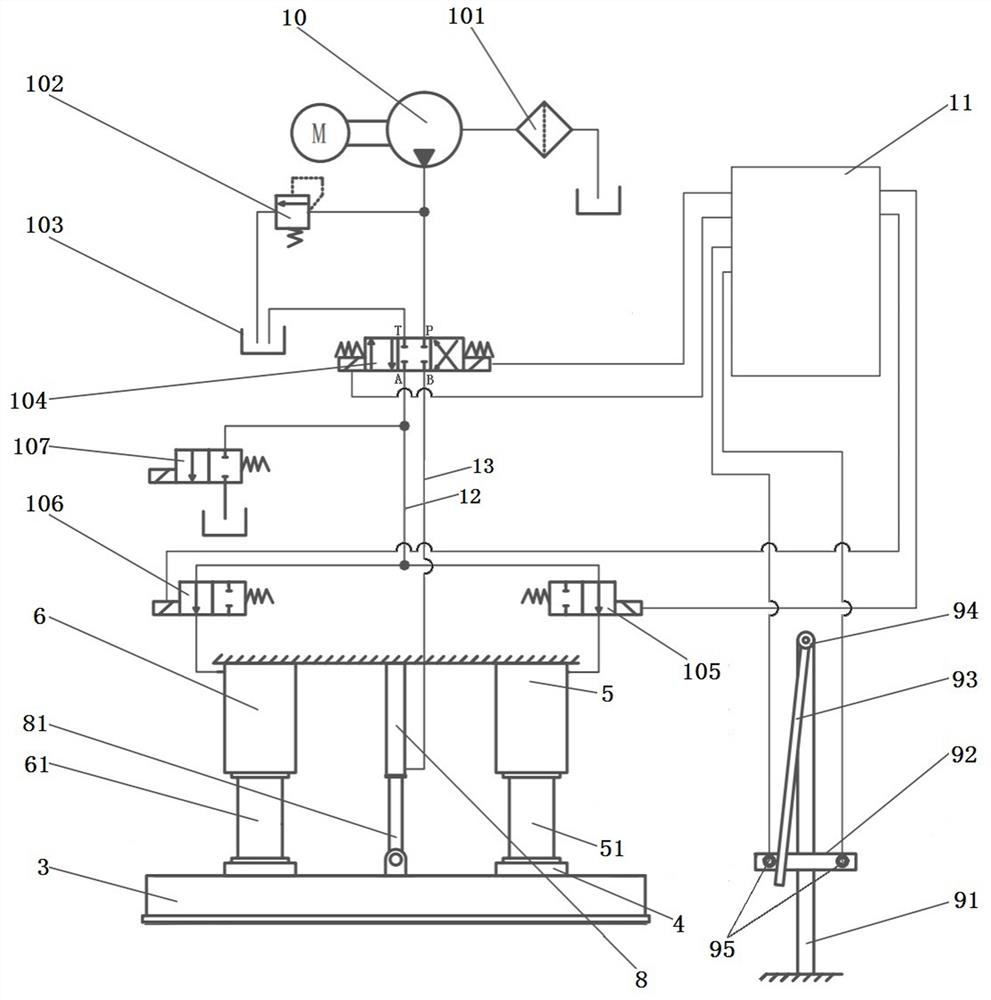

[0024]A displacement balance control device for a movable platen on a cold press, comprising a left hydraulic cylinder 6, a right hydraulic cylinder 5, a tie rod cylinder 8, an oil circuit system, a central control system 11 based on PLC, and a platen balance detection device 9; The platen balance detection device 9 is arranged on the platen 3 of the cold press 1, and the platen balance detection device 9 includes a swing rod 93, a vertical column 91 and a crossbeam 92 fixedly connected by a cross, and the vertical column 91 is vertically and fixedly installed on the cold press. On the pressing plate 3 of the press 1, a pin shaft 94 is provided on the top side of the column 91, and one end of the swing rod 93 is connected with the pin shaft 94 and rotates around the pin shaft 94. The cross beam 92 is opposite to the swing rod 93 Photoelectric switches 95 are symmetrically arranged at both ends of one side of the side, and each photoelectric switch 95 is connected with the centr...

Embodiment 2

[0033] Such as Figure 1~2 As shown, a displacement balance control device for a movable platen on a cold press, which includes a left hydraulic cylinder 6, a right hydraulic cylinder 5, a tie rod cylinder 8, an oil circuit system, a central control system 11 based on PLC, and a pressure plate balance detection device 9. The platen balance detection device 9 is arranged on the platen 3 of the cold press 1, and the platen balance detection device 9 includes a swing rod 93, a column 91 and a beam 92 fixedly connected by a cross, and the column 91 is vertically fixed Installed on the platen 3 of the cold press 1, the top side of the column 91 is provided with a pin 94, one end of the swing rod 93 is connected with the pin 94 and rotates around the pin 94, and the crossbeam 92 and the pendulum Both ends of the opposite side of the rod 93 are symmetrically provided with photoelectric switches 95, and each photoelectric switch 95 is connected with the central control system 11 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com